A 1300W rear motor boosts electric bike performance by delivering high torque—typically 85 to 100 Nm—that enables rapid acceleration, superior hill climbing, and sustained speeds up to 28MPH. Positioned on the rear wheel, it maximizes traction and weight distribution, enhancing stability and control. Paired with a 48V battery and optimized controller, it offers powerful, efficient, and durable performance across diverse terrains.

How Does a 1300W Rear Motor Enhance Torque and Acceleration?

The 1300W motor generates immense torque, providing a strong twisting force that propels the bike forward quickly, even under heavy loads or steep inclines. Its rear placement improves traction by pushing power through the wheel bearing most rider weight, reducing wheel spin and improving launch control. Operating typically at 500-600 RPM, it converts torque into swift acceleration, allowing riders to climb 20%+ gradients without pedal assist.

Chart: Torque and Acceleration Benefits of a 1300W Rear Motor

| Feature | Benefit |

|---|---|

| 85-100 Nm Torque | Rapid acceleration and hill climbing |

| Rear Wheel Placement | Enhanced traction and reduced wheel slip |

| 500-600 RPM Speed | Efficient power conversion to speed |

Why Does Rear-Wheel Drive Improve Traction and Stability?

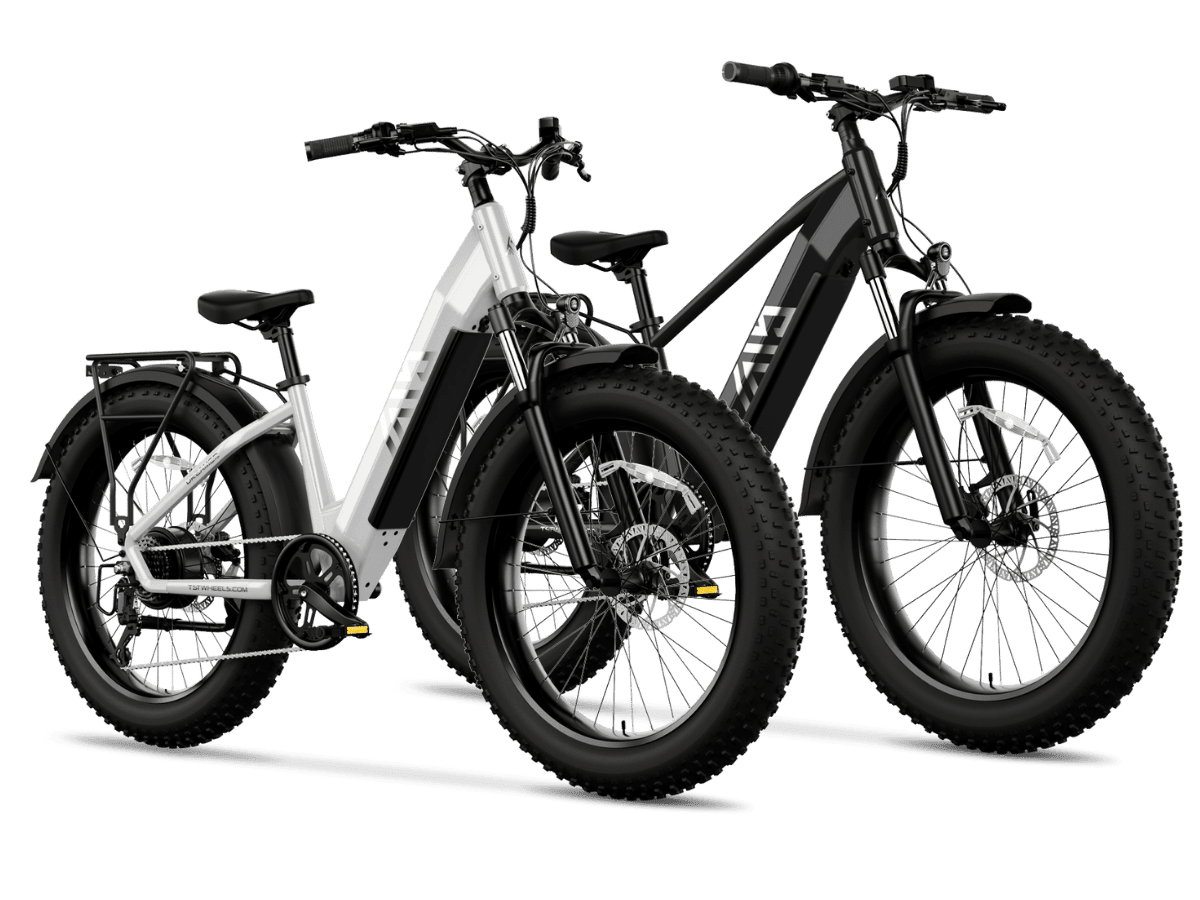

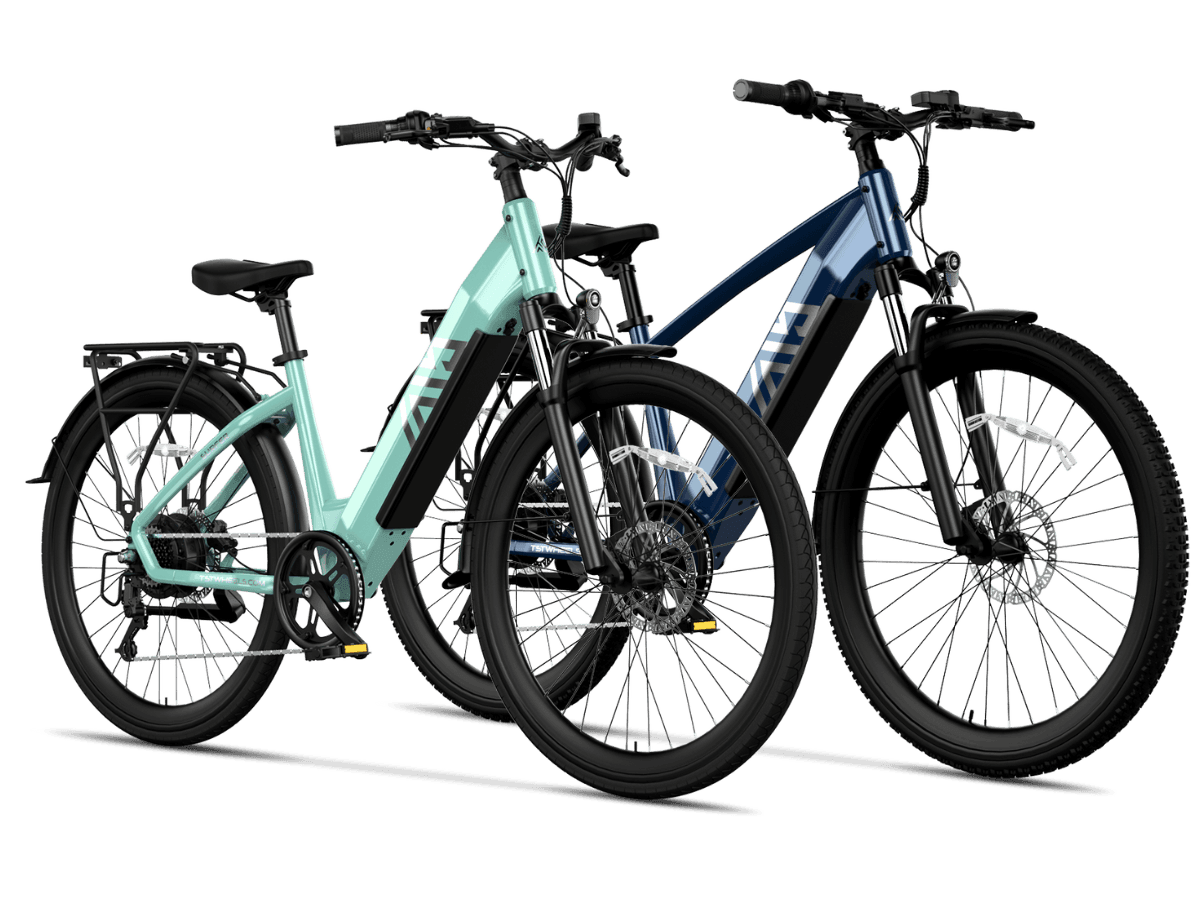

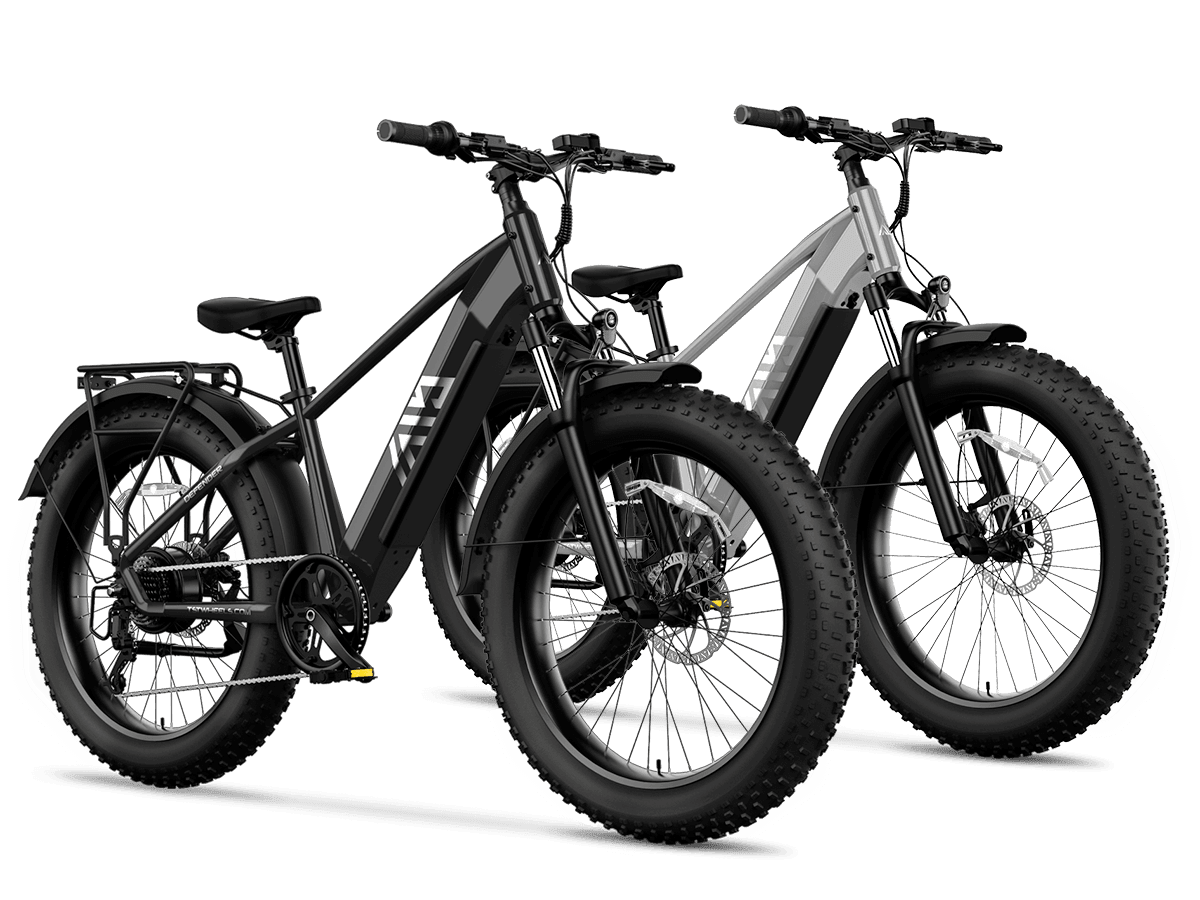

