A high-torque 1300W rear-drive ebike combines a powerful 1300-watt rear hub motor with substantial torque—typically over 90 Nm—to deliver exceptional acceleration, hill-climbing capability, and traction that excels in rough terrain, cargo hauling, and off-road adventures—all while offering improved load-carrying stability.

What is a high-torque 1300W rear-drive ebike?

A high-torque 1300W rear-drive ebike is an electric bicycle equipped with a 1300-watt motor mounted on the rear wheel hub that delivers elevated torque, often in the 85–160 Nm range. This setup ensures powerful acceleration and enhanced stability, perfect for steep climbs, carrying heavy loads, or navigating uneven terrains such as sand, snow, or gravel.

How does a 1300W rear hub motor and torque improve performance?

High torque from a 1300W rear hub motor generates strong rotational force (torque), propelling riders effortlessly uphill or under heavy payloads. The combination of high-torque and a 1300W rear-drive system enables rapid acceleration, improved responsiveness, and enhanced control on challenging inclines.

Chart: Motor Power vs Torque vs Speed

| Motor Wattage | Peak Torque (Nm) | Typical Top Speed (mph) |

|---|---|---|

| 750W | 60–75 | ~25 |

| 1000W | 75–85 | ~27 |

| 1300W | 85–160 | ~28+ |

Using a 1300W rear-drive configuration grants an e-bike superior speed, torque, and acceleration compared to lower-power and torque systems, making it ideal for demanding terrains and heavy-duty use.

Why choose a rear-drive motor configuration?

Rear-drive motors propel the bike by driving the rear wheel, improving traction—especially on loose or uneven surfaces—and enhancing stability under load. This setup simplifies drivetrain complexity, often lowers maintenance, and typically costs less than mid-drive systems. The weight over the rear wheel boosts grip on all terrains, offering reliable performance in sand, snow, hills, and rough surfaces.

What powertrain components (motor, battery, controller) define these ebikes?

A high-torque 1300W rear-drive ebike typically includes:

- Motor: A 1300W brushless geared hub motor delivering around 85-160 Nm torque, smooth acceleration, and quiet performance.

- Battery: A robust 48 V, 15 Ah lithium-ion pack (≈720 Wh) offering up to 50–65 miles of range, depending on terrain and assist level.

- Controller: A 20–22 A electronic unit regulating current flow, interpreting throttle or pedal-assist input, and balancing efficiency with performance.

Chart: Powertrain Components Overview

| Component | Specification | Benefit |

|---|---|---|

| Motor | 1300W, 85–160 Nm | Strong hill climbing and acceleration |

| Battery | 48 V 15 Ah (~720 Wh) | Long range and efficient power delivery |

| Controller | 20–22 A | Smooth throttle, safety, power control |

These components synergize to deliver reliable, sustained performance across varied terrains and riding demands.

How do fat tires, frame, suspension, and brakes enhance performance and safety?

- Fat Tires: Wider tires (4″ typical for 26″ or 27″ rims) offer larger contact patches, providing increased traction, enhanced comfort, puncture resistance, and better performance on sand, snow, rocks, or mud.

- Frame & Suspension: Sturdy aluminum or steel frames support heavy loads (up to ~500 lb) while front suspension (~80 mm travel) cushions bumps, improving control at speed.

- Hydraulic Disc Brakes: Dual 180 mm hydraulic rotors offer powerful, reliable stopping, essential for safely managing the ebike’s speed and weight.

- Additional Features: Integrated LED lighting, LCD displays, Shimano 7-speed drivetrains, and throttle or pedal-assist controls create an intuitive, comfortable, and safer riding experience.

These features work together to maximize the 1300W rear-drive’s capabilities, ensuring riders maintain control and comfort under performance-intensive conditions.

