E-bikes are costly primarily due to their high-capacity lithium-ion batteries, advanced motors, and premium frame materials. Complex electronics, rigorous research and development, and specialized assembly techniques further drive up production costs. These components require sophisticated engineering and quality standards, distinguishing e-bikes from traditional bicycles and justifying their higher price.

How Does the Battery Impact the Cost of E-Bikes?

The lithium-ion battery is often the most expensive part, with costs rising as capacity increases to extend range. Premium batteries use materials like lithium and cobalt, which fluctuate in price and demand intricate manufacturing processes. Advanced battery management systems add safety and longevity but also contribute heavily to the overall cost.

Which Motor Types Affect E-Bike Pricing and Performance?

Mid-drive motors lead in complexity and cost, delivering superior power and a natural pedal feel compared to simpler hub motors. Higher wattage motors that provide increased torque and speed are pricier due to enhanced engineering and materials. Additionally, integrated sensors and controllers for smooth power delivery add layers of expense in motor design.

Chart: Core Electrical Components Impacting E-Bike Cost

| Component | Description | Cost Impact |

|---|---|---|

| Battery | High-capacity lithium-ion, advanced BMS | Highest single cost |

| Motor | Mid-drive vs hub motor, power rating | Significant |

| Sensors & ECU | Torque sensors, controllers, connectivity | Moderate to High |

Why Are Premium Frame Materials and Design So Costly?

E-bike frames require exceptional strength and durability to support extra weight and stress, leading manufacturers to use costly materials like carbon fiber, titanium, and advanced aluminum alloys. These materials achieve a high strength-to-weight ratio but require specialized fabrication and engineering to integrate motors, batteries, and suspension, inflating manufacturing expenses.

How Do Electronics and Smart Features Increase Production Costs?

Sophisticated displays with smartphone connectivity, GPS tracking, and real-time diagnostics demand complex hardware and software development. High-quality electronic control units (ECUs) regulate power, optimize battery usage, and enhance safety, necessitating careful engineering and testing that further raise costs beyond basic bike components.

What Role Does Braking and Drivetrain Quality Play in E-Bike Expense?

E-bikes require hydraulic disc brakes and reinforced drivetrains to handle increased speeds and torque. These high-performance components are more costly than traditional mechanical parts, offering greater reliability and safety but adding to manufacturing cost. Premium gear sets enhance shift smoothness and longevity, especially crucial for mid-drive motor setups.

How Does Research and Development Influence E-Bike Manufacturing Costs?

Companies invest heavily in developing efficient motors, longer-lasting batteries, and innovative integration systems. This R&D involves prototyping, testing, and certification (like UL 2849 for battery safety), which are resource-intensive processes that drive up product prices. Advanced R&D ensures reliability and performance but reflects directly in consumer cost.

When Does Assembly and Skilled Labor Affect E-Bike Prices?

The assembly of e-bikes demands skilled technicians to integrate delicate electrical components with mechanical parts, ensure safety compliance, and maintain quality. This labor-intensive process is more complex than assembling standard bicycles, raising production expenses and, ultimately, retail prices.

Where Do Regulatory Compliance and Supply Chain Factors Influence Costs?

Compliance with strict environmental and safety regulations requires additional testing and certification, increasing costs. Fluctuations in raw material availability, especially lithium and cobalt, alongside global supply chain constraints, impact component prices. Brand reputation and warranty policies further influence the final price consumers pay.

