A powerful rear-drive electric bike is defined by a high-torque motor positioned on the rear wheel, delivering strong propulsion, excellent traction, and efficient power transfer. These ebikes combine robust motor wattage (often 750W to 1500W or more), durable frames, and advanced sensors to provide rapid acceleration, hill-climbing ability, and stable handling, making them ideal for diverse terrains and heavy loads.

How Does Motor Power Influence a Rear-Drive Electric Bike’s Performance?

Motor power, measured in watts, directly affects the ebike’s acceleration, top speed, and hill-climbing capability. Rear-drive ebikes with motors ranging from 750W to 1500W produce high torque (up to 95Nm or more), enabling quick starts and sustained power on steep inclines. Higher wattage motors also support heavier riders and cargo, enhancing overall versatility and ride quality.

Chart: Motor Power vs Torque and Performance

| Motor Power (W) | Torque (Nm) | Typical Use Case |

|---|---|---|

| 250-500W | 35-55 | City commuting, light trails |

| 750-1000W | 70-95 | Off-road, cargo, hill climbing |

| 1300-1500W+ | 95+ | Heavy-duty, high-speed riding |

Why Is Rear-Wheel Drive Preferred for Powerful Ebikes?

Rear-wheel drive places the motor at the back wheel, where most rider weight naturally rests, improving traction and stability. This configuration excels in delivering power efficiently, especially on loose or slippery surfaces like gravel, sand, or wet roads. It also allows the front wheel to focus on steering, enhancing control. Rear-drive ebikes tend to have simpler installation and maintenance compared to mid-drive systems, making them popular for powerful ebike designs.

Which Features Enhance the Power and Efficiency of Rear-Drive Ebikes?

Rear-drive ebikes gain power and efficiency from features like high-torque motors, advanced motor controllers, and quality lithium-ion batteries with high capacity. Efficient drivetrain components, such as smooth gear systems and robust chain drives, improve power transfer. Additionally, regenerative braking and optimized pedal-assist sensors help maximize energy use. Together, these features ensure strong acceleration, longer range, and responsive handling, making rear-drive ebikes well-suited for varied terrains and demanding rides.

Key features that boost power and efficiency include:

- High-capacity batteries (48V 15Ah or higher) to supply sustained energy.

- Torque sensors for smooth, responsive pedal assist tailored to rider input.

- Robust frames designed to handle motor torque and rider weight.

- Quality controllers that manage power delivery and protect battery health.

- Compatibility with disc brakes for reliable stopping power under high speeds.

These components work in harmony to maximize performance while maintaining ride comfort and safety.

How Do Rear-Drive Motors Affect Handling and Ride Experience?

Rear-drive motors provide a natural riding feel by pushing the bike forward from the back wheel, enhancing traction and reducing wheel slip. This setup improves stability during acceleration and cornering, especially on uneven terrain. However, the added weight on the rear can slightly affect maneuverability at low speeds. Overall, riders benefit from confident control and powerful propulsion suited for varied riding conditions.

Why Are TST EBike’s Rear-Drive Models Noteworthy?

