Choosing a 1300W motor cargo e-bike offers superior power, torque, and speed, making it ideal for carrying heavy loads and climbing steep hills effortlessly. This motor size enhances acceleration, extends range efficiency, and ensures reliable performance on diverse terrains, including rough urban roads, sand, and snow. For cargo e-bikes, the 1300W motor delivers unmatched versatility, durability, and ride quality.

What Advantages Does a 1300W Motor Provide for Cargo E-Bikes?

A 1300W motor significantly boosts torque and power output compared to lower wattage motors, enabling rapid acceleration and maintaining high speeds even on challenging terrains. This power allows cargo e-bikes to haul heavier loads—up to 450 lbs—without strain, making uphill climbs smoother and reducing rider fatigue. The motor’s higher voltage (typically 48V) supports consistent power delivery, improving overall ride stability and battery efficiency.

| Motor Wattage | Max Speed (mph) | Torque (Nm) | Terrain Capability |

|---|---|---|---|

| 500W | 20 | 50 | Flat roads, light trails |

| 750W | 25 | 65 | Moderate hills, mixed terrain |

| 1300W | 28+ | 85 | Steep hills, off-road, snow |

How Does a 1300W Motor Improve Hill Climbing and Load Capacity?

The 1300W motor delivers high torque—around 85 Nm—allowing cargo e-bikes to conquer steep inclines up to 30% grades effortlessly, even when fully loaded. This torque reduces the need for excessive pedaling, preserving rider energy and preventing motor overheating. Its thermal management and robust construction enable sustained climbs without performance loss, critical for heavy cargo transport or hilly urban environments.

Why Is the 48V Battery System Optimal for 1300W Cargo E-Bikes?

A 48V battery system paired with a 1300W motor offers efficient power delivery, reducing voltage drop and heat generation. This synergy ensures the motor runs smoothly at high speeds and under heavy loads. Higher voltage also enables faster charging and longer range, essential for cargo e-bikes that require endurance for daily commutes or delivery routes.

| Feature | Benefit |

|---|---|

| Higher Voltage | Improved torque and acceleration |

| Reduced Current | Less energy loss and heat |

| Efficient Charging | Faster recharge times |

| Compatibility | Supports high-power components |

What Terrain and Conditions Benefit Most from a 1300W Motor Cargo E-Bike?

Urban hills, rural roads, and uneven surfaces benefit most from a 1300W motor cargo e-bike. It delivers the strength to overcome gradients and poor terrain while fully loaded. Weather challenges like wind or rain are easier to manage with the motor’s torque support, making it ideal for all-weather commuting.

1300W motor cargo e-bikes excel on varied terrains including:

- Steep hills and mountainous routes

- Rough surfaces such as sand, snow, and mud

- Urban environments with frequent stop-and-go traffic

- Off-road trails requiring quick acceleration and torque

The motor’s power combined with fat tires and suspension enhances stability, traction, and rider confidence in all these conditions.

