Cargo bikes cost so much to own primarily due to their robust build, specialized features, and higher maintenance needs compared to regular bikes. Factors like premium materials, powerful electric motors, batteries, and added accessories contribute significantly to their overall price. Additionally, regular upkeep and parts replacement can add to the total cost of ownership for cargo bike users.

What Are the Main Reasons Cargo Bikes Cost So Much To Own?

Cargo bikes are more expensive due to their unique design and purpose. Unlike standard bicycles, they need to carry heavier loads, which requires reinforced frames, stronger brakes, and wider tires—components that inherently increase cost. Additionally, many cargo bikes come with electric assist systems that add to both initial purchase and operating expenses, elevating the overall cost of ownership.

Chart: Cost Breakdown of Cargo Bike Components

| Component | Percentage of Total Cost |

|---|---|

| Frame and Build Quality | 35% |

| Electric Motor & Battery | 30% |

| Accessories | 15% |

| Maintenance | 10% |

| Other (Shipping, Fees) | 10% |

How Do Build Quality and Materials Affect Cargo Bike Prices?

The durability required for cargo bikes means manufacturers use premium materials such as high-grade aluminum or steel alloys, increasing fabrication expenses. The frame must handle extra weight without compromising safety or performance. This commitment to quality drives up the MSRP and retention of value, but it also means higher upfront costs and more careful, often costly repairs if damage occurs.

Why Do Features Like Electric Motors and Batteries Increase Costs?

