Cargo ebikes are expensive primarily due to their reinforced frames, powerful motors, and large-capacity batteries designed to handle heavy loads without compromising performance or safety. The incorporation of durable materials, advanced safety features, and specialized cargo components elevates manufacturing costs. TST EBike’s 26-inch and 27-inch models exemplify the balance between high capacity and cost-effective design, catering to varying terrain and user demands.

What Are the Key Reasons Cargo Ebikes Are More Expensive?

Cargo ebikes require stronger structural components to support heavy loads, larger and more powerful batteries to accommodate increased energy demands, and advanced motors capable of sustained torque. They often include enhanced safety features and longer-lasting parts to endure frequent, weighty use. These factors combined with design complexity and market demand contribute to elevated prices.

How Do Frame Design and Materials Impact the Price of Cargo Ebikes?

The frame of a cargo ebike is typically extended and reinforced using high-grade aluminum or steel to bear significant weight and maintain ride stability. The materials and engineering needed for strength and durability increase production costs substantially compared to standard ebikes with lighter, simpler frames.

Frame Design Cost Impact Chart

| Frame Component | Cost Factor | Reason |

|---|---|---|

| Reinforced Frame | High | To support heavy cargo and rider |

| Extended Wheelbase | Moderate | Enhances stability for loads |

| Material Quality | Varies (Aluminum/Steel) | Impacts durability and weight |

Why Do Powerful Motors and Larger Batteries Increase Cargo Ebike Costs?

Cargo ebikes require motors typically rated at 750W or more to provide sufficient torque to move heavy weights comfortably. Larger batteries, often exceeding 600Wh capacity, are necessary to maintain range despite high power consumption. Both motor and battery components are among the most expensive parts in any e-bike, driving up the overall price of cargo models.

How Do Safety Features and Durability Requirements Affect Pricing?

Due to heavier payloads, cargo ebikes demand premium braking systems, commonly hydraulic disc brakes, that offer reliable stopping power under load. Suspension systems and durable tires are essential for safety and comfort, adding to component complexity and cost. Quality control and safety certification also increase manufacturing expenses but assure rider protection and long-term reliability.