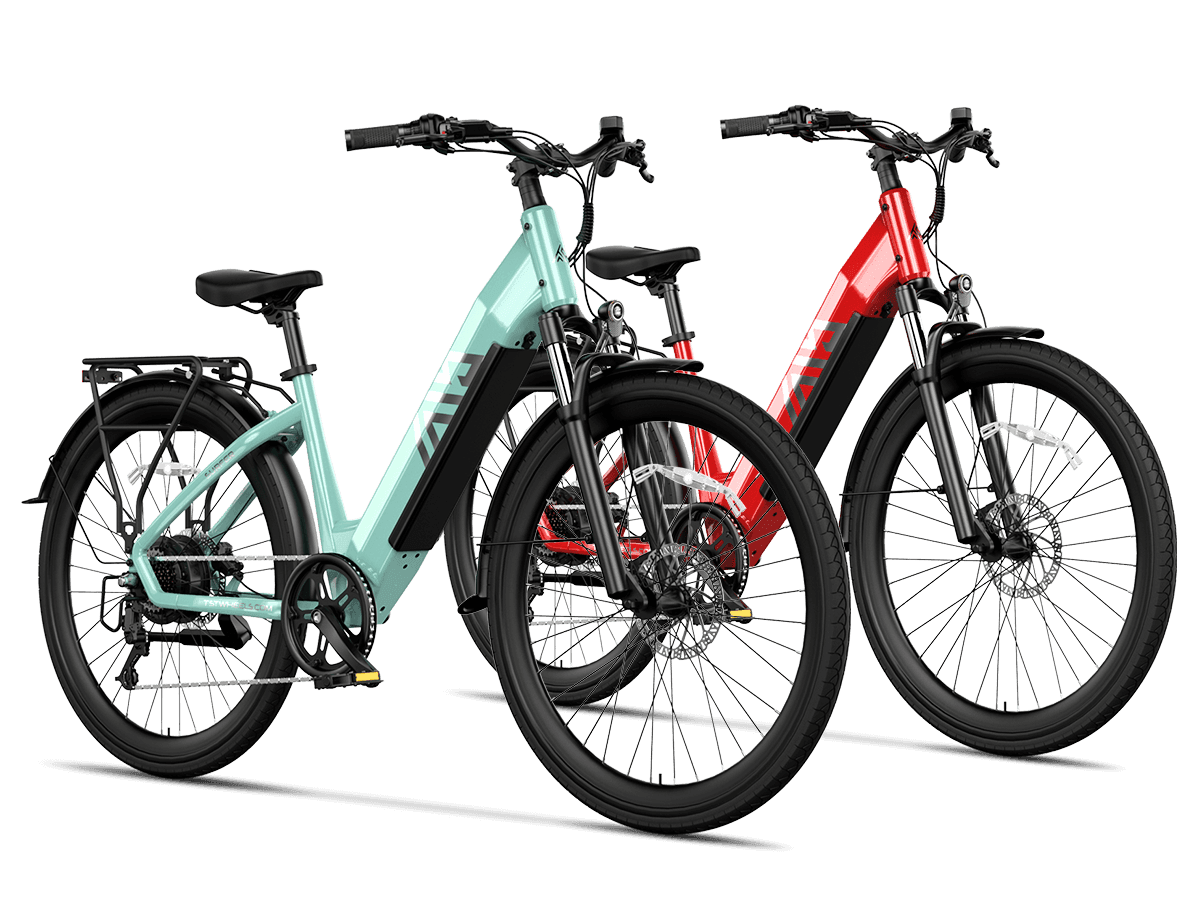

Which TST EBike Models Feature 1300W Motors for Cargo Use?

Select TST Ebike models feature 1300W motors tailored for hauling, such as those with reinforced frames, rear racks, and long-range battery support. These models are engineered for dependable utility, combining power, comfort, and safety for professional and personal cargo transport in demanding environments.