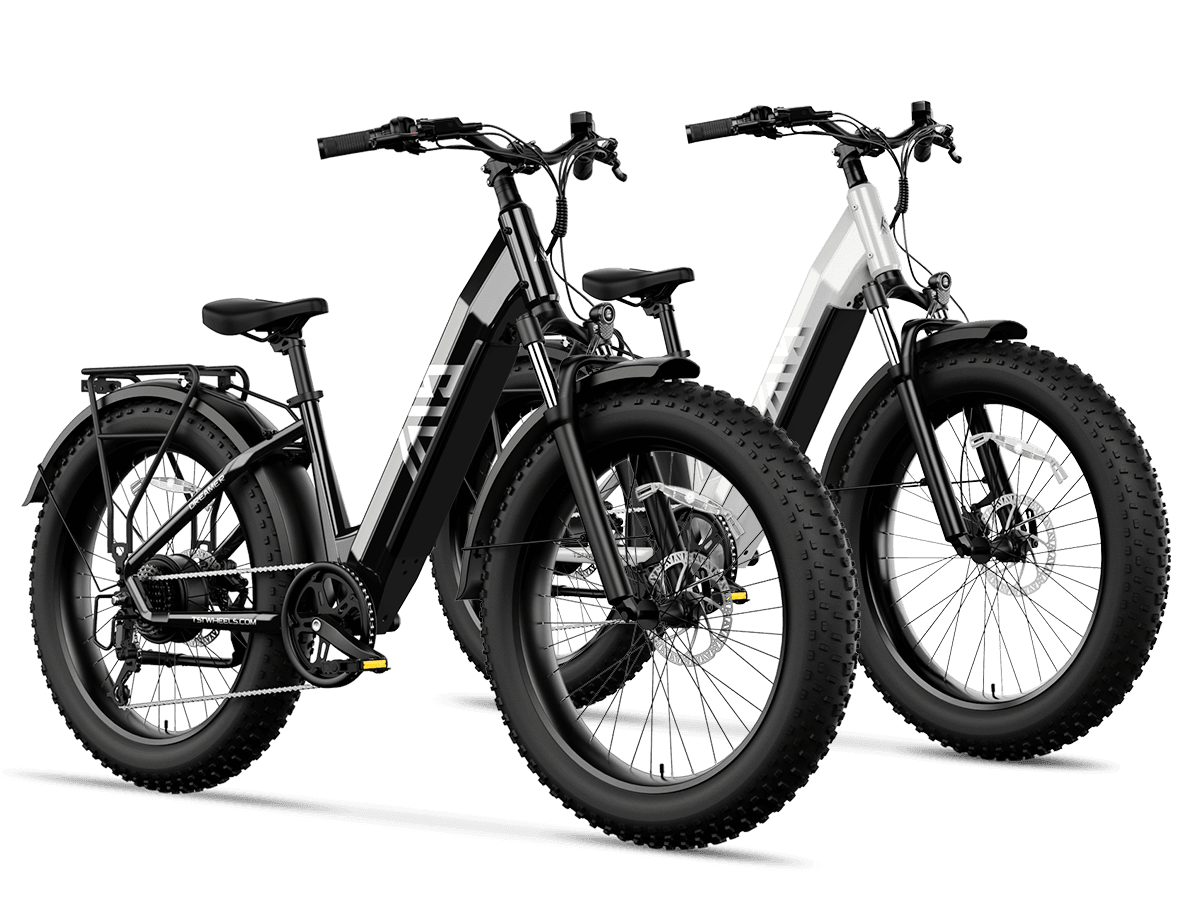

Rear-wheel drive motors deliver power where the rider’s weight naturally rests, increasing grip on loose or slippery surfaces such as sand, snow, or gravel. This setup provides a more natural feeling of acceleration and control, especially on hills or rough terrain. The improved weight distribution smooths ride experience and reduces the chance of front wheel slip, making the bike easier to handle at high speeds or under load.