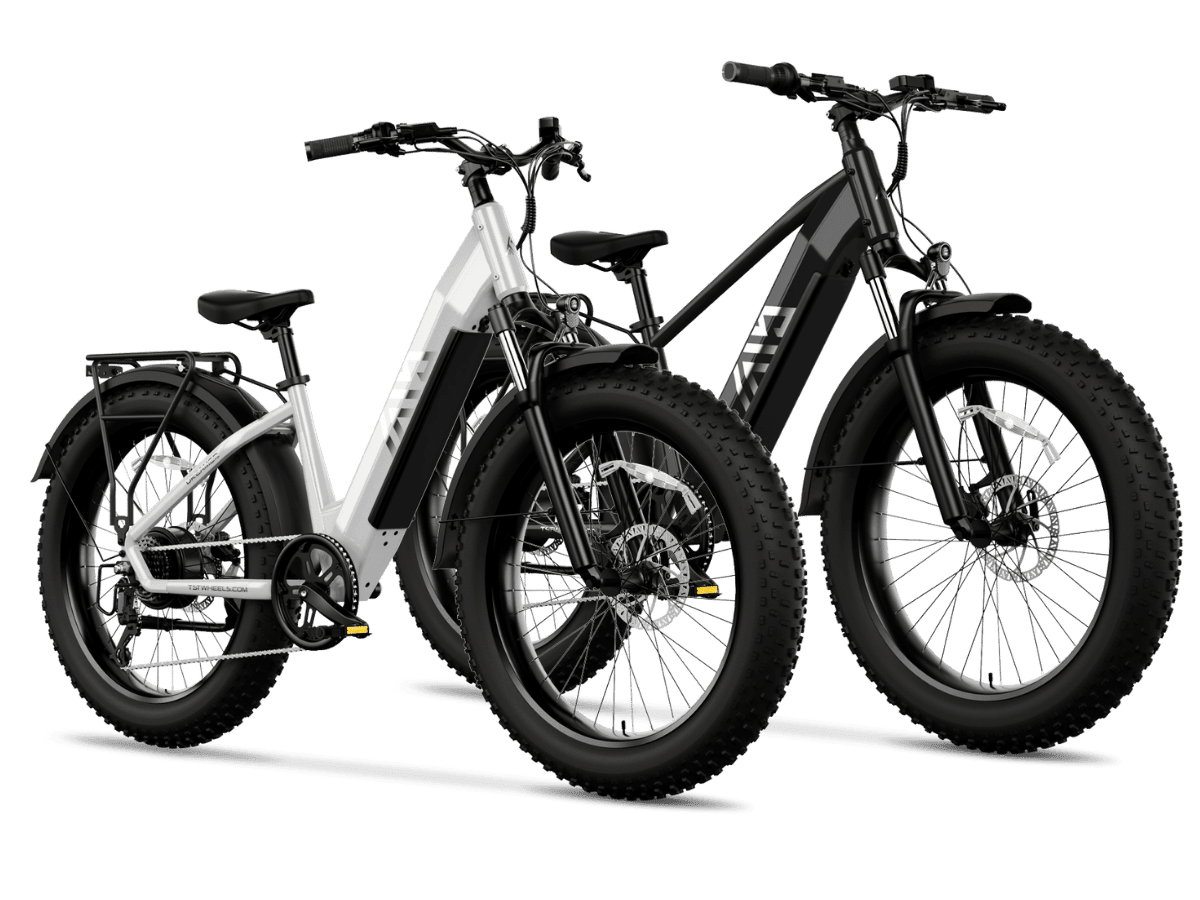

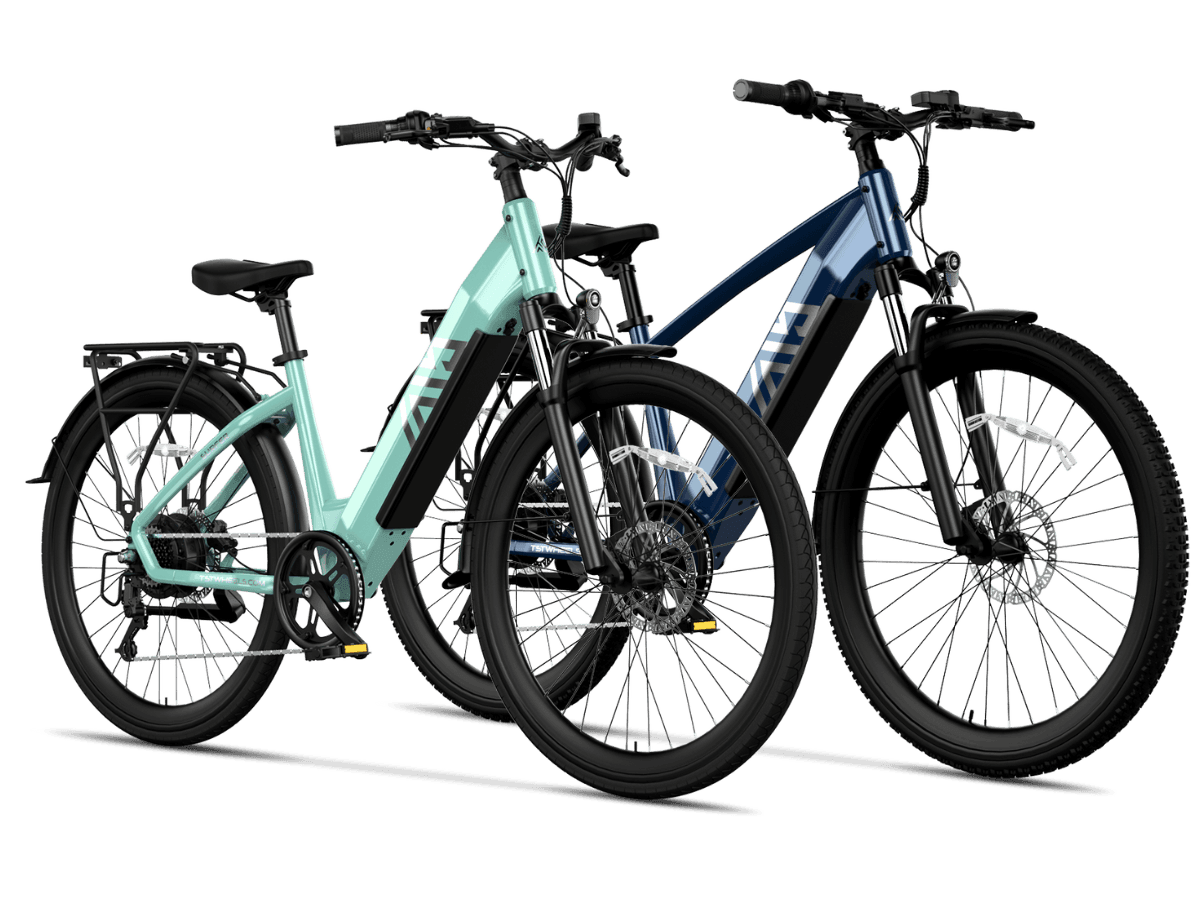

