Cargo bikes are costly primarily due to their specialized design, reinforced materials to carry heavy loads, powerful electric motors and batteries, and advanced safety and comfort features. The integration of durable components and engineering for longevity and performance, combined with limited mass production, drives the higher price compared to standard bicycles.

What Design and Material Factors Contribute to Cargo Bike Costs?

Cargo bikes feature extended frames, reinforced components like heavy-duty chains, forks, and rear triangles, and larger load-bearing areas to support significant weights often exceeding 200 lbs. High-quality aluminum or steel alloys, sometimes blended with carbon fiber, bolster strength and reliability but increase manufacturing complexity and cost. Custom cargo bike frames often require more labor-intensive assembly and design validation, pushing prices up compared to simpler frames.

How Do Motor and Battery Choices Affect Cargo Bike Prices?

Electric cargo bikes require more powerful motors, typically between 500W and 1000W, to move heavier loads effectively, along with larger capacity batteries (48V 14Ah or more) providing extended range under load. These premium components are costlier than those on commuter or recreational e-bikes. Battery management systems, power controllers, and robust wiring also add to the cost, ensuring the bike can handle sustained heavy use safely and efficiently.

Chart: Motor and Battery Impact on Price

| Component | Cost Influence Description |

|---|---|

| Motor Power (500W-1000W) | Higher power increases component and integration costs |

| Battery Capacity (48V 14Ah+) | Larger, long-lasting batteries are expensive and complex |

| Control Systems | Advanced controllers for heavy loads add cost |

Why Are Cargo Bikes Equipped with Advanced Safety and Comfort Features?