How Does a 48V Battery Complement a 1300W Rear Motor?

A 48V battery supplies higher voltage, reducing current draw for the same power output, which minimizes heat buildup and energy loss. This efficient power delivery supports the 1300W motor’s high torque demands while extending battery life. Typically paired with a 15Ah capacity, it enables ranges up to 65 miles under pedal assist, balancing power and endurance for long rides.

What Role Do Fat Tires Play in Enhancing a 1300W Ebike’s Performance?

Fat tires, usually 26” x 4”, increase ground contact area, improving grip and shock absorption on challenging terrains like snow, sand, and mud. Their wider footprint prevents sinking and spinning out when the powerful 1300W motor applies torque. Running at low tire pressures, fat tires cushion impacts, enhancing ride comfort and control during rapid acceleration or climbing.

Chart: Fat Tires and Performance Impact

| Tire Feature | Performance Benefit |

|---|---|

| Wide 4-inch Width | Superior traction on loose terrain |

| Low Tire Pressure | Shock absorption and ride comfort |

| Larger Contact Area | Prevents wheel slip under high torque |

How Does a 1300W Rear Motor Affect Battery Range and Efficiency?

While a 1300W motor consumes more power at full throttle, intelligent pedal assist and efficient controllers optimize energy use, extending battery range. For example, at 28MPH, a 48V 15Ah battery can last 60-65 miles using moderate pedal assist. Maintaining steady speeds and using gears effectively reduces motor strain and conserves battery life, balancing power with endurance.

What Safety and Durability Features Support a 1300W Rear Motor Ebike?

Powerful motors require robust braking systems—hydraulic disc brakes with 180mm rotors are common for reliable stopping power. Reinforced aluminum frames withstand motor torque and rider weight without flexing. Thermal management systems in the motor and controller prevent overheating during intense use, ensuring durability and consistent performance.

Buying Tips

When selecting a 1300W rear motor ebike, consider:

- Motor torque (85 Nm or higher) for strong acceleration and hill climbing.

- A 48V 15Ah or larger battery for sustained power and range.

- Fat tires (26” x 4” or wider) for traction and comfort.

- Hydraulic disc brakes for safe stopping at high speeds.

- Durable frame materials like aluminum or chromoly steel.

- Quality controllers and thermal management for motor longevity.

Test rides and checking manufacturer specs help ensure the bike meets your power and terrain needs.

TST EBike Expert Views

“TST EBike’s 1300W rear motor models combine high torque with efficient 48V battery systems and wide fat tires to deliver exceptional acceleration, hill climbing, and stability. Our engineering focuses on thermal management and durable frames, providing riders with reliable performance across urban and off-road environments while supporting up to 500 lbs.” – TST EBike Product Specialist

FAQ

Is a 1300W rear motor suitable for steep hills?

Yes, its high torque enables climbing inclines over 20% without pedal assist.

How does rear-wheel drive compare to mid-drive motors?

Rear-wheel drive offers better traction and simpler maintenance, especially on loose terrain, while mid-drive motors excel in gear efficiency.

What battery capacity pairs best with a 1300W motor?

A 48V 15Ah battery balances power delivery and range effectively.

Are fat tires necessary with a 1300W rear motor?

While not mandatory, fat tires greatly enhance traction and control when applying high torque on varied terrain.

A 1300W rear motor boosts electric bike performance by delivering powerful torque, improving traction through rear-wheel drive, and pairing with efficient 48V batteries and fat tires to offer rapid acceleration, hill climbing, and stable handling across diverse terrains.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.