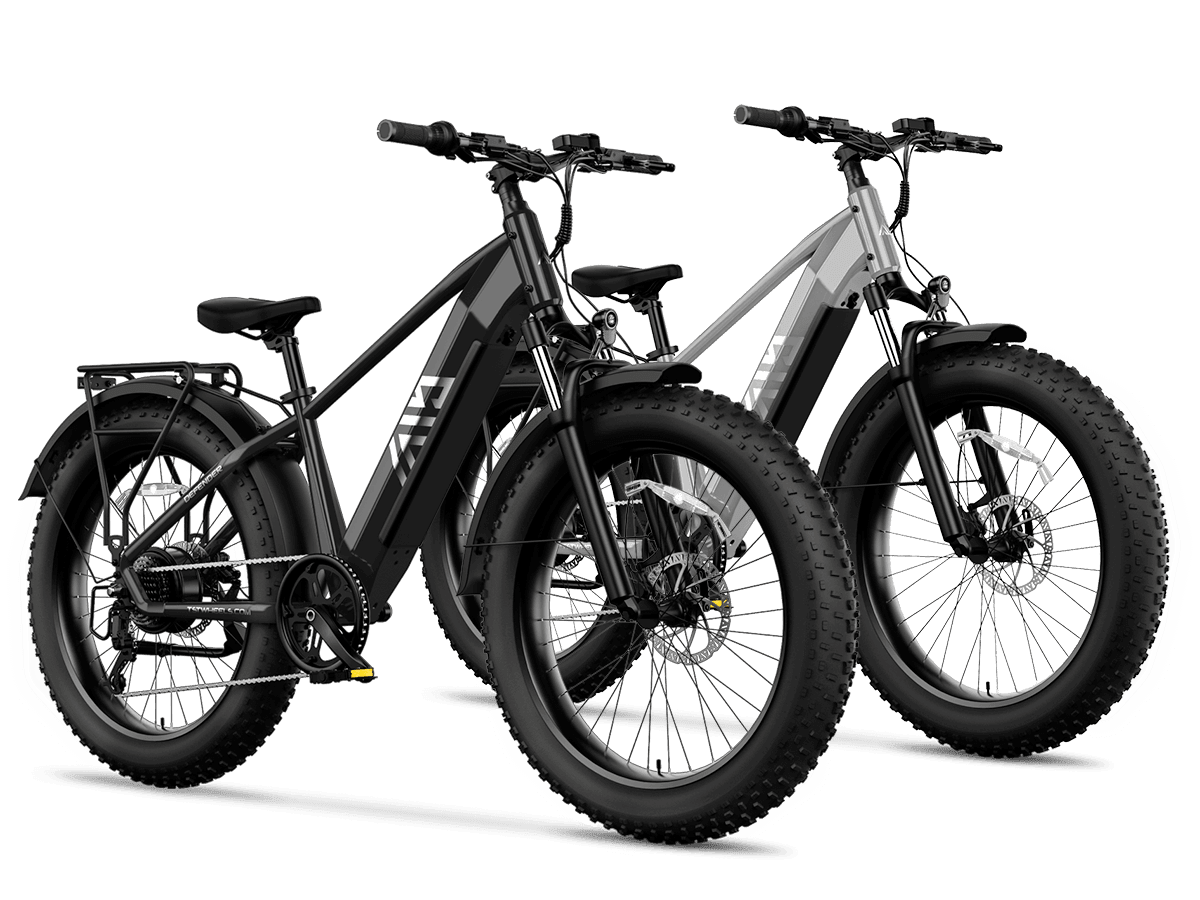

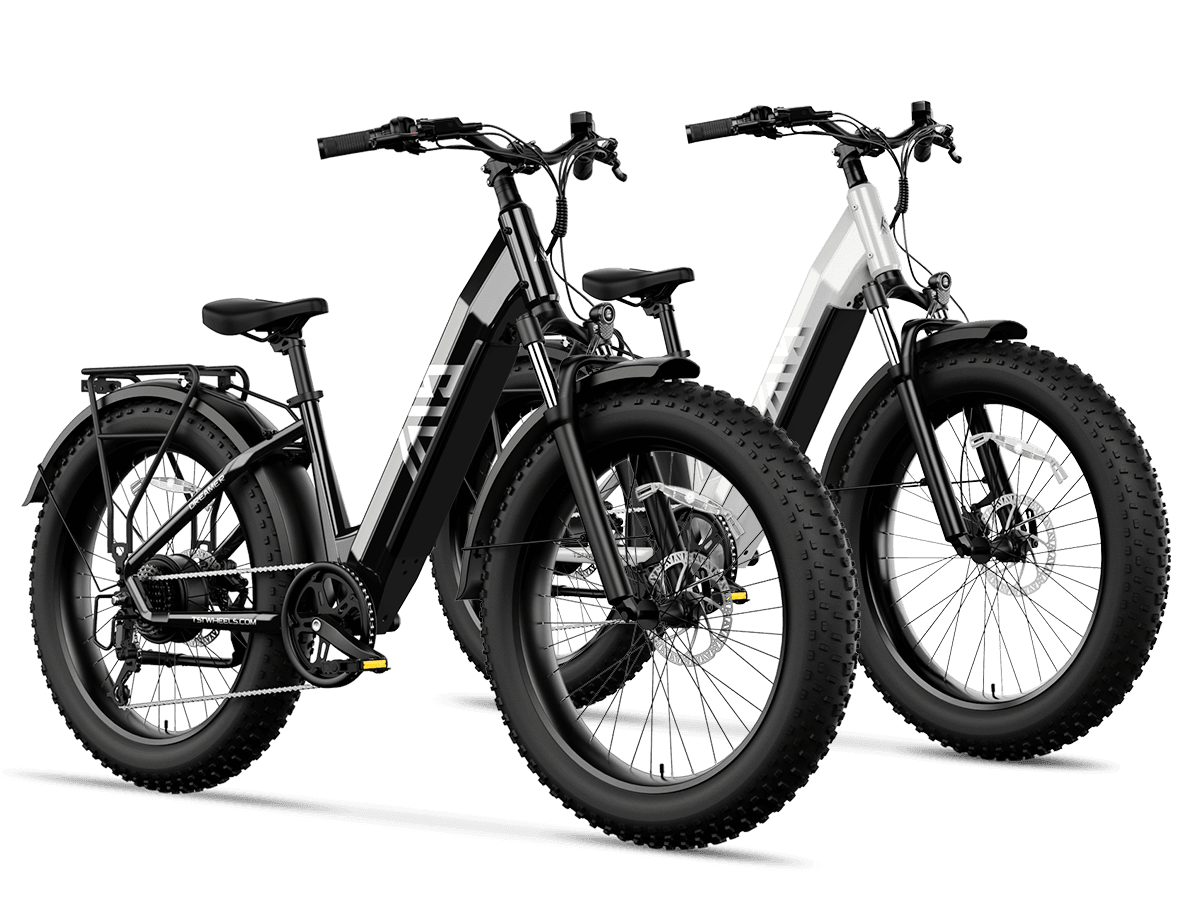

Which TST EBike Models Provide Quality Cargo Carrying at Competitive Prices?