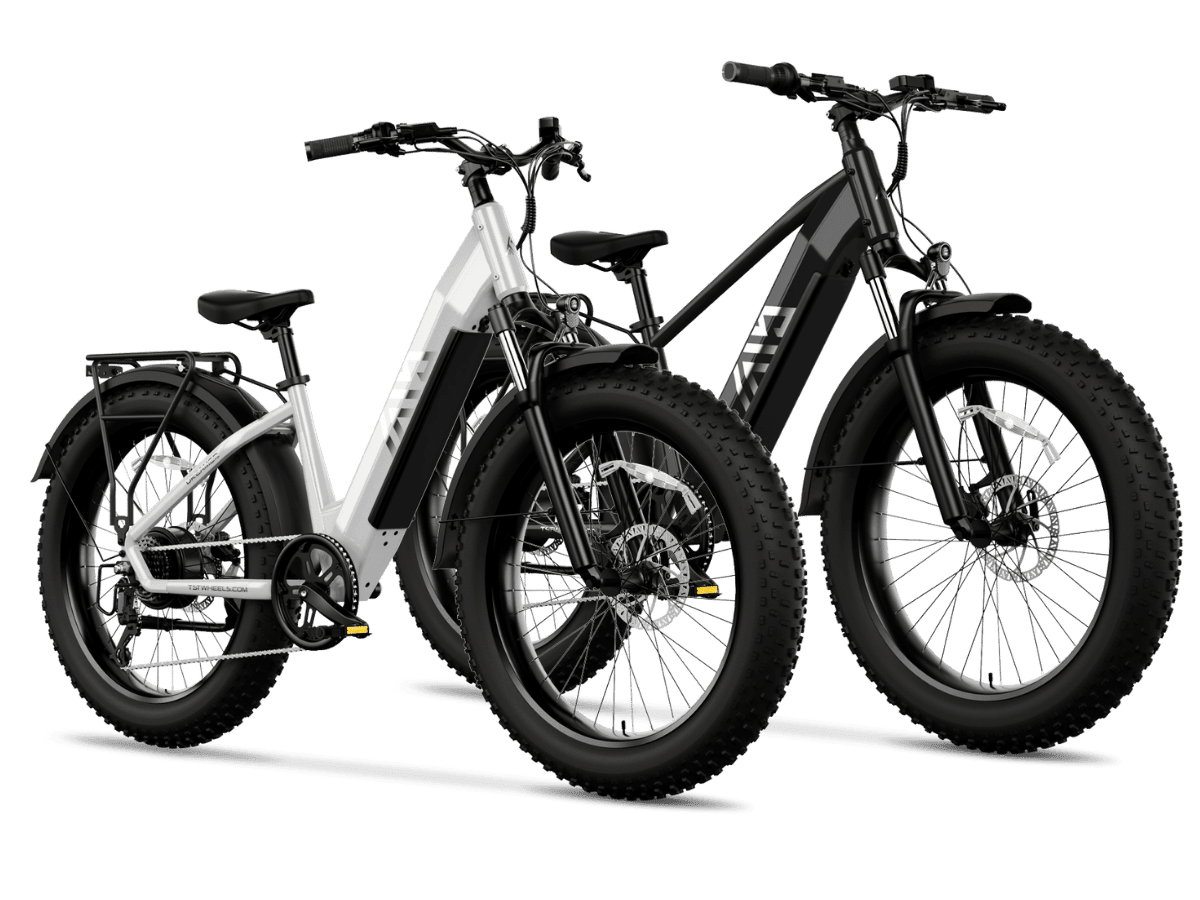

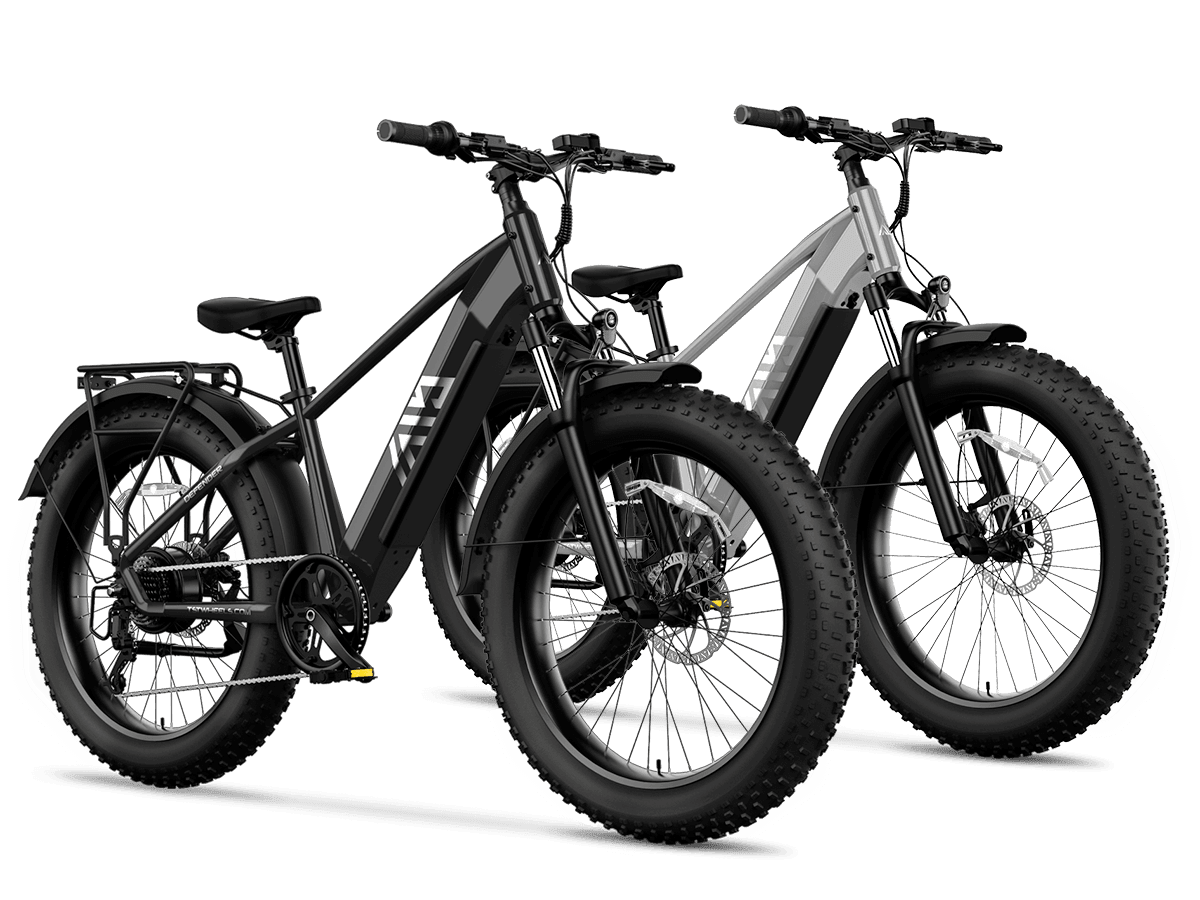

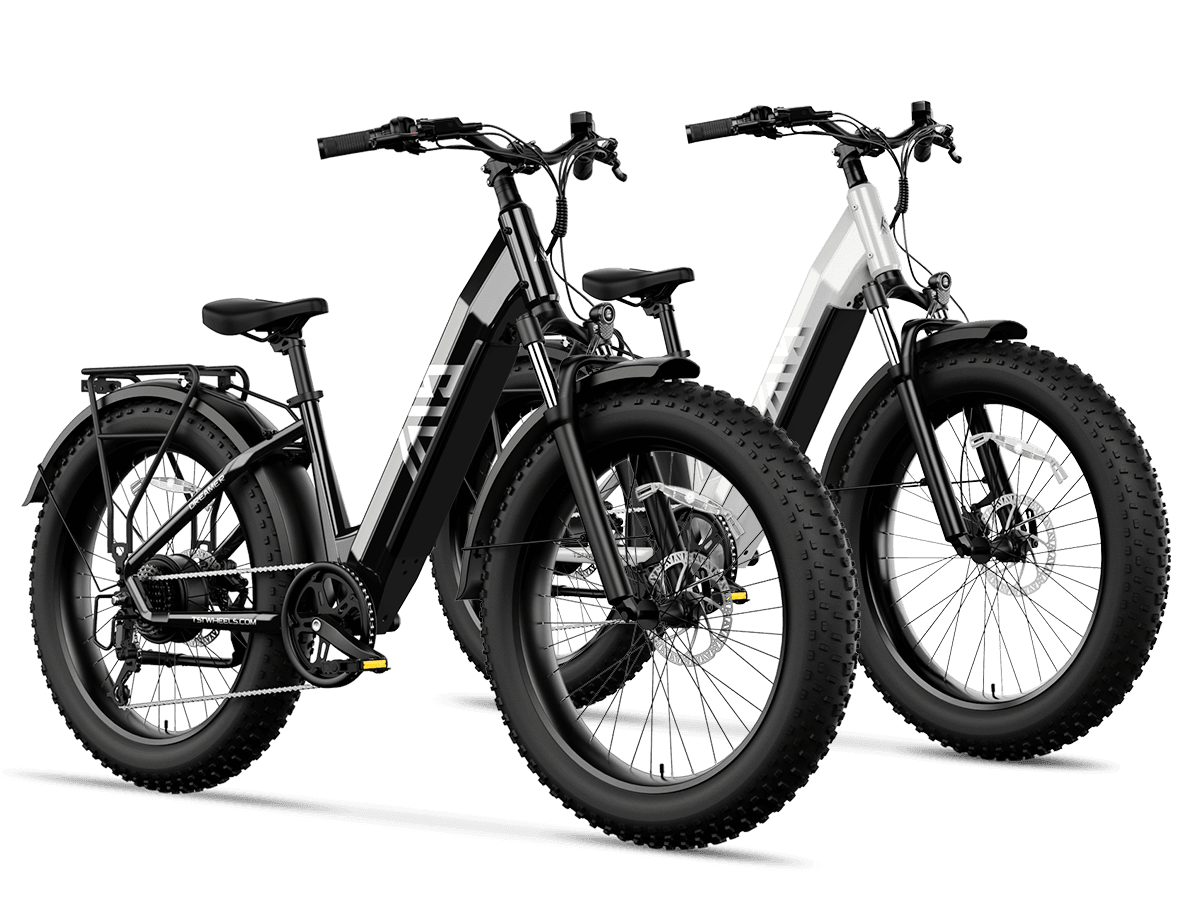

Electric cargo bikes equipped with motors and lithium-ion batteries significantly elevate the purchase price due to the technology and engineering involved. Batteries have limited lifespans and eventual replacement costs. Motors need specialized maintenance, and more powerful electric systems designed to handle heavy cargo contribute to higher initial and ongoing expenses. TST EBike models, for example, provide a range of electric assist options built to balance power and cost, but these features naturally increase ownership expenditure.

What Are the Typical Maintenance and Repair Costs of Cargo Bikes?

Because cargo bikes often carry heavy loads regularly, components experience accelerated wear and tear, leading to frequent brake adjustments, tire replacements, and drivetrain maintenance. Electric parts require occasional servicing, and battery packs can lose capacity over time, necessitating replacement. Factoring these ongoing costs is essential for anyone considering owning a cargo bike.

Chart: Average Yearly Maintenance Costs for Cargo Bikes

| Maintenance Type | Estimated Annual Cost |

|---|---|

| Tire and Brake Service | $100 - $200 |

| Battery Replacement | $300 - $600 (every 3-5 years) |

| Motor Servicing | $100 - $250 |

| General Tune-ups | $150 - $300 |

How Do Usage and Accessories Influence Overall Ownership Expenses?

The degree of use and the accessories added to cargo bikes, such as rain covers, child seats, or cargo boxes, add to the total cost of ownership. Heavy daily use accelerates maintenance needs. Adding features for convenience or utility, despite improving usability, substantially increases the upfront price and subsequent care costs.

What Can Potential Owners Do to Manage and Reduce Cargo Bike Costs?

Cost management strategies include choosing simpler builds without electric assists, performing regular DIY maintenance, and purchasing high-quality accessories selectively. TST EBike offers cost-effective models with durable designs ideal for diverse terrains, providing alternatives that balance quality and expense. Shopping for warranties and parts availability also helps reduce unforeseen costs in the long term.

What Buying Tips Should You Keep in Mind When Purchasing a Cargo Bike?

- Evaluate your primary use to decide between electric or manual cargo bikes.

