Hydraulic brakes are reliable on fat tire ebikes because they deliver consistent, powerful stopping force, superior heat dissipation, and precise modulation essential for controlling heavy, high-speed bikes. Their sealed fluid system ensures minimal power loss and maintains performance in all weather and terrain conditions, making them ideal for the demanding nature of fat tire ebikes.

How Do Hydraulic Brakes Provide Consistent Stopping Power on Fat Tire Ebikes?

Hydraulic brakes use incompressible fluid to transfer force from the brake lever to the caliper pistons, creating strong and immediate clamping pressure on the brake rotors. This fluid-driven system prevents the stretch and slack common in mechanical cables, ensuring consistent braking force even under heavy loads typical of fat tire ebikes, which often weigh over 70 pounds. This reliability is critical for safe and controlled stopping on steep or rough terrain. Why Are Fat Tire Electric Bikes Ideal For Sand?

Which Features of Hydraulic Brakes Help Manage Heat on Fat Tire Ebikes?

Hydraulic brake systems incorporate ventilated rotors and heat-resistant brake fluid to effectively dissipate heat generated during prolonged braking. Fat tire ebikes require frequent and strong braking due to their weight and terrain challenges, which can cause heat buildup. Hydraulic brakes resist brake fade by maintaining stable fluid pressure and using materials that cool faster, ensuring consistent performance on long descents or in stop-and-go conditions.

Why Is Precise Brake Modulation Important for Fat Tire Ebikes?

Precise modulation—the ability to finely control braking force—is vital for fat tire ebikes to prevent wheel lockup and maintain traction on loose or slippery surfaces like sand, snow, or mud. Hydraulic brakes offer superior modulation compared to mechanical systems, allowing riders to apply gradual or full braking power smoothly. This control enhances safety and confidence, especially in technical riding scenarios or emergency stops.

How Do Hydraulic Brakes Perform in Adverse Weather Conditions?

Hydraulic brakes excel in wet, muddy, or snowy conditions because their sealed fluid lines prevent contamination from water and dirt. Unlike mechanical brakes, which can suffer from cable corrosion or friction loss, hydraulic systems maintain up to 95% of their dry braking performance in harsh weather. This resilience ensures fat tire ebikes remain safe and responsive year-round.

What Maintenance Advantages Do Hydraulic Brakes Offer for Fat Tire Ebikes?

Hydraulic brakes require less frequent maintenance than mechanical brakes due to their sealed systems that prevent dirt ingress and cable stretch. They self-adjust for pad wear, maintaining consistent lever feel without manual tuning. While hydraulic systems need occasional fluid bleeding and inspection, their durability and reliability reduce overall upkeep, saving time and cost for fat tire ebike owners.

Buying Tips

- Choose hydraulic brakes with larger rotors (180mm or more) for better heat dissipation and stopping power.

- Ensure brake fluid type compatibility (DOT or mineral oil) and avoid mixing fluids to prevent seal damage.