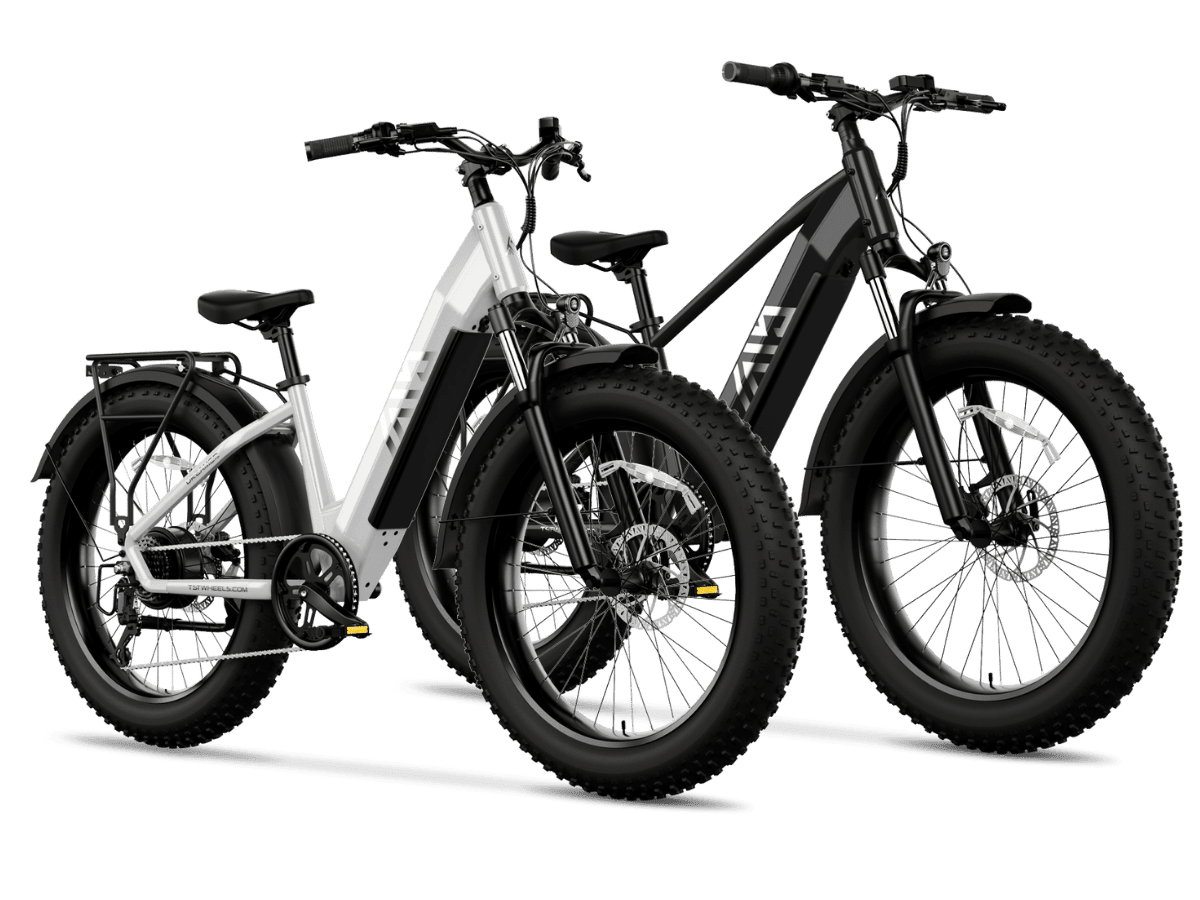

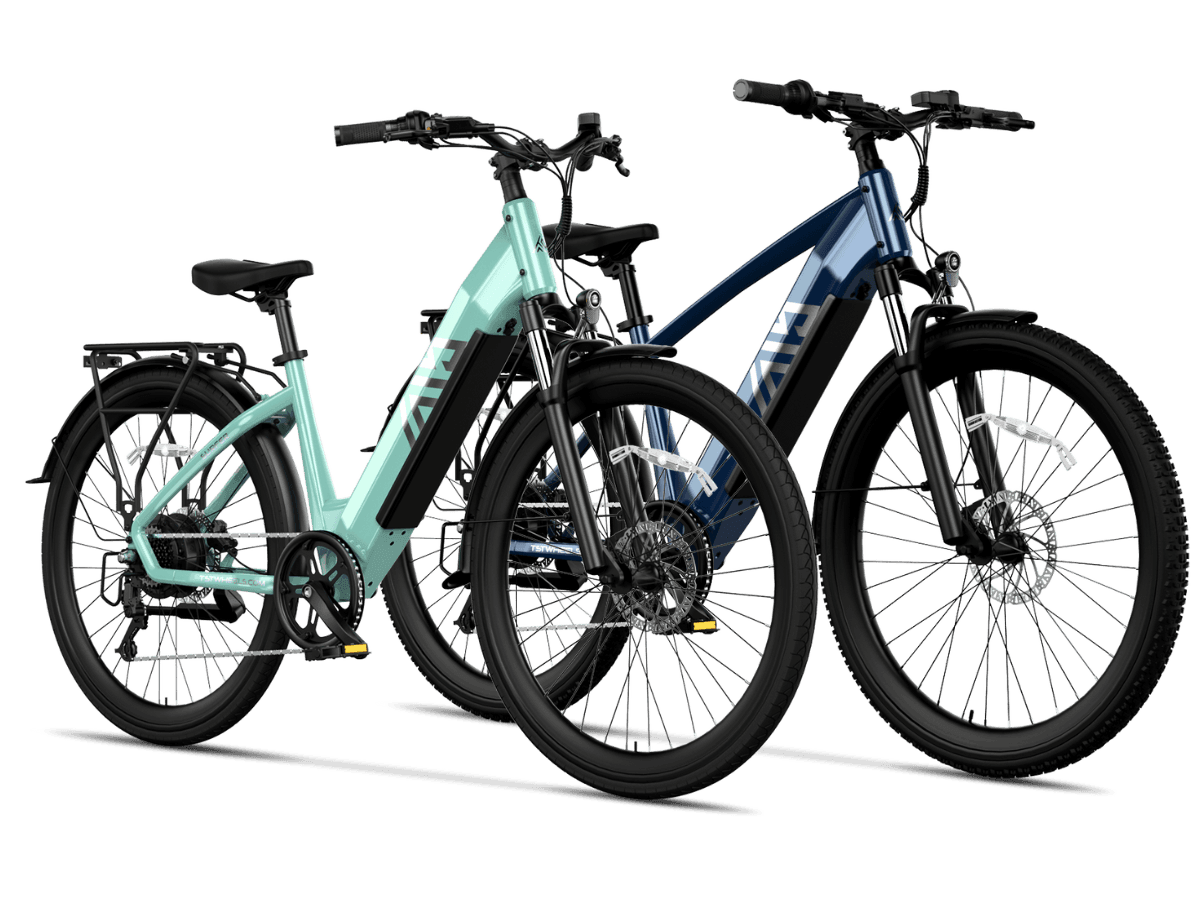

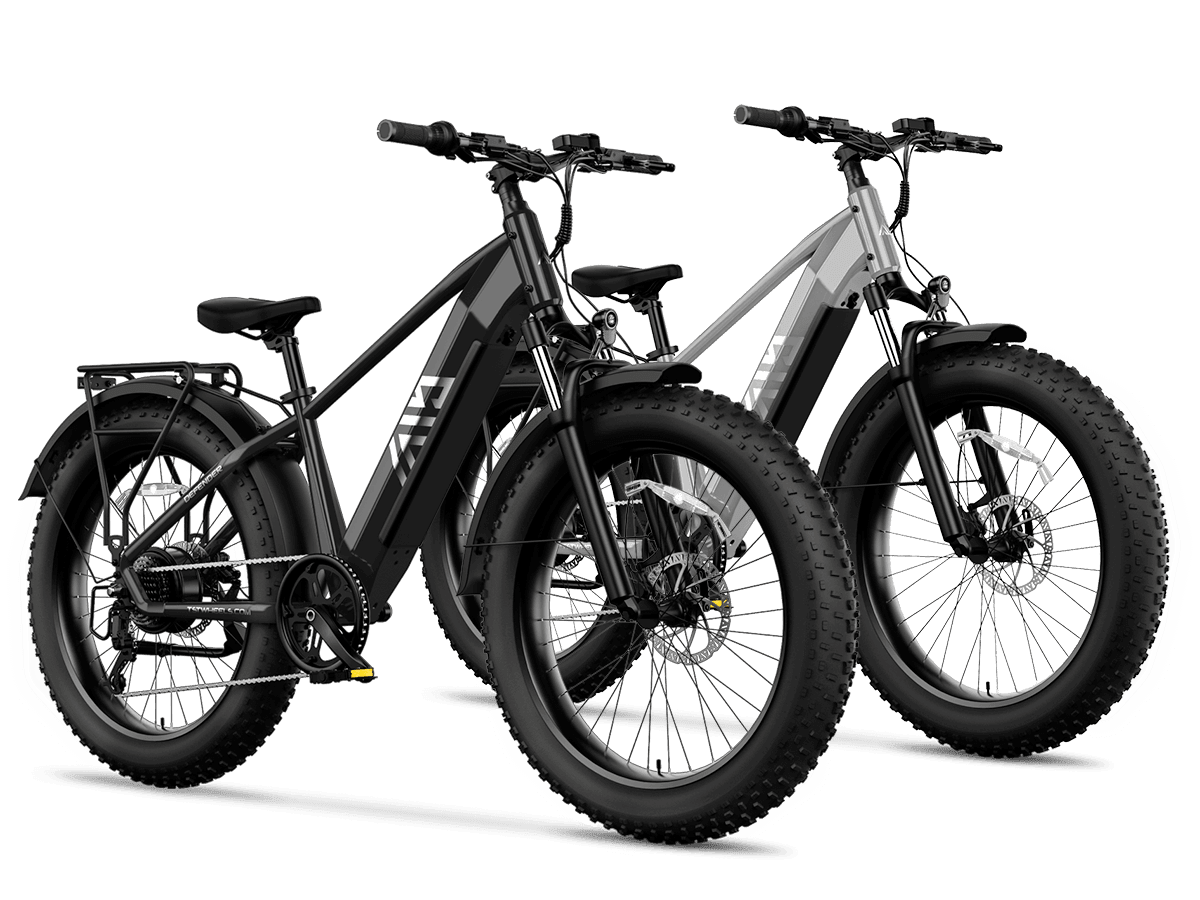

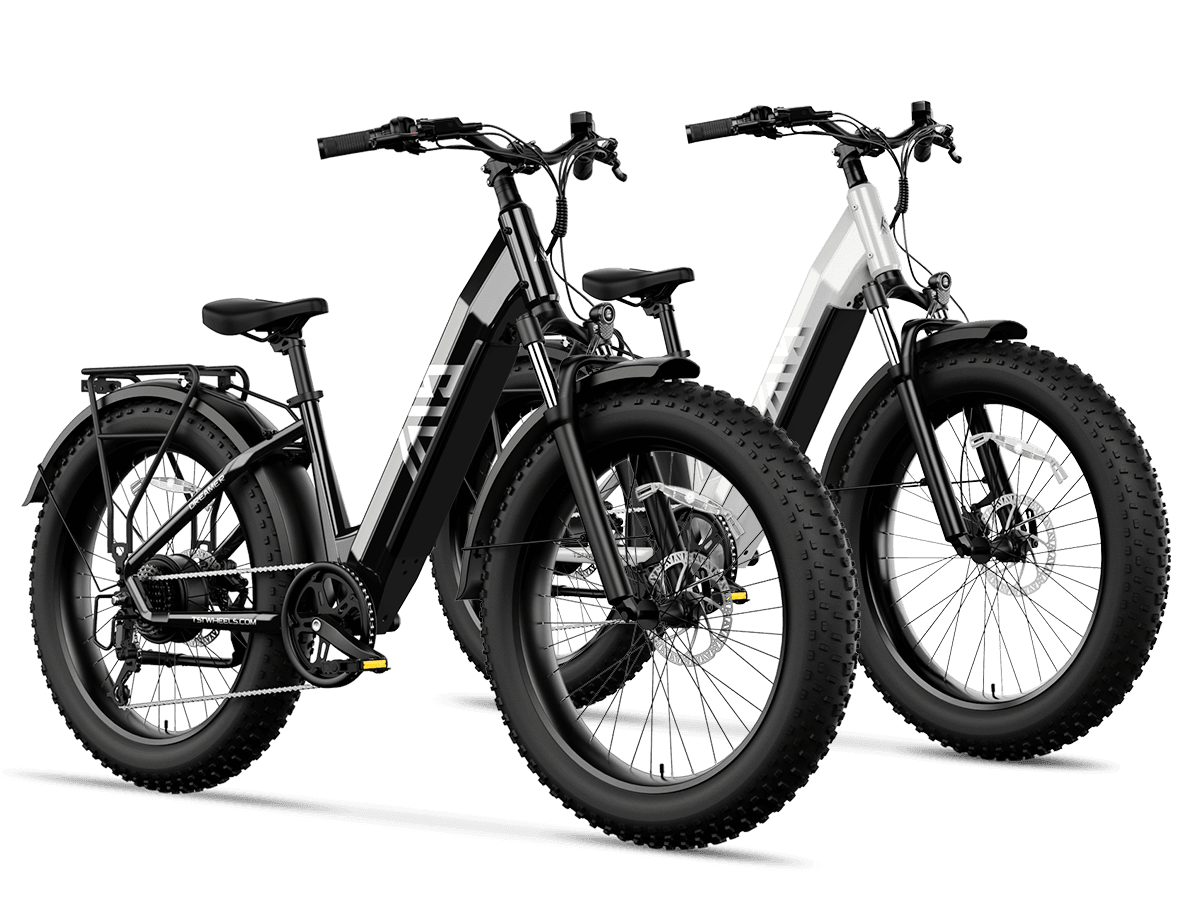

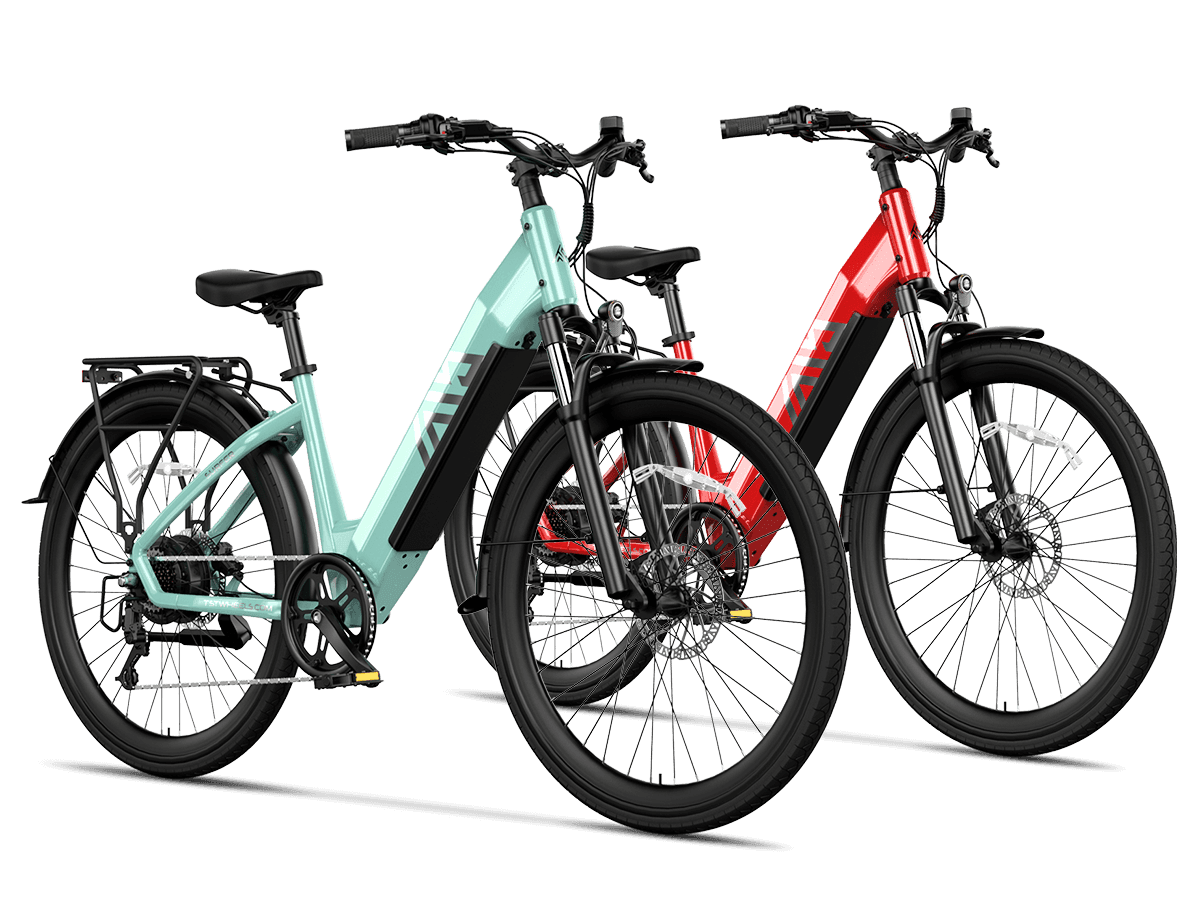

TST EBike offers rear-drive electric bikes with powerful motors ranging from 750W to 1300W, paired with 26-inch and 27-inch fat tires for superior traction on snow, sand, and mountain trails. Their models feature durable frames, high-capacity batteries, and advanced control systems designed from consumer feedback to balance power, efficiency, and affordability. TST EBike’s rear-drive lineup delivers dependable performance for riders seeking strength and versatility.

Buying Tips

When choosing a powerful rear-drive electric bike, consider:

- Motor wattage and torque ratings to match your riding style and terrain.