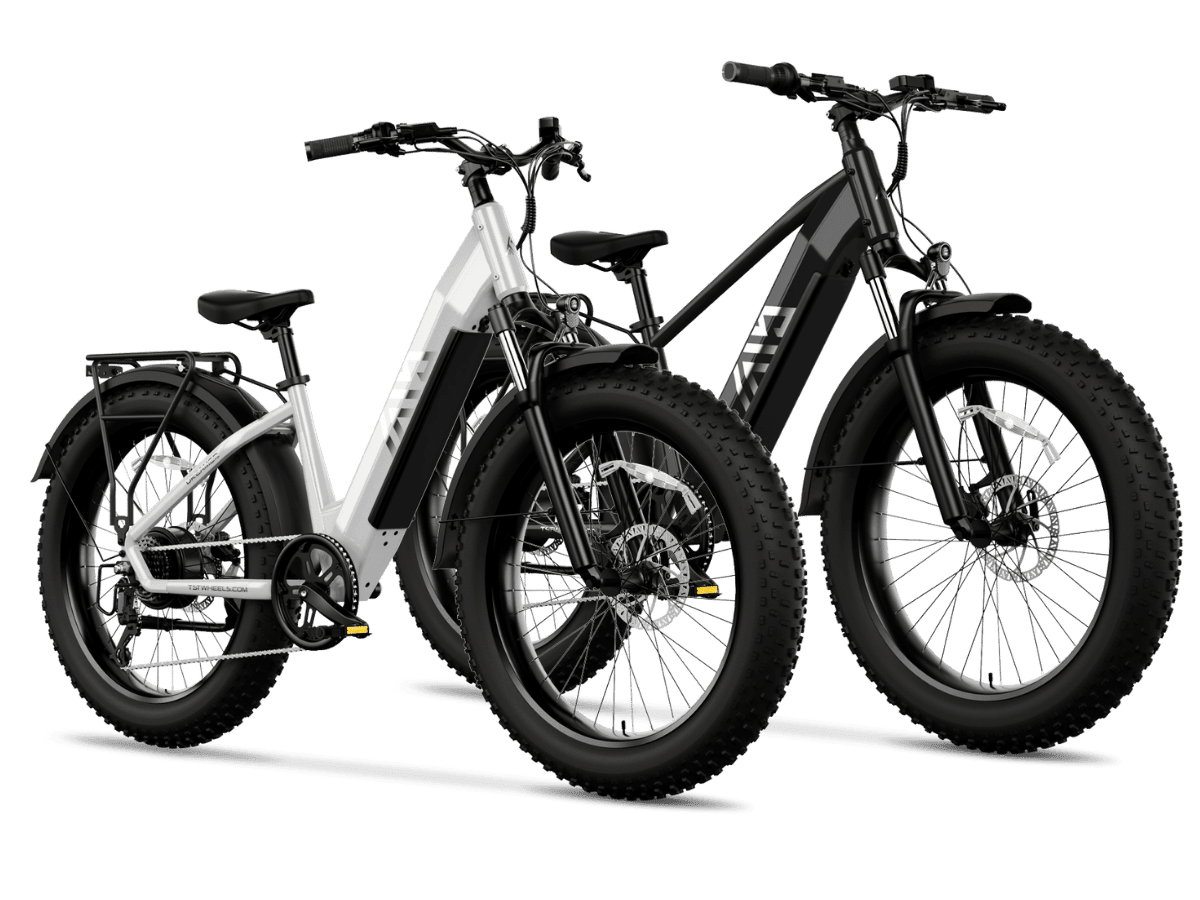

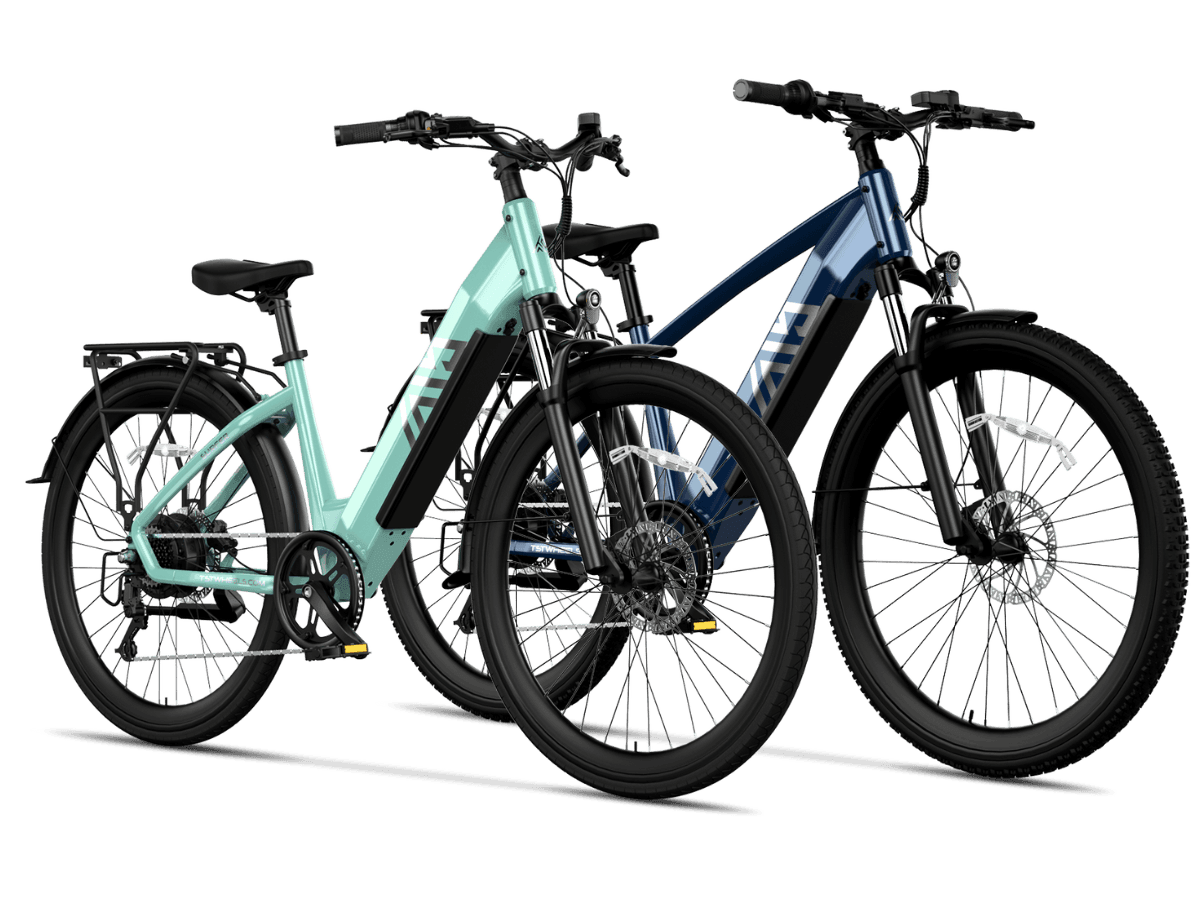

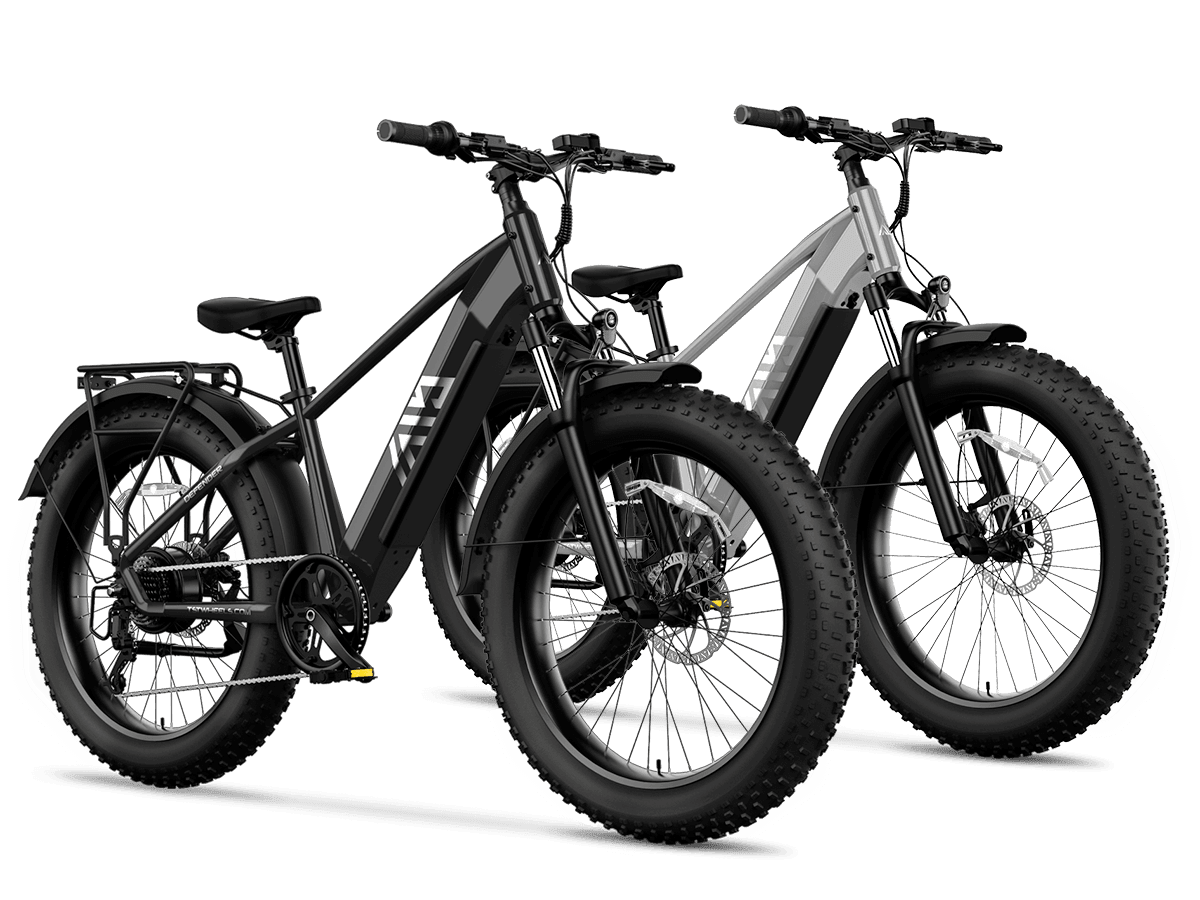

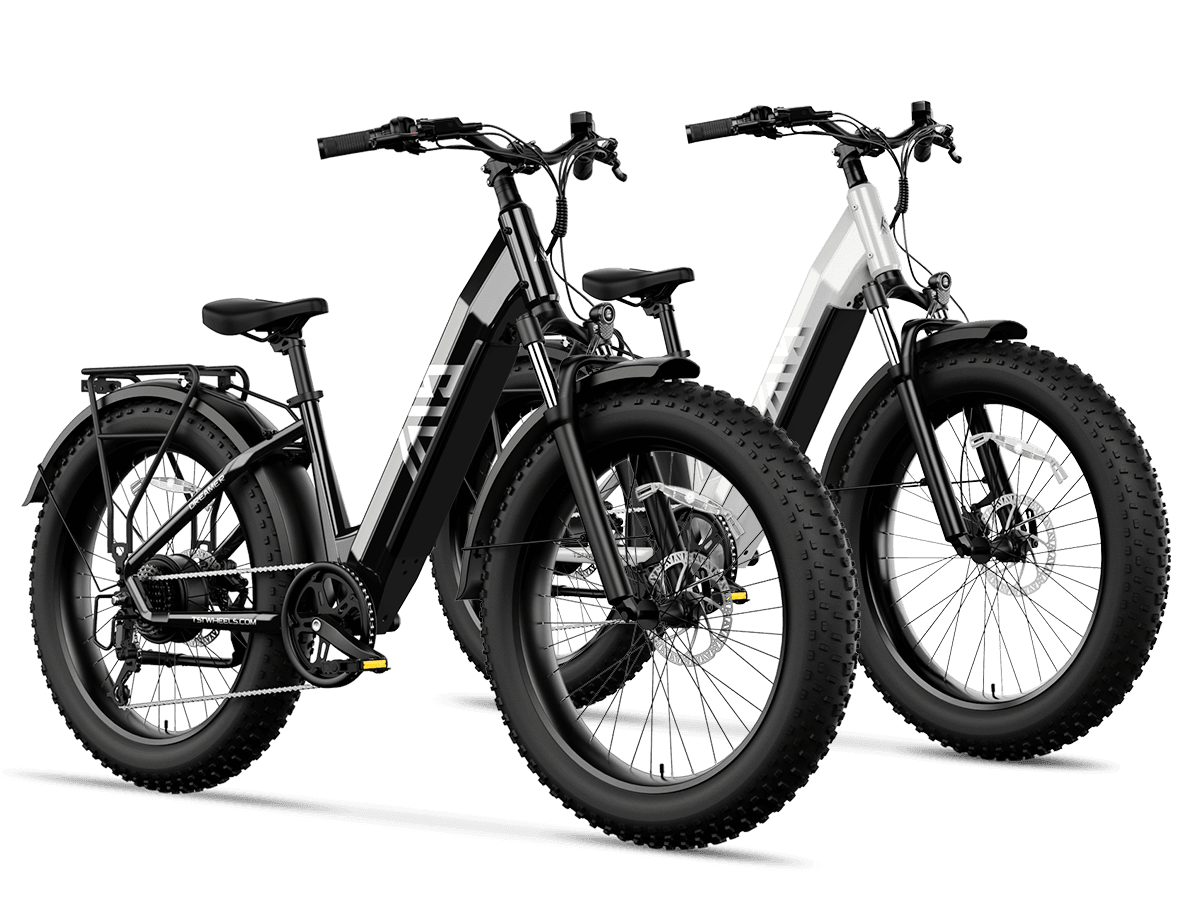

Due to heavier loads and potential passengers, cargo bikes incorporate hydraulic disc brakes, reinforced suspensions, wide tires for grip, and ergonomic seating to guarantee safety and user comfort. Extras like integrated lights, cargo racks, and weather protection accessories increase material and assembly costs. These features are essential given the unique demands of cargo bikes but inevitably raise the retail price.

How Does Limited Production Influence Cargo Bike Pricing?

Cargo bikes are niche products produced in smaller quantities compared to standard or folding bikes. This low-volume production reduces economies of scale, causing unit costs for design, tooling, and parts to remain high. Additionally, high-quality cargo bike components often come from specialized suppliers, adding to procurement expenses. As demand grows, prices may moderate, but currently, exclusivity and craftsmanship contribute to the higher price points.

What Are the Long-Term Value and Cost-Benefit Considerations of Cargo Bikes?