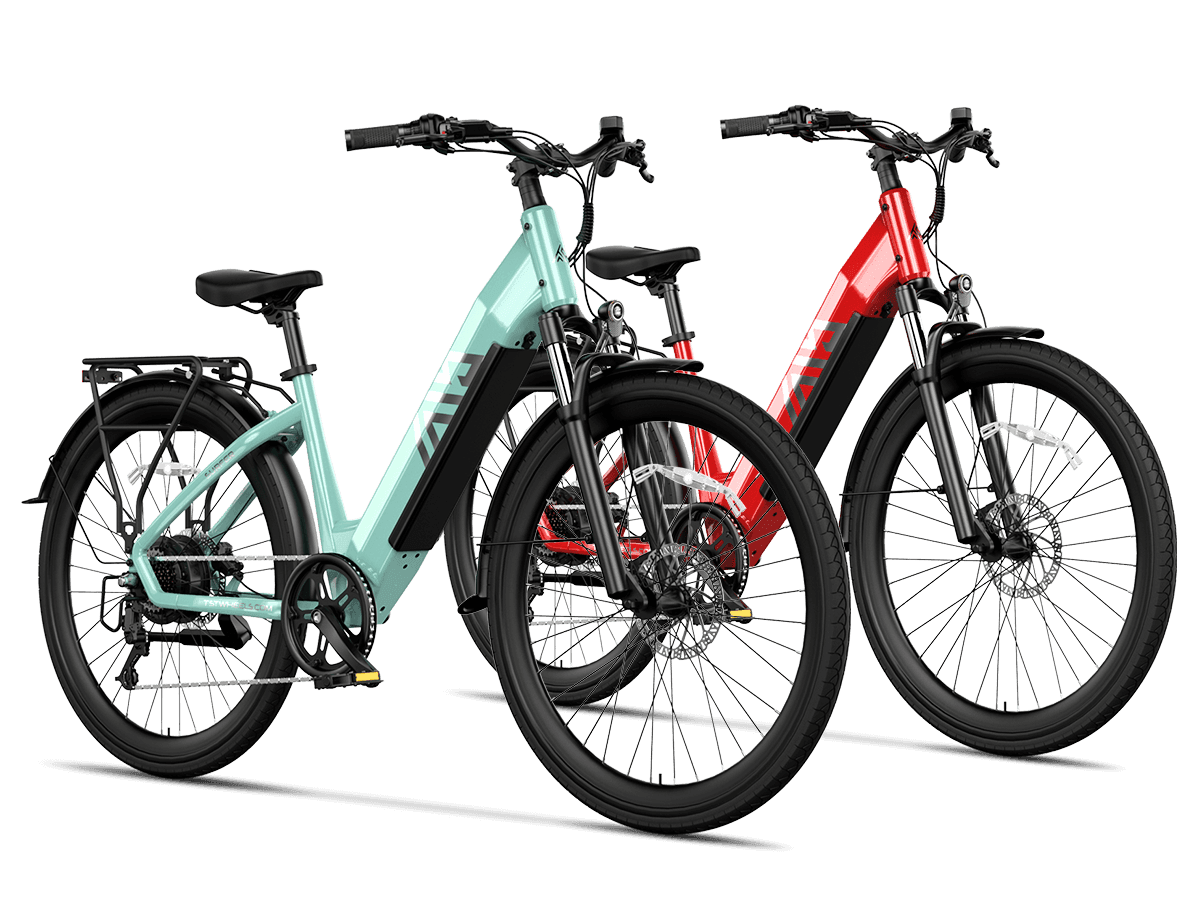

TST EBike offers 26-inch and 27-inch models optimized for different cargo uses. The 26-inch model provides robust performance on demanding terrains like snow and sand, while the 27-inch balances efficient daily commuting with cargo capability. Both models incorporate powertrains and frames designed to carry substantial loads with cost-effective manufacturing that prioritizes durability and customer feedback.

How Do Specialized Cargo Components Affect Overall Cost?

Cargo ebikes include unique features such as reinforced cargo racks, extended seats, heavy-duty kickstands, and modular cargo boxes that enhance utility but add weight and manufacturing expenses. Integration of load sensors, electric assist tuning for cargo, and enhanced wiring for accessories further contribute to cost increases compared to standard ebikes.

What Should Consumers Know When Considering the Price of Cargo Ebikes?

Potential buyers should understand that the premium reflects the engineering required for high capacity, safety, and durability. Assess whether your cargo needs warrant the investment and compare models on motor power, battery range, and frame strength. Evaluating total cost of ownership including maintenance ensures informed decisions. Brands like TST EBike offer transparent pricing for a balance of value and performance.

Buying Tips

When purchasing cargo ebikes, prioritize motor wattage (750W+) for understandable power reserves, large battery capacity (600Wh+) for extended range, and sturdiness in frame materials. Look for hydraulic braking systems and durable tires to ensure safety. Consider the compatibility of cargo accessories and the reputation of brands like TST EBike known for durable, cost-conscious designs suited to varied terrains.

TST EBike Expert Views on Cargo Ebike Pricing

“At TST EBike, we recognize that cargo ebikes’ elevated prices stem from the necessity of robust materials, powerful electric components, and enhanced safety features to meet the demands of carrying heavy loads reliably. Our 26-inch and 27-inch designs focus on delivering uncompromised strength and performance while keeping costs feasible, ensuring accessibility to consumers needing practical and durable cargo transportation solutions.” – TST EBike Engineering Team

Frequently Asked Questions About Cargo Ebike Costs

Q: Why do cargo ebikes generally cost more than standard ebikes?

A: Cargo ebikes have reinforced frames, bigger batteries, and stronger motors to handle heavy loads, increasing manufacturing costs.

Q: Can I save money by converting a standard ebike into a cargo ebike?

A: It’s often less efficient and safe than buying a purpose-built cargo ebike designed to handle additional stress.

Q: Do cargo ebikes cost more to maintain?

A: Slightly, due to heavier use of brakes and drivetrain components and the need for regular safety inspections.

Q: Are cargo ebikes worth the higher price?

A: Yes, if you regularly transport heavy or bulky items, the durability and safety are essential investments.

Q: How do battery size and motor power affect cargo ebike prices specifically?

A: Larger batteries maintain range under heavy load, and powerful motors ensure consistent performance, both expensive components.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.