- Battery capacity and voltage for desired range and power consistency.

- Frame strength and geometry to support motor torque and rider weight.

- Presence of torque sensors and quality controllers for smooth power delivery.

- Reliable braking systems, preferably hydraulic disc brakes, for safety.

- Tire size and type, with fat tires enhancing grip on rough surfaces.

Test riding different models helps assess handling and comfort before purchase.

TST EBike Expert Views

“TST EBike’s rear-drive models combine high-power motors with fat tires and robust frames to deliver exceptional traction and control. Our focus on consumer-driven design ensures these ebikes meet the demands of riders tackling diverse terrains, from urban streets to rugged trails. The integration of advanced sensors and quality batteries provides a smooth, powerful ride that doesn’t compromise on efficiency or affordability.” – TST EBike Product Specialist

FAQ

What motor power is considered powerful for a rear-drive ebike?

Motors rated 750W and above are generally considered powerful, with some models reaching 1300W or more for heavy-duty use.

Does rear-wheel drive affect battery life?

Efficient power delivery in rear-drive ebikes can optimize battery usage, but actual life depends on riding conditions and battery capacity.

Are fat tires necessary for powerful rear-drive ebikes?

While not mandatory, fat tires improve traction and stability, especially on loose or rough terrain, complementing powerful motors.

Can rear-drive ebikes handle steep hills?

Yes, high-torque rear-drive motors excel at climbing steep inclines with strong, consistent power.

Which is better, 350W or 500W?