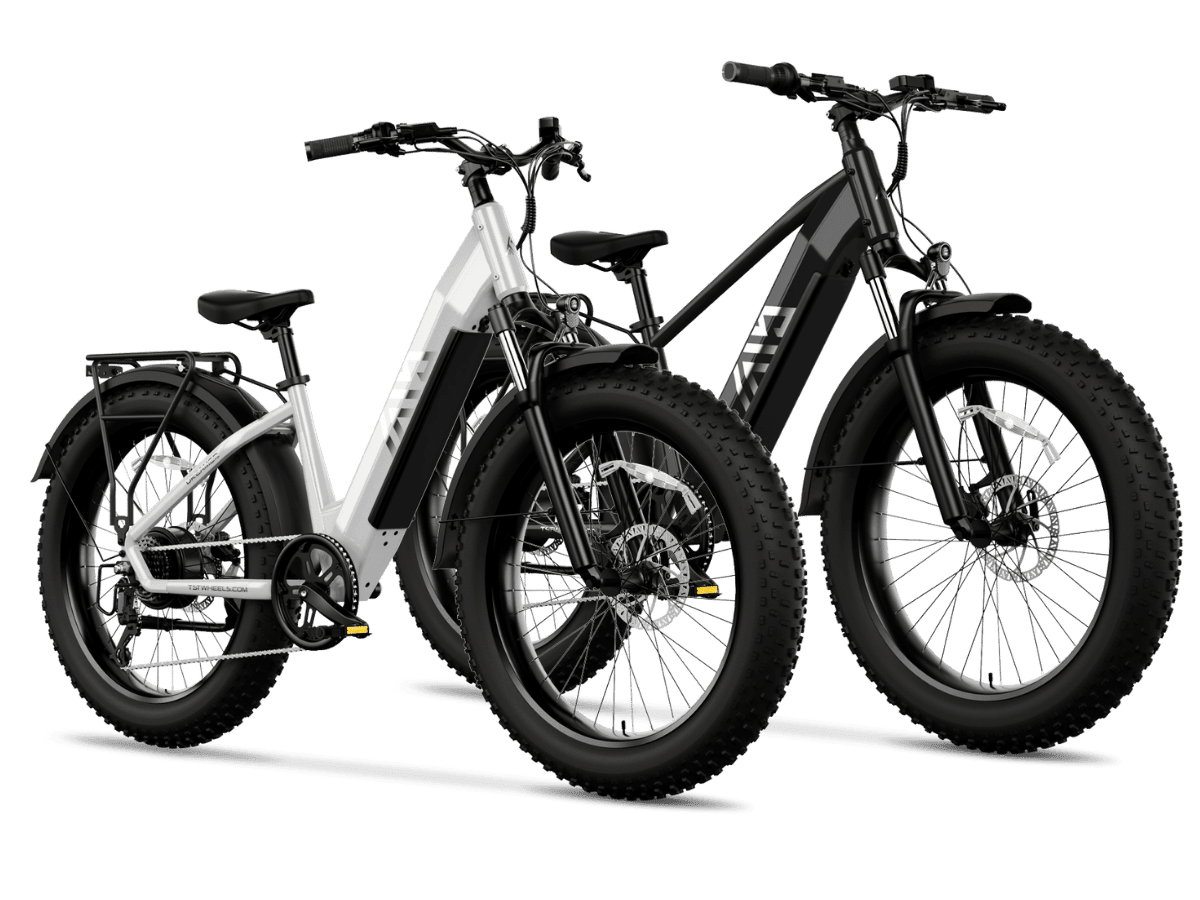

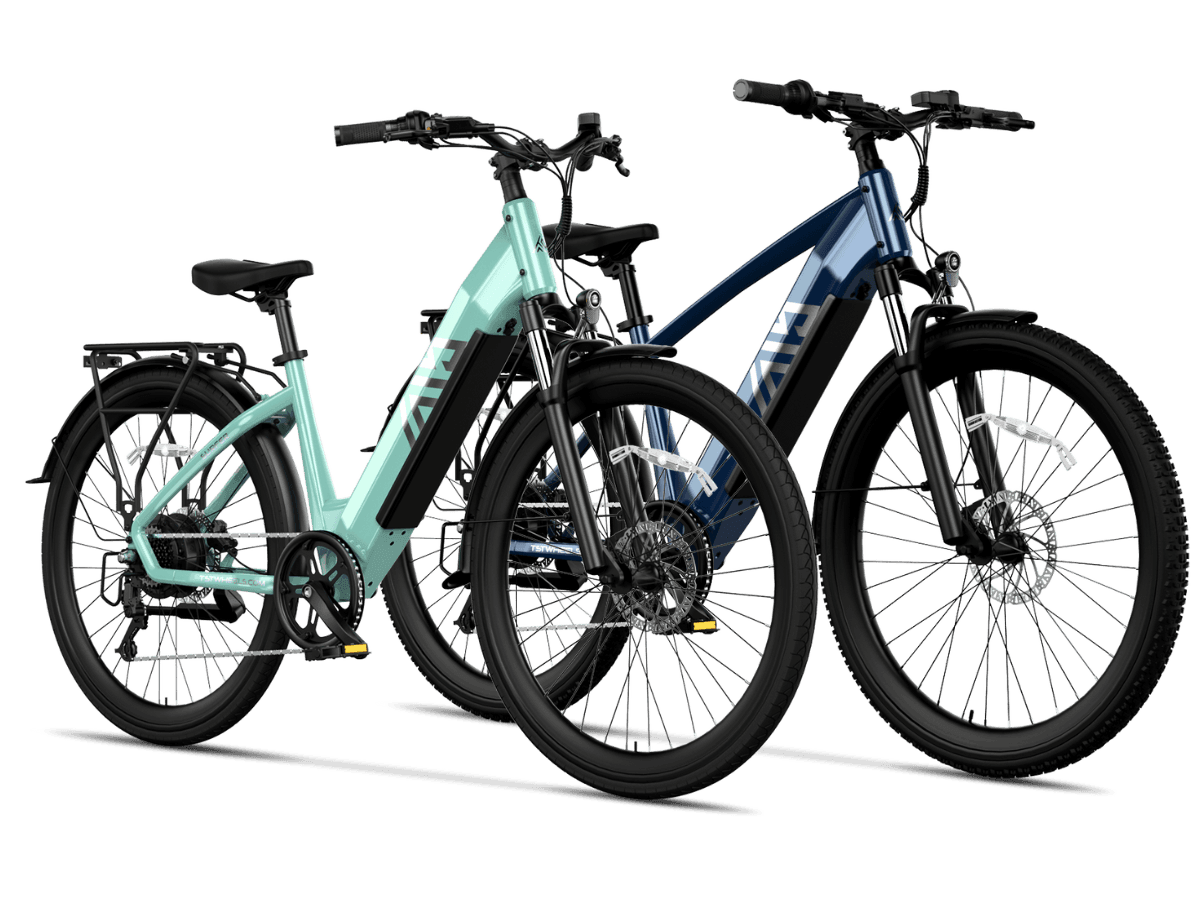

