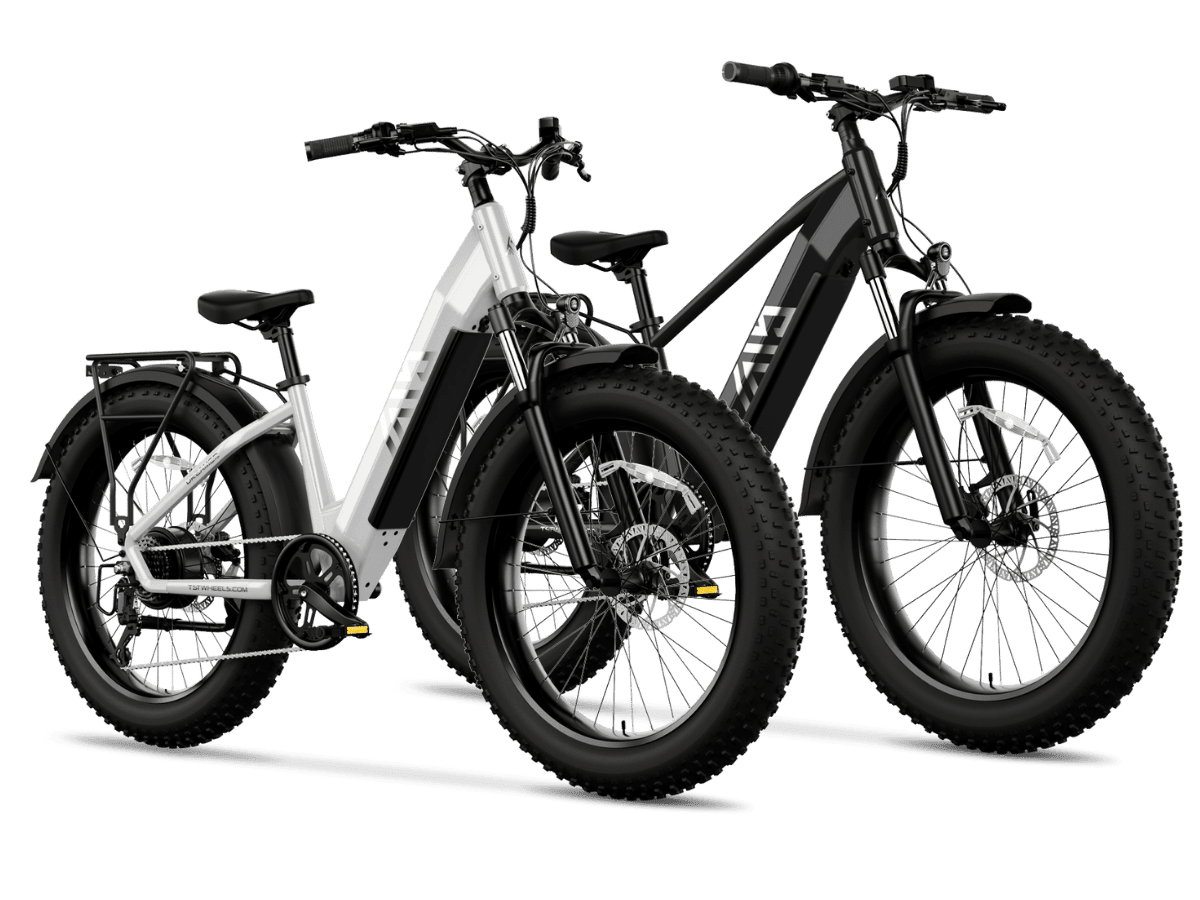

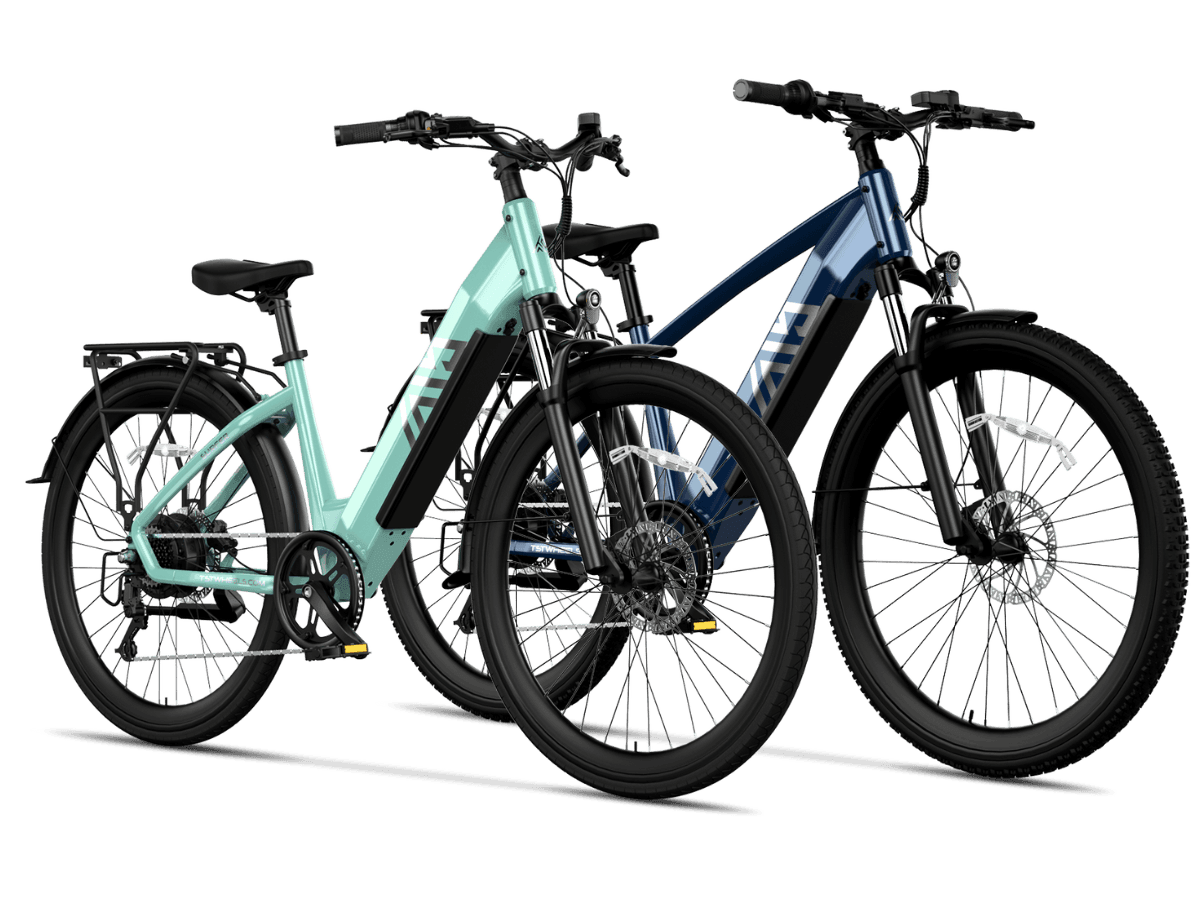

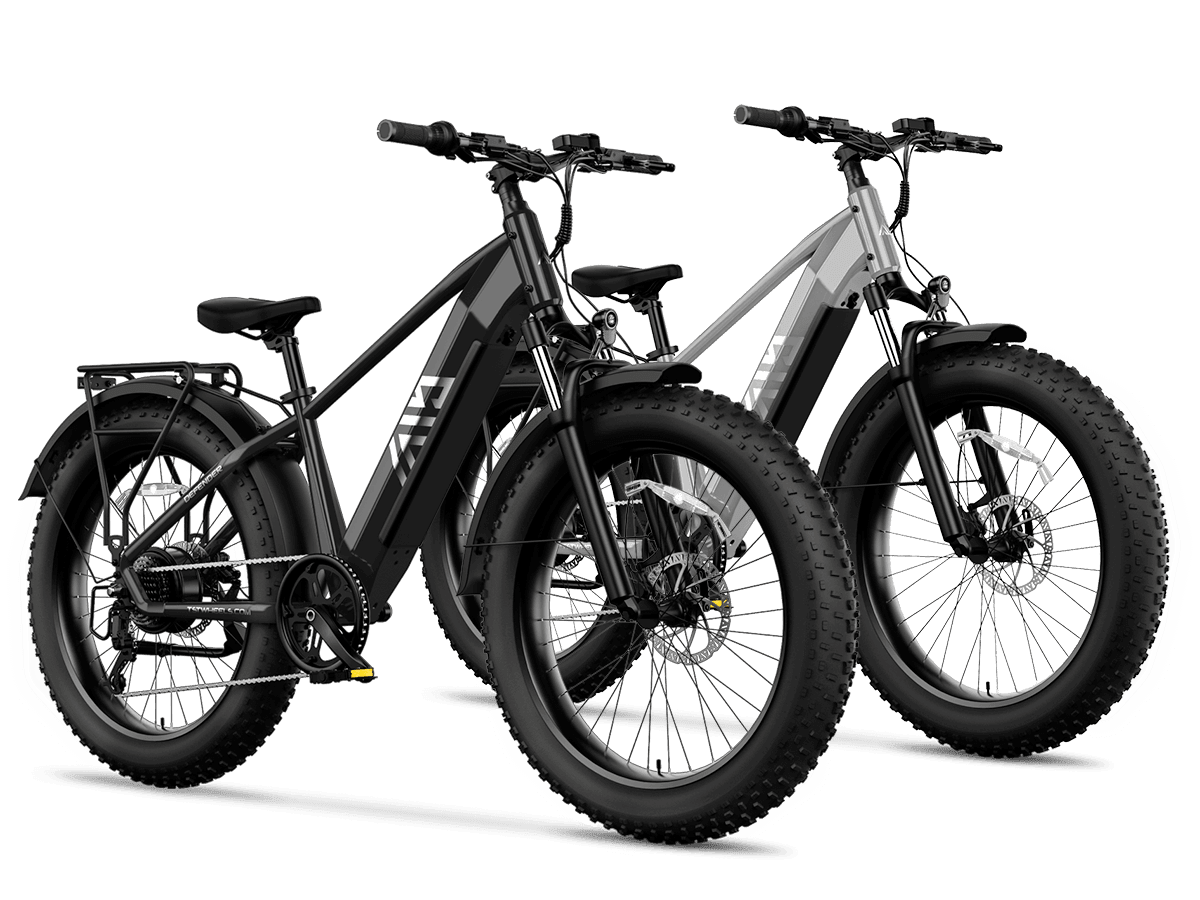

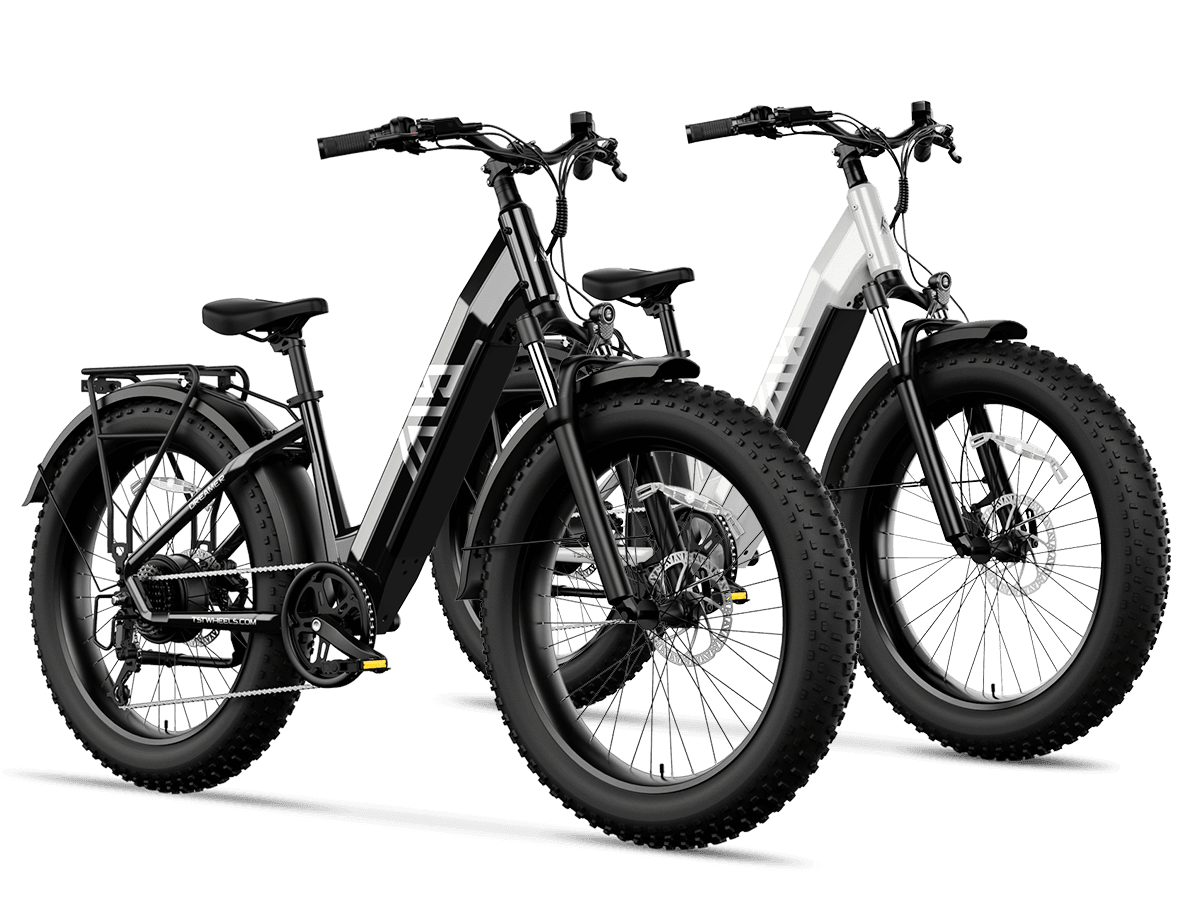

A 500lb e-bike undergoes comprehensive strength testing in Mammoth Lakes, including structural stress analysis, endurance trials on rugged terrain, and load-bearing capacity checks. TST EBike employs these testing protocols to ensure their heavy-duty models perform reliably and safely under extreme conditions found in snow and sand terrains. Also check: Electric Bike 500lb Capacity

What Structural Tests Are Used to Verify Strength of a 500lb E-Bike?