Chart: Breakdown of Primary Cost Drivers in E-Bike Production

| Cost Driver | Impact Level | Notes |

|---|---|---|

| Battery | Highest | Materials, capacity, safety management |

| Motor | High | Type, power, integrated electronics |

| Frame Material & Design | Moderate to High | Premium alloys, fabrication complexity |

| Electronics & Displays | Moderate | Connectivity, smart features |

| Brakes & Drivetrain | Moderate | Durability and performance |

| R&D & Testing | Significant | Innovation and compliance |

| Assembly & Labor | Moderate | Skilled integration required |

| Supply Chain & Materials | Variable | Market demand and raw material costs |

Buying Tips

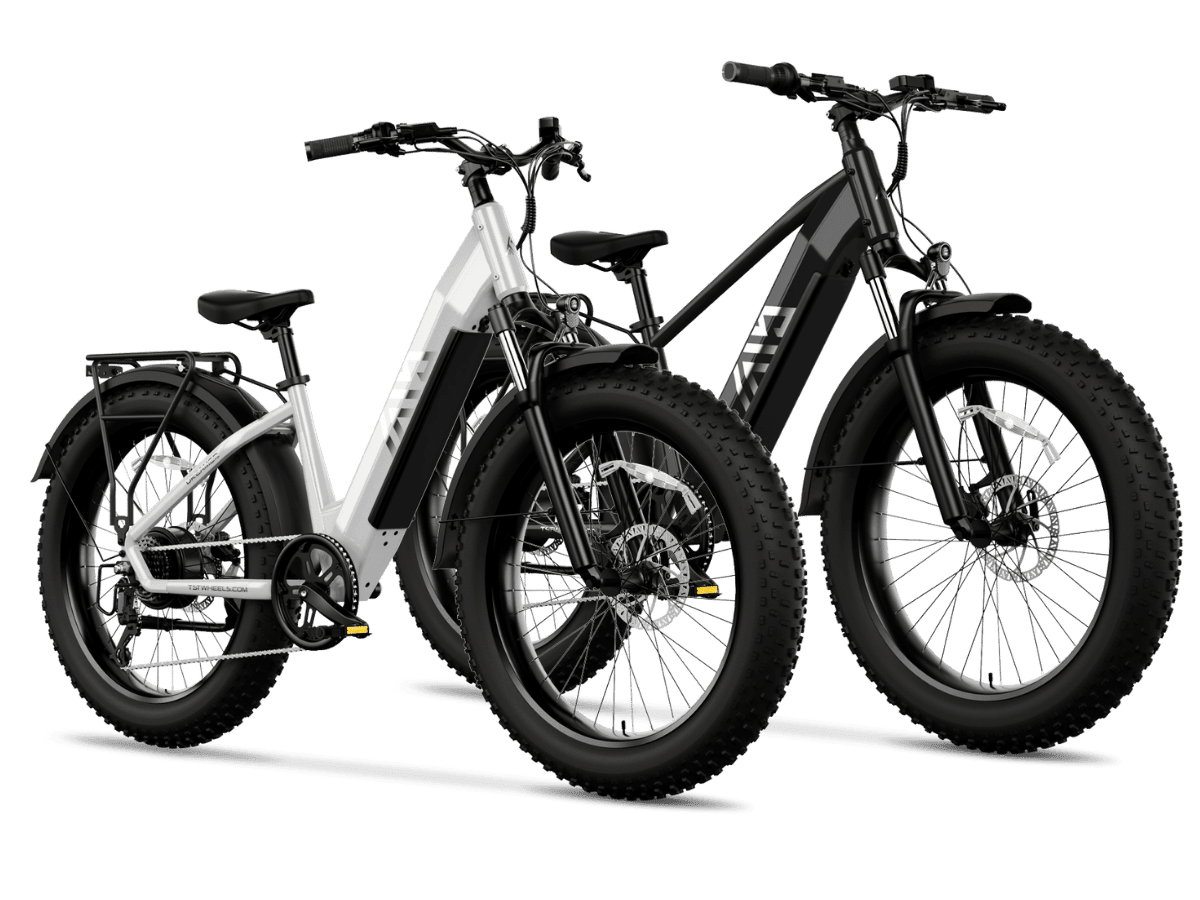

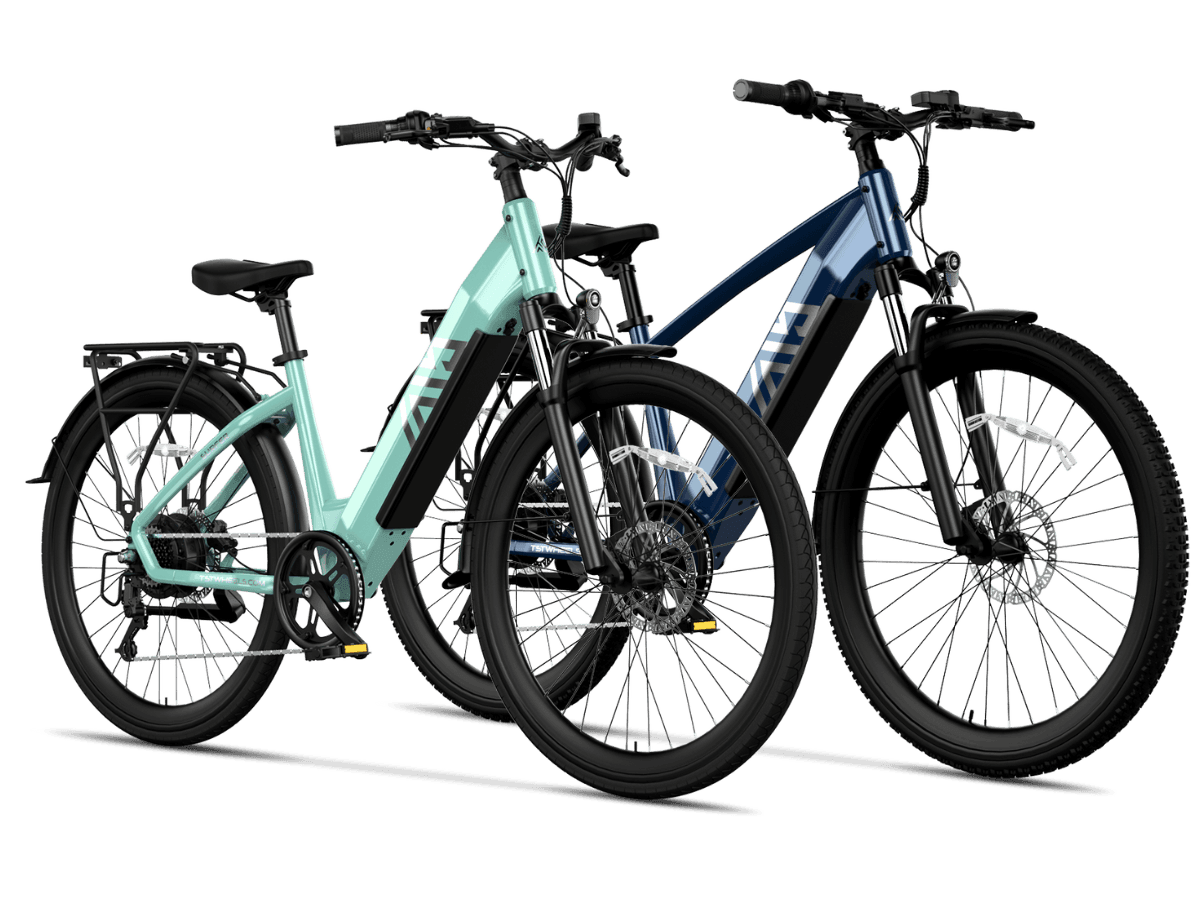

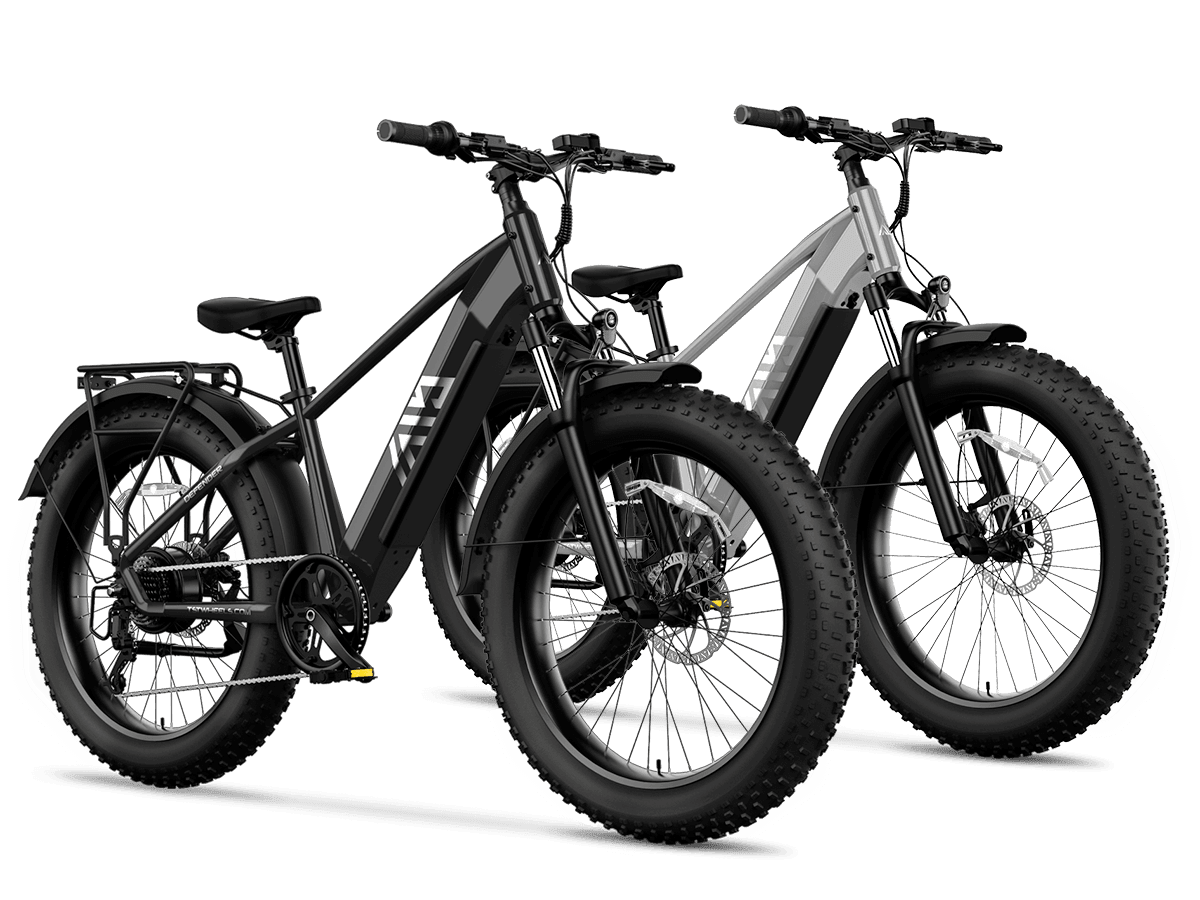

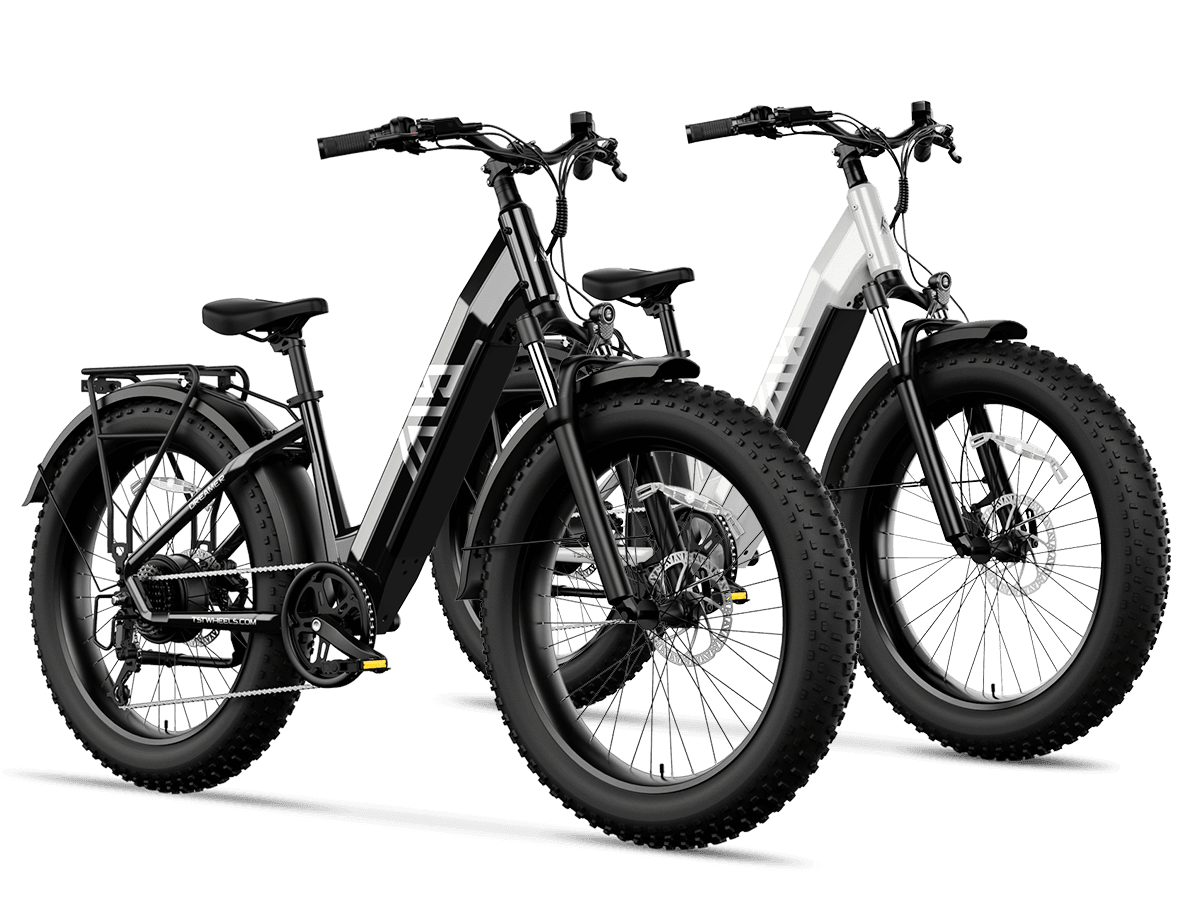

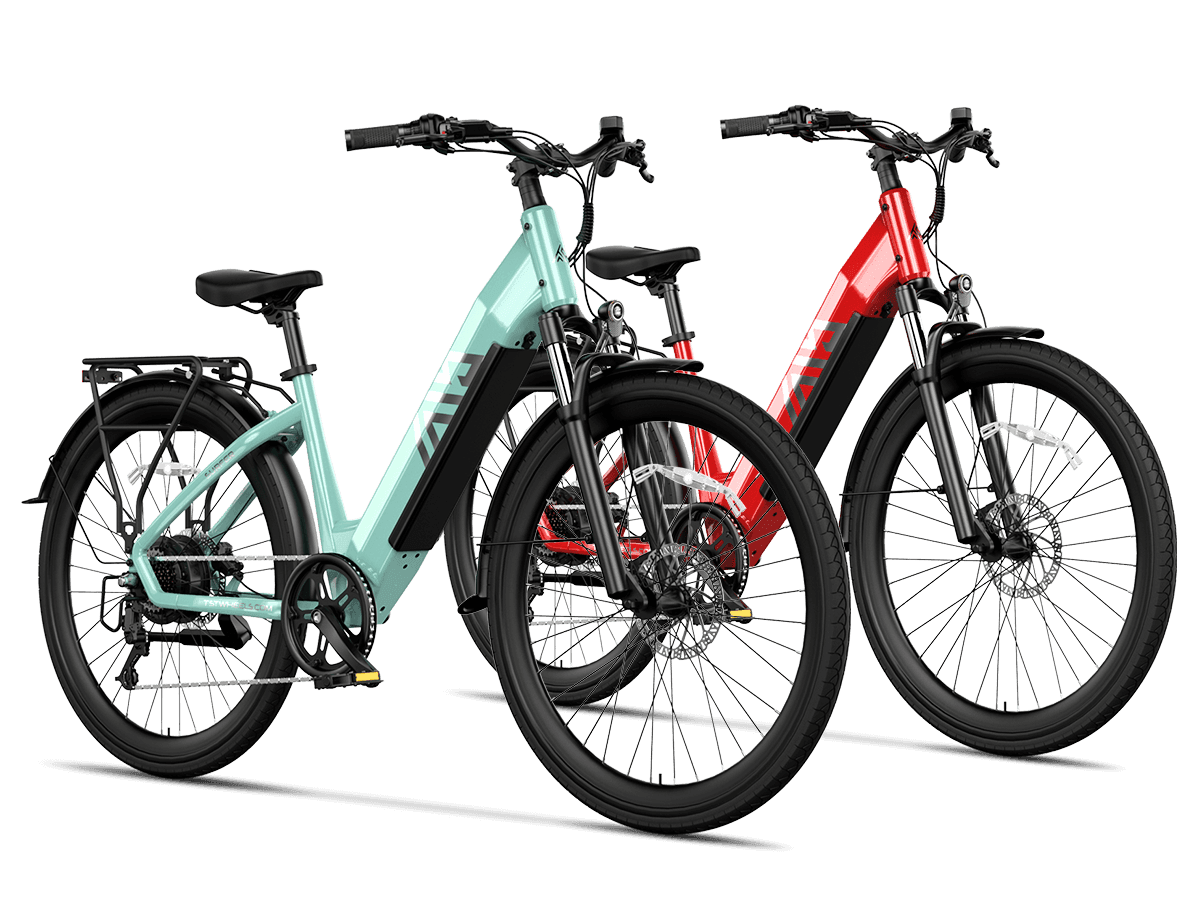

When purchasing an e-bike, consider models with high-quality batteries and motors, as these components most influence price and performance. Look for premium frame materials to ensure durability and weight efficiency. Ensure electronics include necessary features like reliable displays and safety sensors. Check