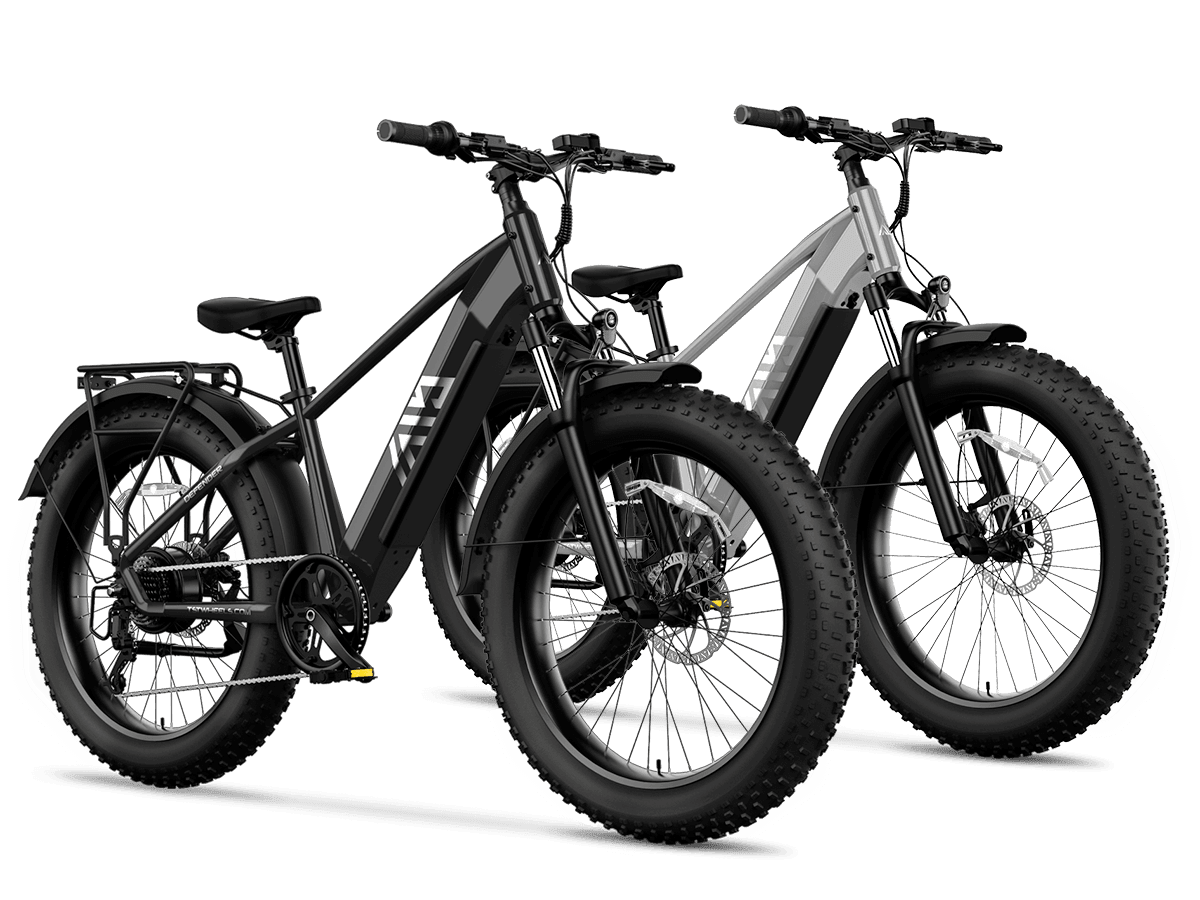

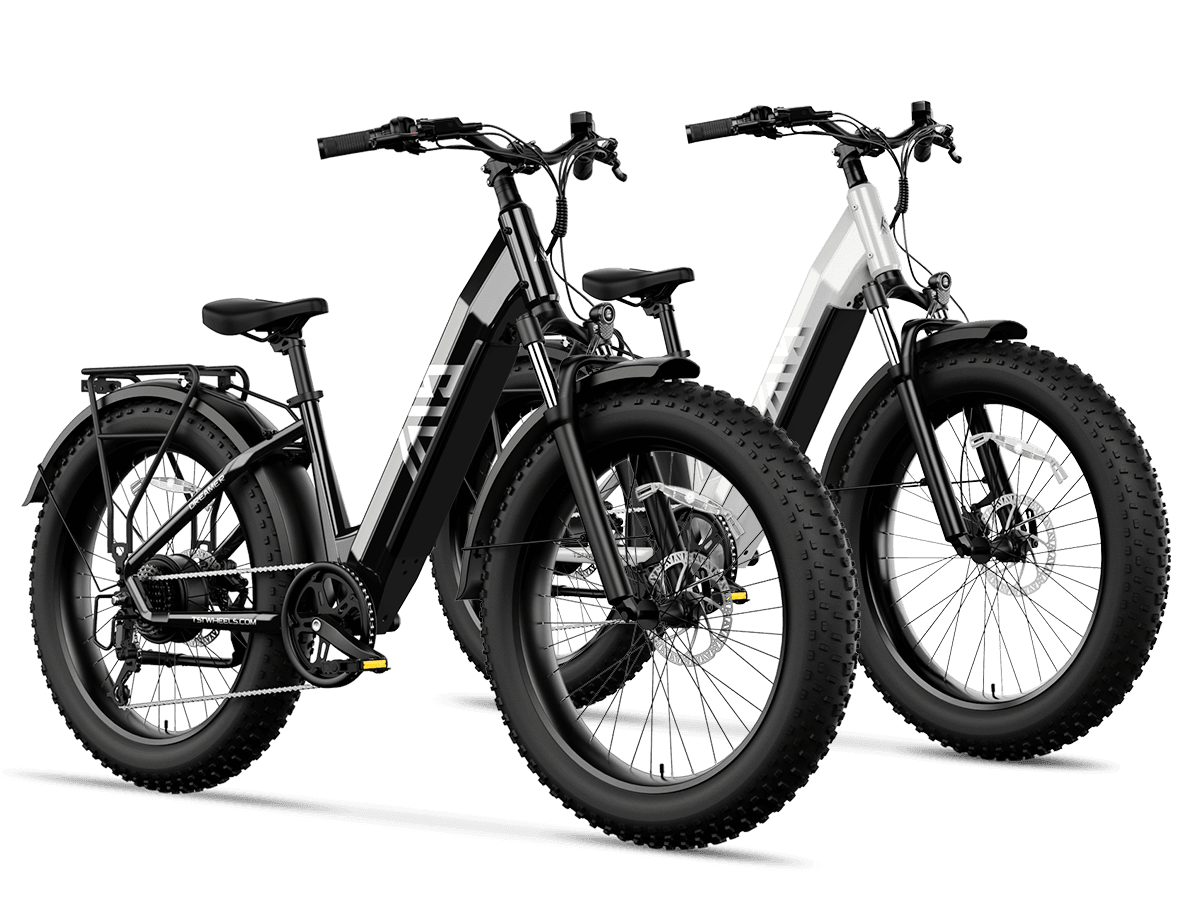

TST EBike integrates 1300W motors in its flagship cargo e-bikes:

- 26-inch models: Built for rugged terrains like snow and sand, these models leverage the 1300W motor for superior torque and control.

- 27-inch models: Designed for daily commuting and mountain biking, the 1300W motor ensures smooth hill climbing and fast cruising with heavy loads.

Both models emphasize high power, durability, and cost-effectiveness, making them ideal for demanding cargo applications.

How Does a 1300W Motor Affect Battery Life and Range?

While 1300W motors consume more energy under full throttle, efficient gear systems like Shimano 7-speed transmissions help optimize power use. This synergy extends battery life by reducing strain during climbs and heavy loads. Typical ranges for 48V 15Ah batteries paired with 1300W motors reach up to 60 miles under mixed riding conditions, balancing power and endurance.

Why Is a 1300W Motor Cargo E-Bike a Better Investment?

A 1300W cargo e-bike is a smart investment due to its durability and versatility. It supports higher payloads, handles varied terrain, and reduces dependence on cars for transport. With trusted brands like TST Ebike, buyers gain long-term value, backed by innovation, safety, and consumer-focused design.

Investing in a 1300W motor cargo e-bike means gaining:

- Enhanced versatility for various cargo and terrain challenges

- Reduced rider fatigue due to powerful motor assistance

- Longer-lasting components designed for high torque and frequent use

- Greater safety and control on steep or uneven surfaces

- Improved speed and acceleration for time-efficient commutes

This combination offers superior value for riders needing dependable, powerful cargo transport.

Buying Tips

When selecting a 1300W motor cargo e-bike, consider:

- Motor and Controller Quality: Ensure components are rated for 1300W continuous output to avoid overheating.

- Battery Compatibility: Choose a 48V battery system with sufficient amp-hours (15Ah or more) for extended range.

- Frame and Suspension: Opt for sturdy frames and front suspension to handle heavy loads and rough terrain.

- Drivetrain: Shimano 7-speed transmissions complement 1300W motors by optimizing power delivery and efficiency.

- Warranty and Service: Buy from reputable brands like TST EBike that offer solid warranties and responsive support.

- Intended Use: Match the e-bike model to your terrain and cargo needs, choosing 26-inch models for rough terrain or 27-inch for urban and mountain use.

These tips ensure you maximize performance, durability, and satisfaction with your 1300W motor cargo e-bike.

TST EBike Expert Views

“TST EBike’s 1300W motor cargo e-bikes are engineered to deliver unmatched power and reliability for heavy-duty riders. Our 26-inch and 27-inch models combine high torque motors with Shimano 7-speed transmissions and robust battery systems to conquer steep hills and carry substantial cargo effortlessly. We prioritize quality control and customer feedback to ensure every e-bike meets rigorous performance and safety standards, offering riders a versatile and cost-effective transportation solution.” – TST EBike Engineering Team

FAQs

Is a 1300W motor legal for street use?

In many regions, 1300W motors exceed legal limits for public roads but are permitted on private property or off-road.

How heavy is a 1300W motor cargo e-bike?

Typically between 60-70 lbs, depending on frame and battery size, balancing power with manageable weight.

Does a 1300W motor consume more battery?

Yes, but efficient transmissions and riding habits can mitigate excessive drain, maintaining practical range.

Can I upgrade my e-bike to a 1300W motor?

Only if the frame, battery, and controller support higher wattage; professional consultation is recommended.

How does a 1300W motor compare to 750W?

It offers nearly double the torque and higher speeds, ideal for steep hills and heavy cargo, at the cost of increased energy use.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.