Though initially expensive, cargo bikes represent a long-term investment in durable, versatile, and eco-friendly transport, potentially replacing cars for short urban trips. Save on gas, parking fees, and maintenance while obtaining a product designed for longevity. Their ability to haul heavy loads efficiently and safely offers practical value unmatched by most traditional bicycles or scooters.

Buying Tips

When purchasing a cargo bike, consider:

- The typical load weight and volume you expect to carry to choose sufficient frame strength and motor power.

- Battery range relative to your commute or route needs, balancing capacity and weight for ergonomics.

- Safety features like hydraulic disc brakes and quality suspension to ensure rider confidence.

- Brand reputation and after-sales support, with trusted companies like TST EBike focused on quality and consumer feedback.

- Test riding different models to assess comfort, handling, and usability.

- Storage and parking needs given cargo bike size and weight.

A strategic purchase balances cost against durable, safe, and practical ride experiences.

TST EBike Expert Views

“TST EBike acknowledges that cargo bikes’ higher costs are intertwined with their engineering to deliver strength, safety, and superior freight capabilities,” explains a TST EBike design lead. “Our focus is on optimizing technologies to provide cost-effective, powerful bikes that adapt to real-world demands. Investing in quality components and consumer-driven design enables riders to embrace sustainable urban logistics confidently and comfortably.”

FAQ

Q1: Why do cargo bikes cost more than regular bikes?

Their specialized frames, powerful motors, high-capacity batteries, and advanced safety features increase manufacturing costs.

Q2: Are electric cargo bikes more expensive than non-electric ones?

Yes, the motor and battery systems add significantly to the price compared to manual cargo bikes.

Q3: Do cargo bikes require special maintenance?

Maintenance is similar to standard bikes but may include additional care for heavier loads and electrical components.

Q4: How long do cargo bike batteries last on average?

With typical use, batteries last several years, charging for 40-80 miles per cycle depending on capacity.

Q5: Can cargo bikes replace cars for daily errands?

For many urban users, cargo bikes offer a practical, sustainable alternative for short-distance transport and hauling.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.