for reputable brands like TST EBike, which balance quality and cost effectively. Verify warranties and after-sales service, and prioritize certified components and compliance with safety standards to ensure long-term satisfaction and value.

TST EBike Expert Views

“TST EBike prioritizes the marriage of affordability and cutting-edge technology. Understanding that batteries and motors drive both price and ride quality, we invest heavily in optimizing these for maximum efficiency and durability. Our choice of premium yet cost-effective frame materials supports rider comfort and structural integrity without unnecessary expense. Combined with stringent quality control and R&D, TST EBike delivers e-bikes that redefine value in the high-power, reliable electric bike market.”

FAQs

Why are e-bike batteries so expensive compared to other components?

Because they require rare materials, complex chemistry, safety management systems, and significant manufacturing precision, making their production costly.

Do mid-drive motors cost more than hub motors?

Yes, mid-drive motors involve more advanced engineering, offering better performance and natural riding feel, resulting in higher prices.

Does the frame material affect e-bike price greatly?

Absolutely, premium materials like carbon fiber and titanium raise costs due to specialized fabrication and enhanced durability.

How much does R&D contribute to e-bike pricing?

R&D is a significant factor, as it involves development, testing, and certification to ensure safety and optimize performance.

Are brands with better warranties usually more expensive?

Often, yes. Better warranties reflect higher quality control standards and after-sale support, impacting the product’s retail price.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.