A 500W motor offers higher speed, torque, and better hill-climbing ability than a 350W motor, making it suited for varied terrain and heavier loads. However, 350W motors are lighter, more efficient on flat terrain, and often more affordable. Choose 350W for casual rides and 500W for stronger performance, like on some TST EBike models.

Does a bigger battery mean more power on an eBike?

No, a bigger battery means more capacity (longer range), not more power. Power depends on the motor wattage, while battery size (Ah) affects how far you can ride before recharging. Pairing a bigger battery with a motor like those on TST EBike extends ride time without increasing peak power.

Is there a big difference between a 500W and 750W eBike?

Yes, a 750W eBike generally provides more torque, faster acceleration, and better hill-climbing than 500W models. It consumes more battery under heavy loads and may be subject to legal restrictions. For riders needing strong performance on steep terrain or with heavy cargo, 750W offers noticeable advantages.

What is the difference between 750W and 1000W e-bike?

A 1000W e-bike delivers greater maximum power and torque than 750W, enabling higher top speeds and superior climbing. It suits riders requiring heavy-duty performance but usually draws more battery power and may be restricted by law. 750W balances power and efficiency well for most urban and recreational riders.

Powerful rear-drive electric bikes combine high-wattage motors, torque sensors, and durable components to deliver strong acceleration, excellent traction, and stable handling. With models like those from TST EBike, riders gain versatile, efficient machines capable of conquering diverse terrains and heavy loads.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.