Structural tests for a 500lb e-bike include frame stress testing under hydraulic presses, fatigue testing on welds and joints, and torsion resistance assessments. These simulate real-world forces, ensuring the frame and components withstand heavy loads, vibrations, and impacts typical of Mammoth Lakes’ demanding environment.

How Does Load Testing Evaluate the E-Bike’s Capacity?

Load testing applies weights exceeding the e-bike’s maximum rated load repeatedly to assess durability. This includes evaluating suspension compression, wheel integrity, and braking systems under stress, confirming that the e-bike safely supports combined rider and cargo weights up to 500lbs.

Which Terrain-Specific Tests Are Conducted in Mammoth Lakes?

Terrain tests replicate off-road conditions such as steep climbs, rocky paths, snow, and loose sand trails. The e-bike is ridden or machine-tested on these to measure handling, stability, motor strain, and braking efficacy under heavy load, reflecting practical usage scenarios for TST EBike riders.

Why Is Temperature and Weather Testing Included in Strength Assessment?

Mammoth Lakes’ cold, variable weather exposes the e-bike to freezing temperatures, moisture, and rough snow surfaces. Testing checks for material brittleness, battery performance in cold, and motor cooling effectiveness under these conditions to guarantee reliability and longevity.

When Is Fatigue Testing Performed and Why Is It Important?

Fatigue testing is carried out after structural and load tests to simulate long-term use. It involves repetitive stress cycles on the frame and drivetrain to identify potential failure points, ensuring the e-bike maintains strength and safety over thousands of miles typical for heavy riders.