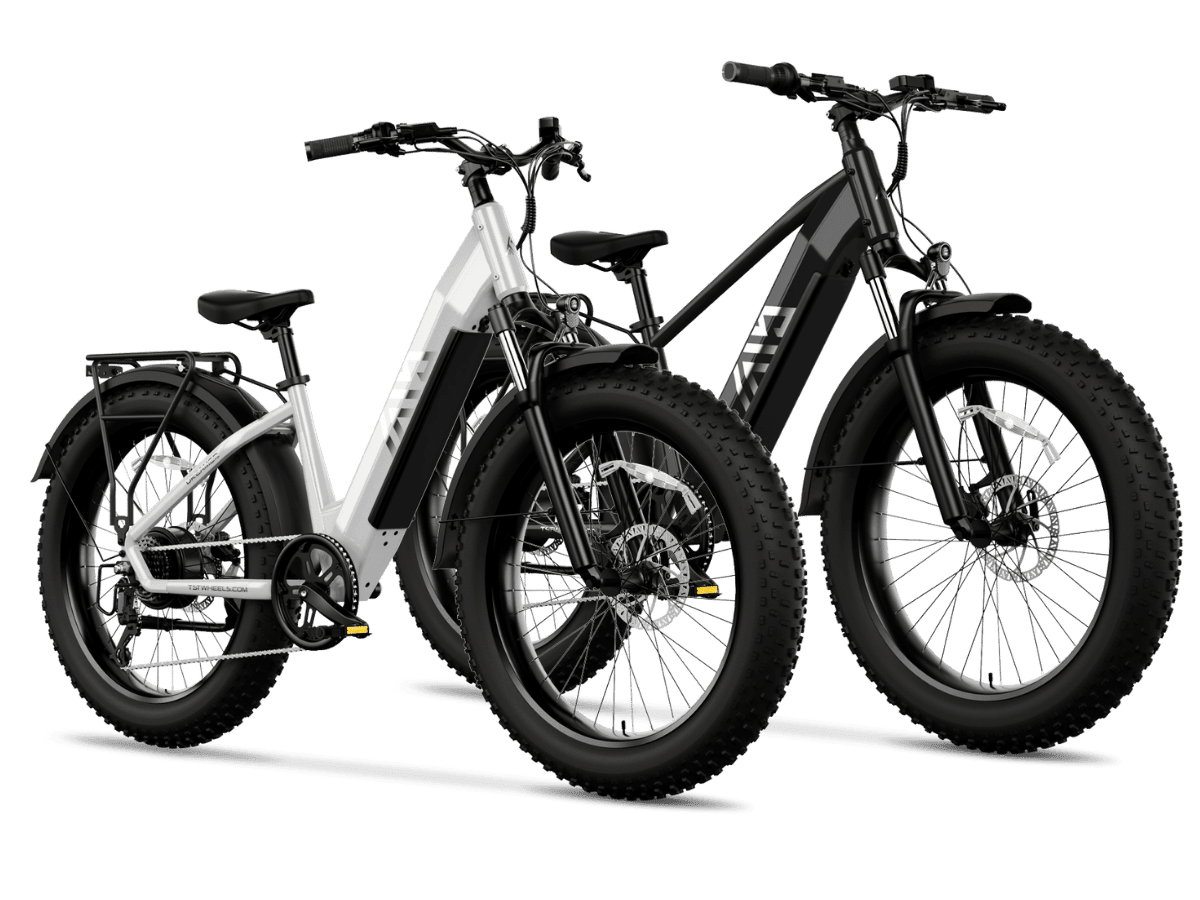

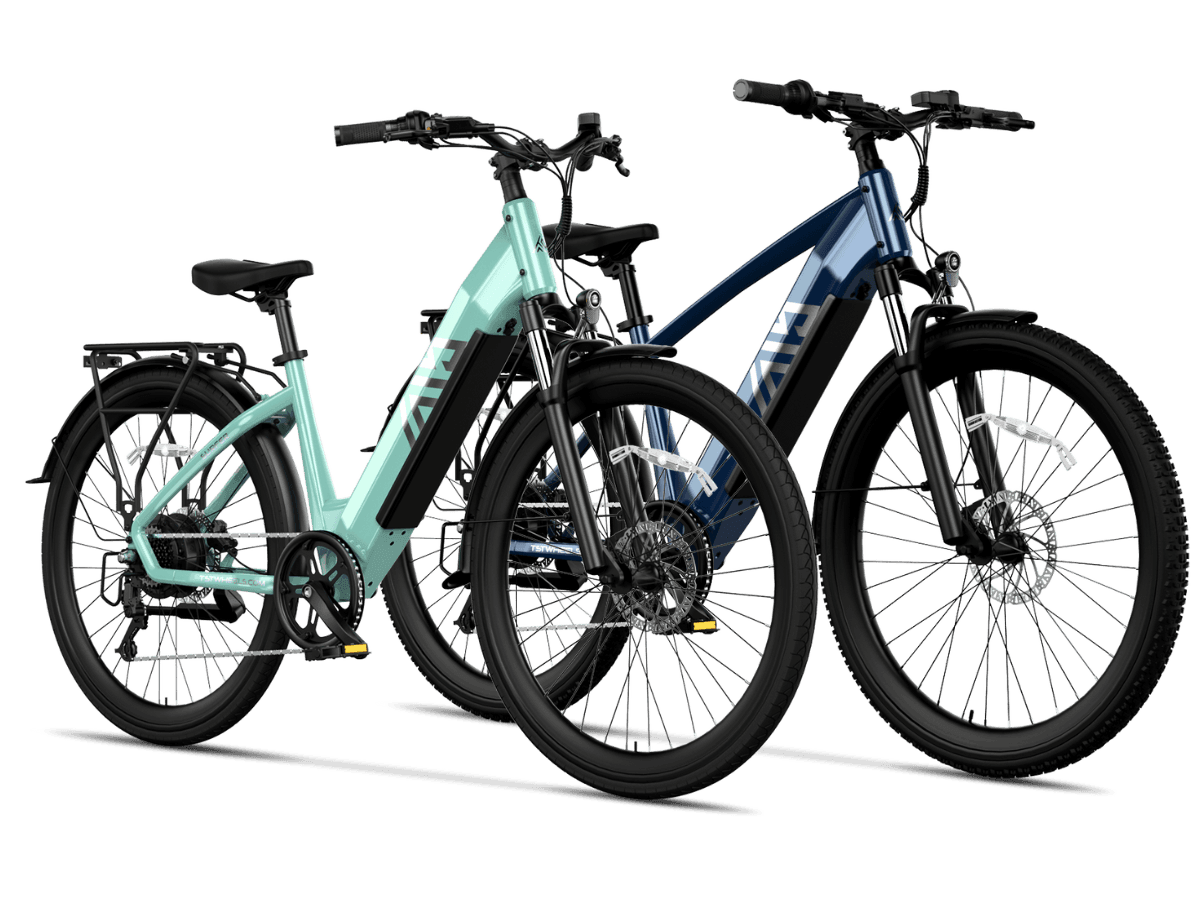

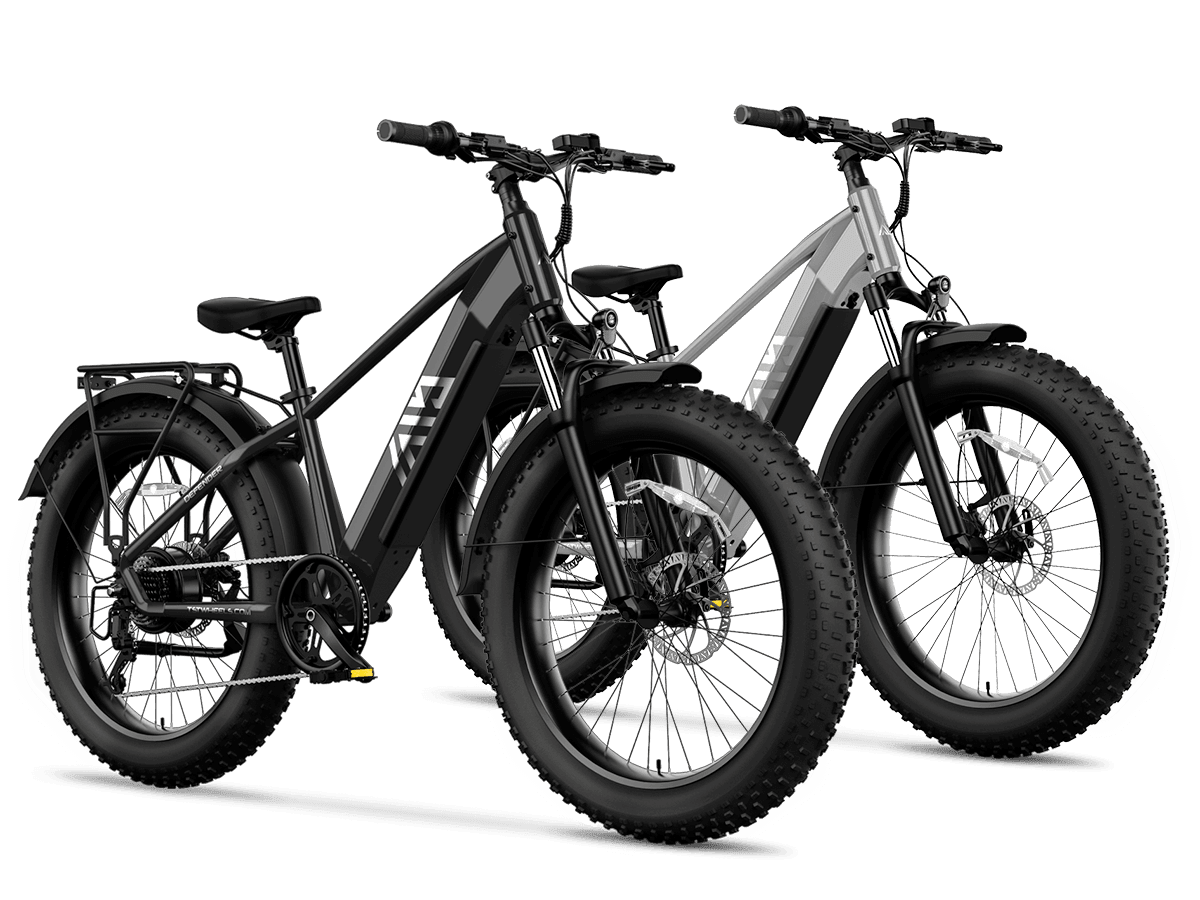

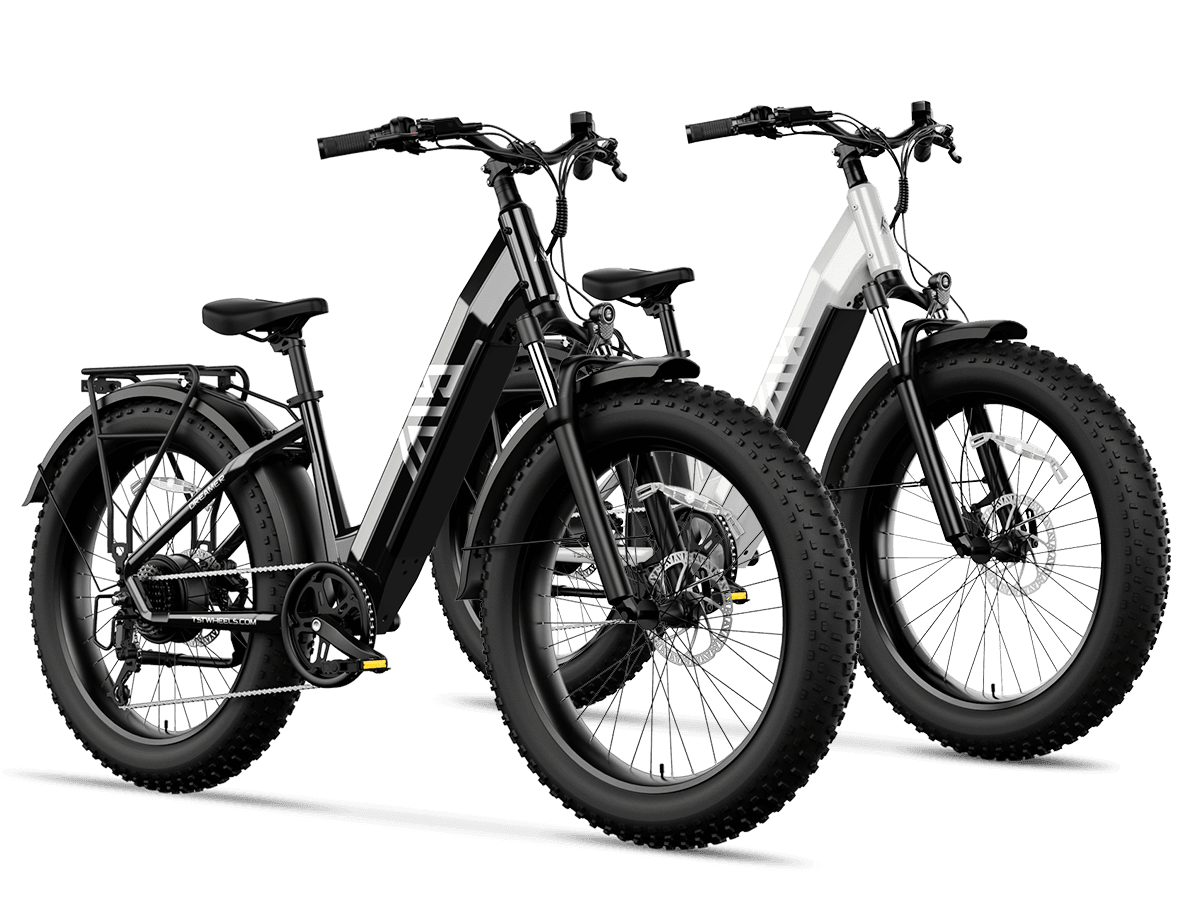

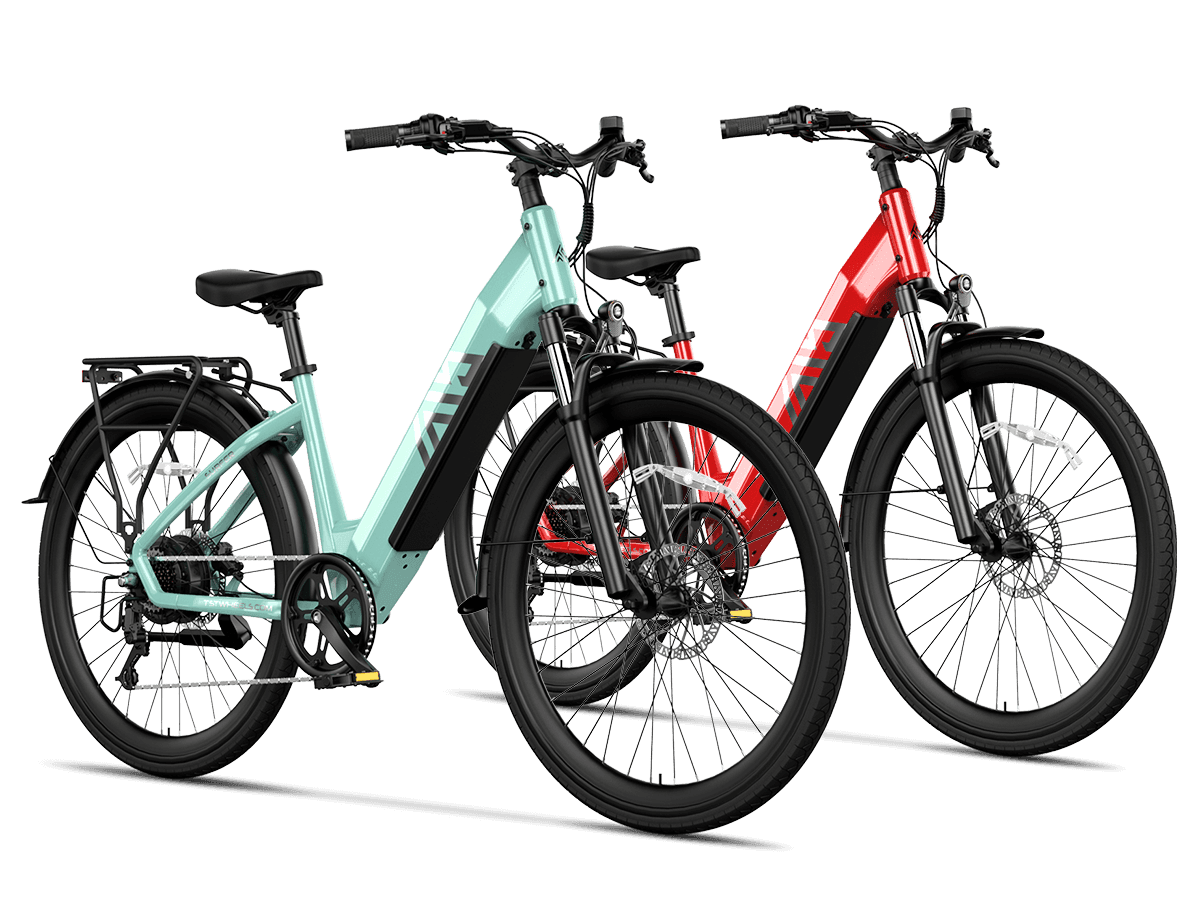

Which TST EBike models utilize this high-torque 1300W rear-drive setup?

TST EBike offers several models—particularly their fat-tire lines—that harness the high-torque 1300W rear-drive configuration:

- TST Dreamer (26″) – Features a 1300W motor with around 90 Nm torque, ideal for beach, snow, and off-road use.

- TST Defender (26″) – Equipped with a 1300W rear hub motor optimized for rugged terrain and steep climbs.