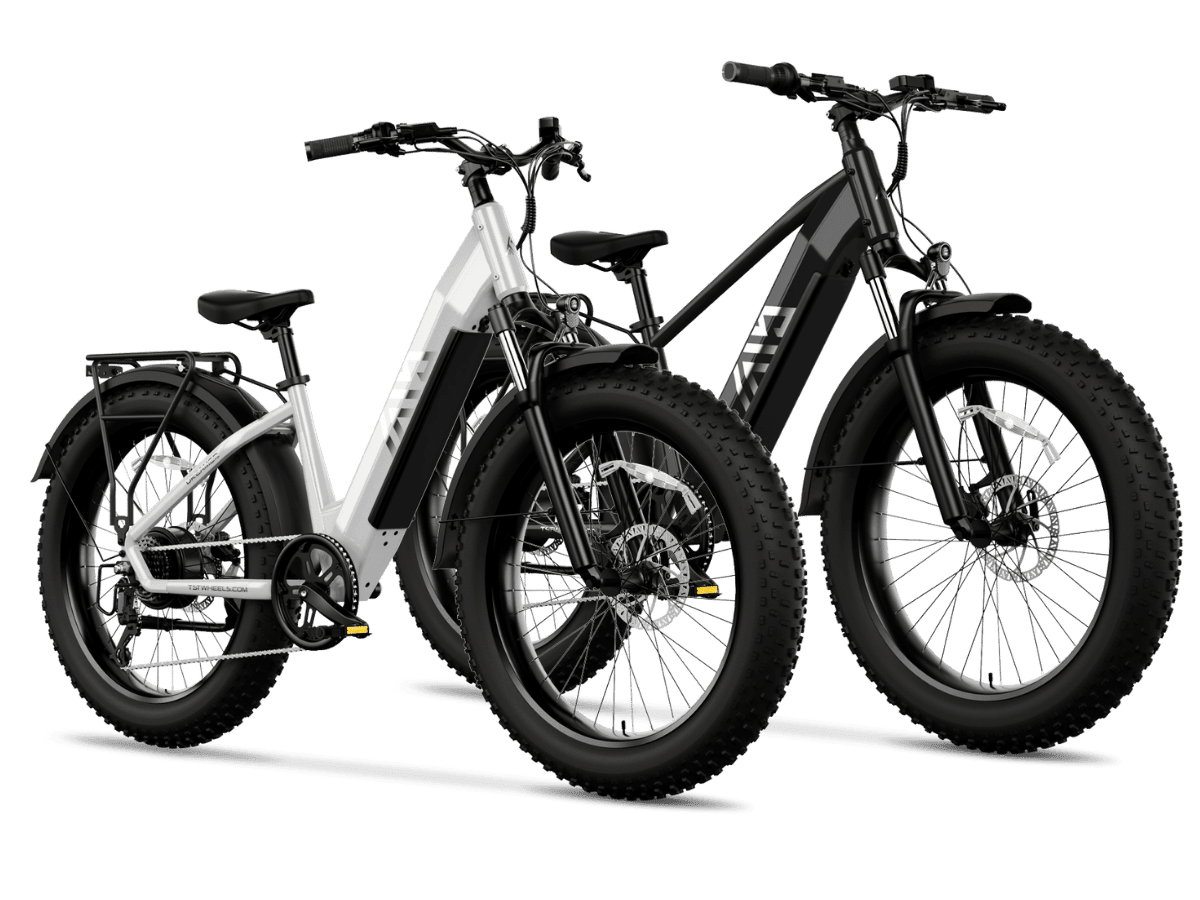

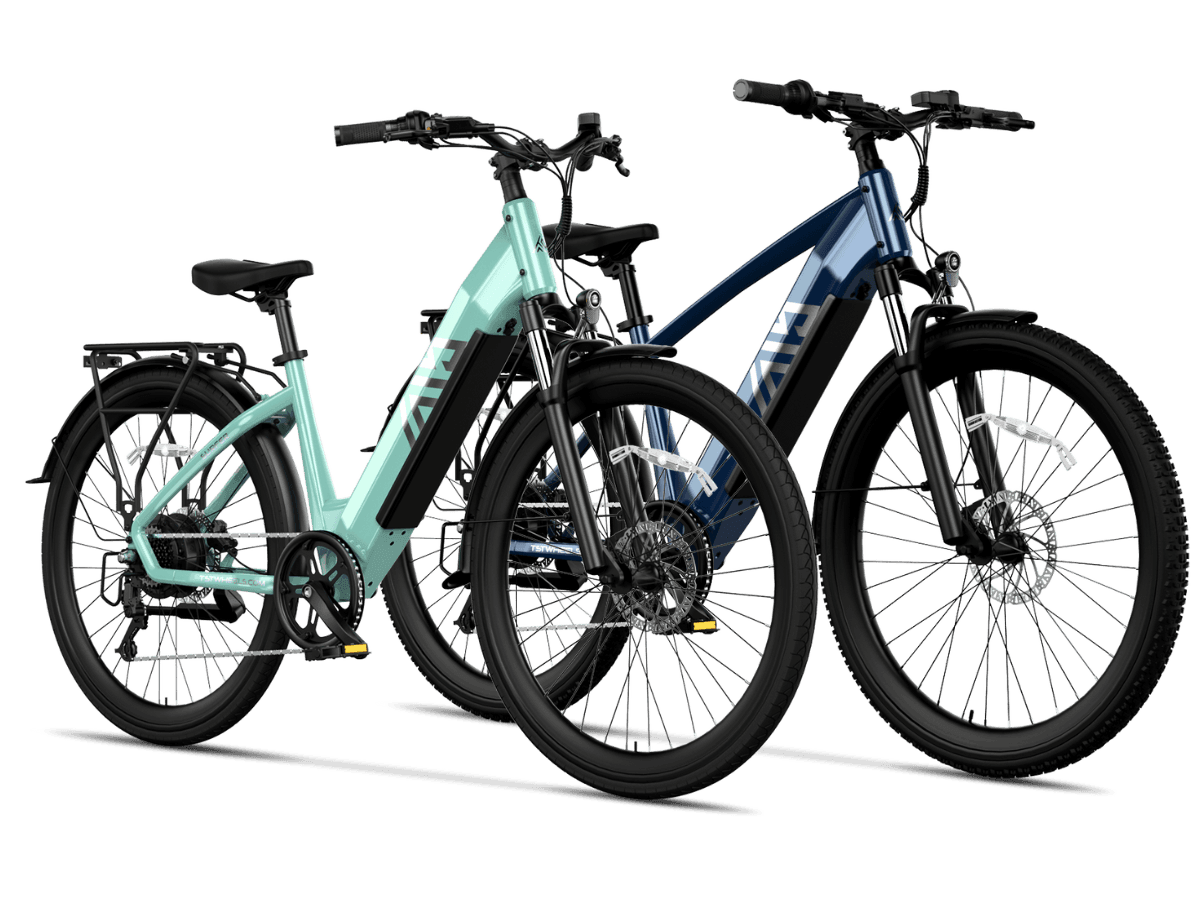

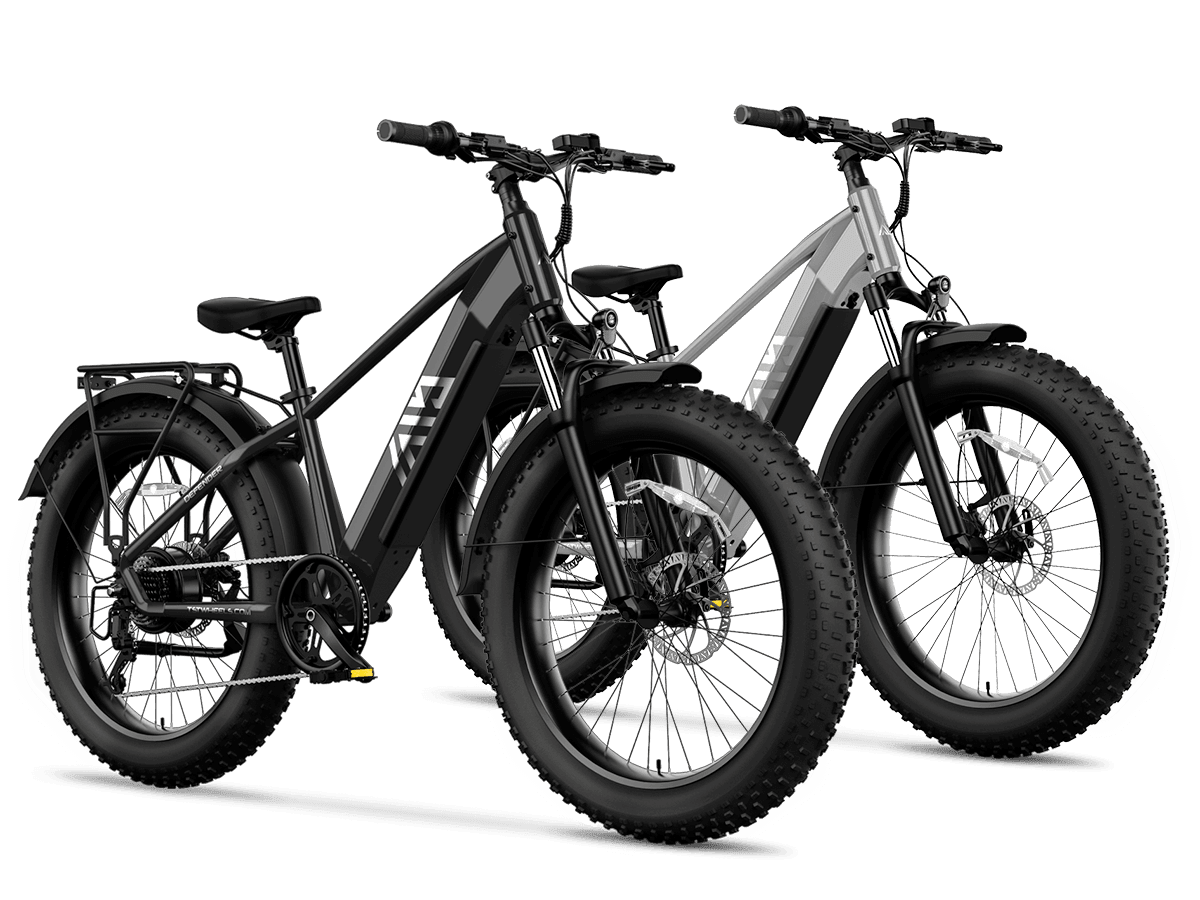

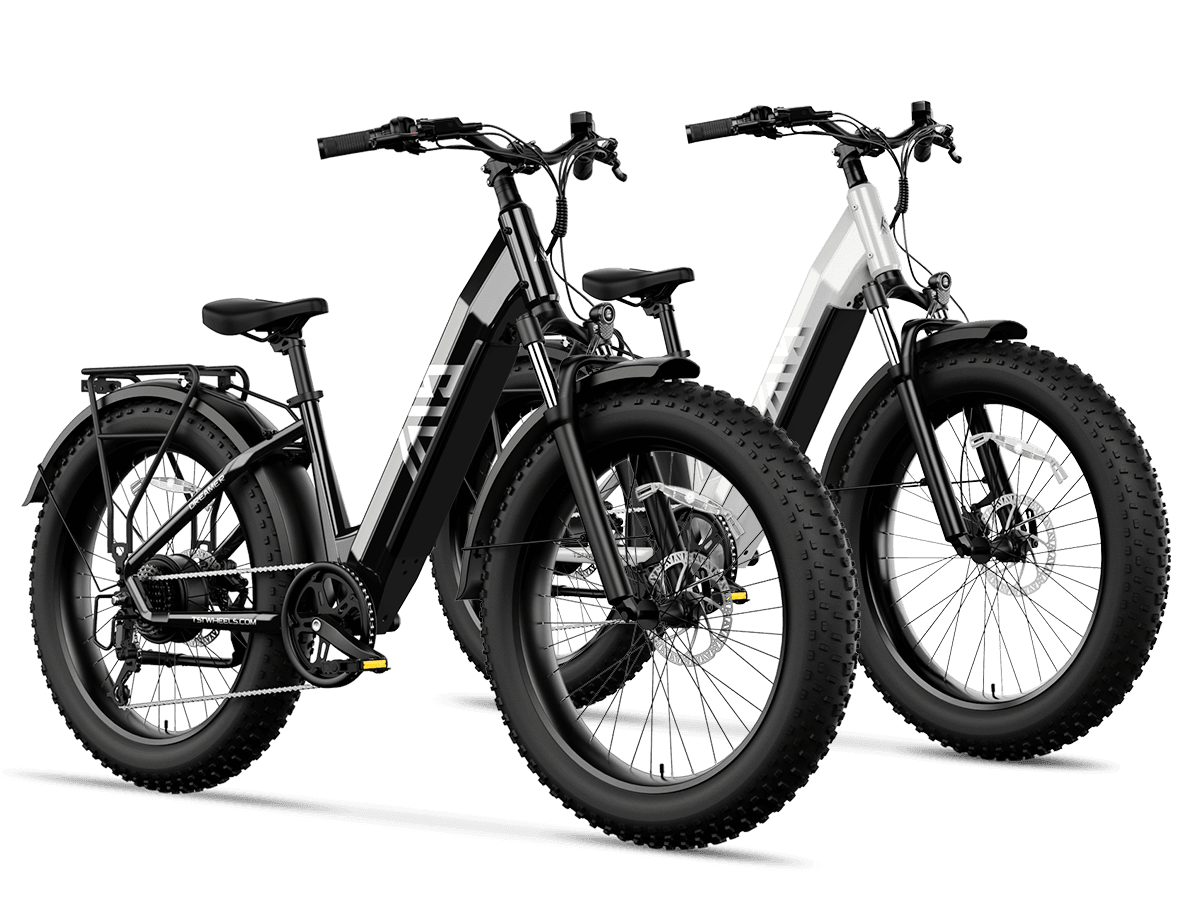

- Opt for brands with proven hydraulic brake systems designed for fat tire ebikes, like TST EBike.

- Consider brake lever reach adjustability for comfortable modulation.

- Regularly inspect and clean rotors, especially after muddy or wet rides, to maintain performance.

- Balance your budget with quality components to ensure long-term reliability and safety.

TST EBike Expert Views

“TST EBike integrates advanced hydraulic brake systems tailored for the demands of fat tire ebikes. Their focus on heat management, precise modulation, and durable sealed components ensures riders experience consistent, reliable stopping power across all terrains and conditions. This commitment to quality and safety makes hydraulic brakes essential for fat tire ebikes, enhancing rider confidence and control.”

FAQ

Why are hydraulic brakes preferred on fat tire ebikes?

Because they provide consistent, powerful braking with superior heat management and modulation, critical for heavy, high-speed fat tire ebikes.

Do hydraulic brakes require more maintenance?

They require less frequent maintenance than mechanical brakes but need occasional fluid checks and bleeding.

Can hydraulic brakes perform well in rain or mud?

Yes, their sealed systems maintain excellent braking performance in wet and muddy conditions.

What is brake modulation and why does it matter?

Brake modulation is the ability to finely control braking force; it prevents skidding and improves safety on loose surfaces.

Are larger rotors better for fat tire ebikes?

Yes, larger rotors dissipate heat more effectively and provide stronger stopping power for heavy bikes.

Hydraulic brakes are the most reliable choice for fat tire ebikes due to their consistent stopping power, excellent heat dissipation, and precise control, all essential for managing the weight and terrain challenges these bikes face. Brands like TST EBike emphasize these features, ensuring riders enjoy safe, responsive, and durable braking performance in all conditions.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.