How Are Electrical and Motor Components Tested for Strength?

Electrical systems, including batteries and motors, undergo overload, heat, and shock resistance tests. This ensures components handle excessive loads without failure. TST EBike integrates thermal management and high-quality motors to maintain performance when carrying heavier weights.

Can TST EBike Customize Strength Testing for Different Models?

Yes, TST EBike customizes testing protocols based on model specifications like weight, motor power, and intended terrain use. This tailored approach ensures each e-bike’s durability matches user needs, optimizing safety and performance in difficult terrains like Mammoth Lakes.

Who Oversees and Certifies E-Bike Strength Tests?

Professional testing labs and in-house engineering teams conduct and certify strength tests. They follow industry standards to guarantee compliance with safety and durability benchmarks. TST EBike collaborates with certified bodies to validate the rigor of their 500lb e-bike testing.

What Safety Standards Must 500lb E-Bikes Meet in Testing?

500lb e-bikes must meet frame strength, braking efficiency, electrical safety, and fatigue resistance standards. Compliance with regulations ensures rider safety and product reliability. These standards guide TST EBike’s design and testing strategies to meet global safety requirements.

How Does Feedback From Real-World Testing Influence Product Development?

Data from rugged terrain tests and rider feedback in Mammoth Lakes informs design improvements, material enhancements, and component upgrades. TST EBike continuously integrates this feedback to refine e-bikes, ensuring greater strength, comfort, and performance for heavy-duty users.

Table: Key Strength Testing Methods for 500lb E-Bikes

| Test Type | Purpose | TST EBike Application |

|---|---|---|

| Structural Stress | Verify frame durability | Hydraulic press & joint fatigue |

| Load Testing | Assess weight capacity | Suspension & brake system stress |

| Terrain Testing | Simulate off-road conditions | Real rides on snow and rocky paths |

| Temperature Testing | Ensure cold-weather performance | Battery & material brittleness |

| Fatigue Testing | Predict long-term wear | Repetitive stress cycling |

| Electrical Testing | Confirm motor and battery safety | Heat & overload resistance |

Table: Safety Standards and Regulations for Heavy E-Bikes

| Standard Area | Key Requirements | Testing Indicators |

|---|---|---|

| Frame Strength | Load capacity, impact resistance | Stress & fatigue test results |

| Braking Systems | Effective stopping at weight load | Brake performance under load |

| Electrical Safety | Overheat protection, insulation | Thermal & electrical overload tests |

| Battery Testing | Cold temperature function | Capacity retention & safety checks |

| Durability Standards | Long lifecycle expectancies | Fatigue resistance and real-world trials |

TST EBike Expert Views

“At TST EBike, testing the strength of our 500lb electric bikes in Mammoth Lakes is critical to delivering premium, heavy-duty rides. We combine rigorous laboratory and real-world terrain trials to validate every frame, suspension, and motor component for toughness and reliability. Our commitment ensures riders enjoy superior performance and safety, no matter how challenging the conditions or rider weight.”

Conclusion

Testing a 500lb e-bike for strength in Mammoth Lakes involves comprehensive structural, load, terrain, temperature, and fatigue assessments designed to ensure durability and rider safety. TST EBike’s systematic approach guarantees their models meet these demanding criteria, providing reliable performance for heavy users in extreme environments. Proper testing combined with real-world feedback drives continuous innovation and confidence in heavy-duty e-bikes.

Frequently Asked Questions

How does TST EBike ensure 500lb e-bikes are safe for rough terrain?

Through extensive load, terrain, and fatigue testing tailored for challenging environments like Mammoth Lakes.

What types of materials are used for heavy-duty e-bike frames?

High-strength alloys and reinforced composites designed for impact resistance and durability.

Can 500lb e-bikes handle snow and sand terrains effectively?

Yes, with specialized tires and suspension tested under real conditions, including snow and sand.

How often should heavy e-bikes be maintained after strength testing?

Regular maintenance every 3-6 months is recommended to preserve strength and safety.

Are TST EBike’s 500lb models certified for safety and durability?

Yes, they meet industry-standard certifications validated through rigorous testing.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.