- TST high-speed fat tire models (Defender, R002) – Integrate 1300W brushless rear hub motors with 85-90 Nm torque, 48 V 15 Ah batteries, fat puncture-resistant tires, hydraulic brakes, and Shimano drivetrains for up to 65 miles and ~28 mph performance.

These models deliver the combined benefits of high-torque, rear-drive, and thoughtfully matched powertrain and components to provide powerful, versatile rides across diverse conditions.

Buying Tips

When selecting a high-torque 1300W rear-drive ebike, consider:

- Motor outputs (1300W, ≥ 85 Nm torque) for the aggressive performance you need.

- Battery capacity (48 V, 15 Ah or higher) to secure longer range and reliable power.

- Controller rating (≥ 20 A) for smooth power delivery under load.

- Tire choice: 26″ fat for off-road and rugged terrain, 27″ for commuting and mixed use.

- Safety features: hydraulic disc brakes and suitable suspension for control.

- Brand reliability: opt for reputable manufacturers like TST EBike known for quality and customer support.

- Compliance: ensure local regulations permit the motor’s power and speed capabilities.

TST EBike Expert Views

“At TST EBike, our mission is to redefine transportation by providing high-power, cost-effective electric bikes. Our 1300W rear-drive and high-torque models are engineered to tackle diverse terrains, offering riders both performance and reliability.”

“Our high-speed fat tire ebikes combine robust 1300W rear hub motors, long-lasting batteries, fat puncture-resistant tires, hydraulic brakes, and quality suspension—designed for up to 28 mph, 65-mile range, and safe, thrilling adventure.”

FAQ

Q: How fast can a high-torque 1300W rear-drive ebike go?

A: Typically around 28 mph, depending on terrain, rider weight, and local speed regulations.

Q: Is rear-drive better than mid-drive?

A: Rear-drive offers strong traction, simpler maintenance, and is usually more cost-effective; mid-drive excels in efficiency and torque at low speeds via gearing.

Q: Can I commute on this ebike daily?

A: Absolutely—especially if you need to handle hills, sand, snow, or carry cargo.

Q: How long does the 48 V 15 Ah battery last?

A: Generally 50–65 miles per charge, depending on assist level and terrain.

Q: What maintenance do rear hub motors need?

A: Minimal—mostly keep connections clean, ensure proper braking, and monitor battery health.

Q: What makes the tires puncture-resistant?

A: Deep treads and reinforced casing help reduce flats, enhancing durability across rough conditions.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.