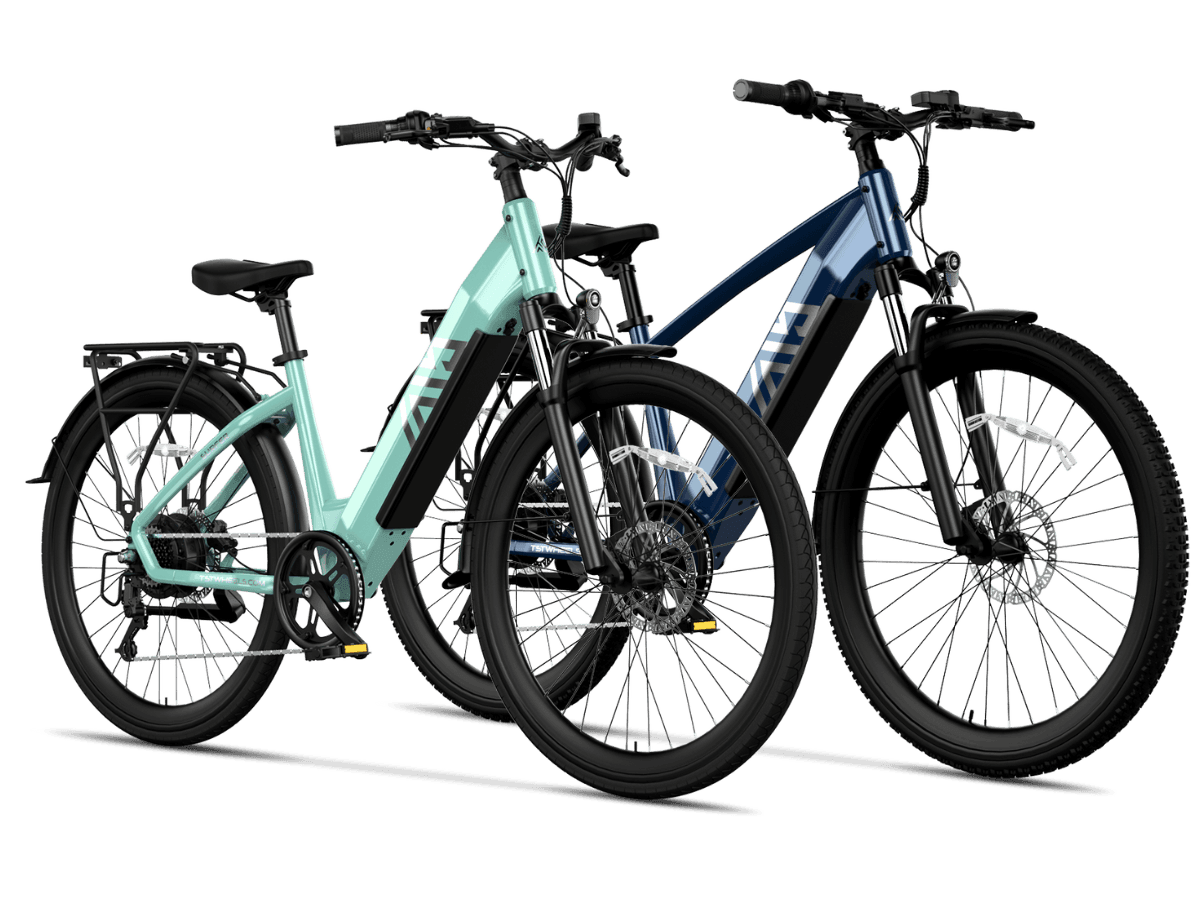

- Consider frame size and wheel options such as 26-inch for rough terrains or 27-inch for daily commuting.

- Prioritize brands with strong service networks like TST EBike for reliable parts and repairs.

- Account for long-term maintenance costs in your budget.

- Test ride models where possible to understand comfort and handling under load.

- Invest in necessary safety and weather protection accessories.

TST EBike Expert Views

"TST EBike focuses on providing power-efficient, cost-effective electric cargo bikes with durability for users from commute to cargo hauling," says a company representative. "By emphasizing consumer feedback, we fine-tune our designs and services to reduce ownership costs while maximizing utility. Our 26-inch and 27-inch electric bike models cater to rough terrain and daily city usage, balancing performance with affordability," they added.

FAQ: Common Questions About Cargo Bike Ownership Costs

Q: Why are electric cargo bikes more expensive than manual ones?

A: Electric bikes have costly batteries and motors that require maintenance and replacement over time, increasing ownership expenses.

Q: How often do batteries in electric cargo bikes need replacement?

A: Usually every 3 to 5 years, depending on usage and charging habits.

Q: Can maintenance costs be reduced with DIY care?

A: Absolutely, regular DIY tune-ups and minor repairs can save money, but some services require professional attention.

Q: Are cargo bikes a good investment compared to cars?

A: Yes, for many urban and short-range cargo needs, the lower operating and environmental costs make them a practical alternative.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.