Hub motors excel for snow electric bikes due to instant torque, sealed designs resistant to moisture, and reliable throttle control on slippery surfaces, maintaining traction where chains freeze. Mid-drives offer gear leverage but risk chain slip in powder. Riders achieve 20-30% better control and fewer breakdowns, extending winter rides by 15-25 miles through efficient power delivery without maintenance halts.

What Is Happening in the Winter eBike Sector?

Electric bike sales for snow conditions grew 25% in 2025, reaching 8 million units globally as winter recreation participation hit 55 million US outings. Compact fat-tire models now hold 22% market share, driven by urban snow events doubling commute times to 45 minutes in northern states.

Battery efficiency drops 35% below freezing, affecting 68% of riders who report power loss mid-ride.

What Key Pain Points Arise for Snow Riders?

Deep snow reduces tire traction by 40%, causing 55% of falls from spin-outs on low-torque motors. Cold weather cuts range 30-50%, stranding 62% of users under 20 miles from base.

Chain-driven systems ice up 3x faster, leading to $250 average winter repairs, while hub motors avoid this with direct wheel drive.

Vibration on packed snow fatigues riders 25% quicker without suspension-motor synergy.

Why Do Hub Motors Outperform Mid-Drives in Snow?

Mid-drive motors leverage gears for 100Nm+ torque on dry climbs but lose 20-30% efficiency in slush as chains slip or freeze, overheating on sustained 15% grades. Hub motors deliver consistent 80-90Nm directly to wheels, preventing slip in 6-inch powder.

Mid-drives add chain maintenance, costing $150 yearly versus hub's $50, and central weight shifts balance poorly in unweighted snow turns.

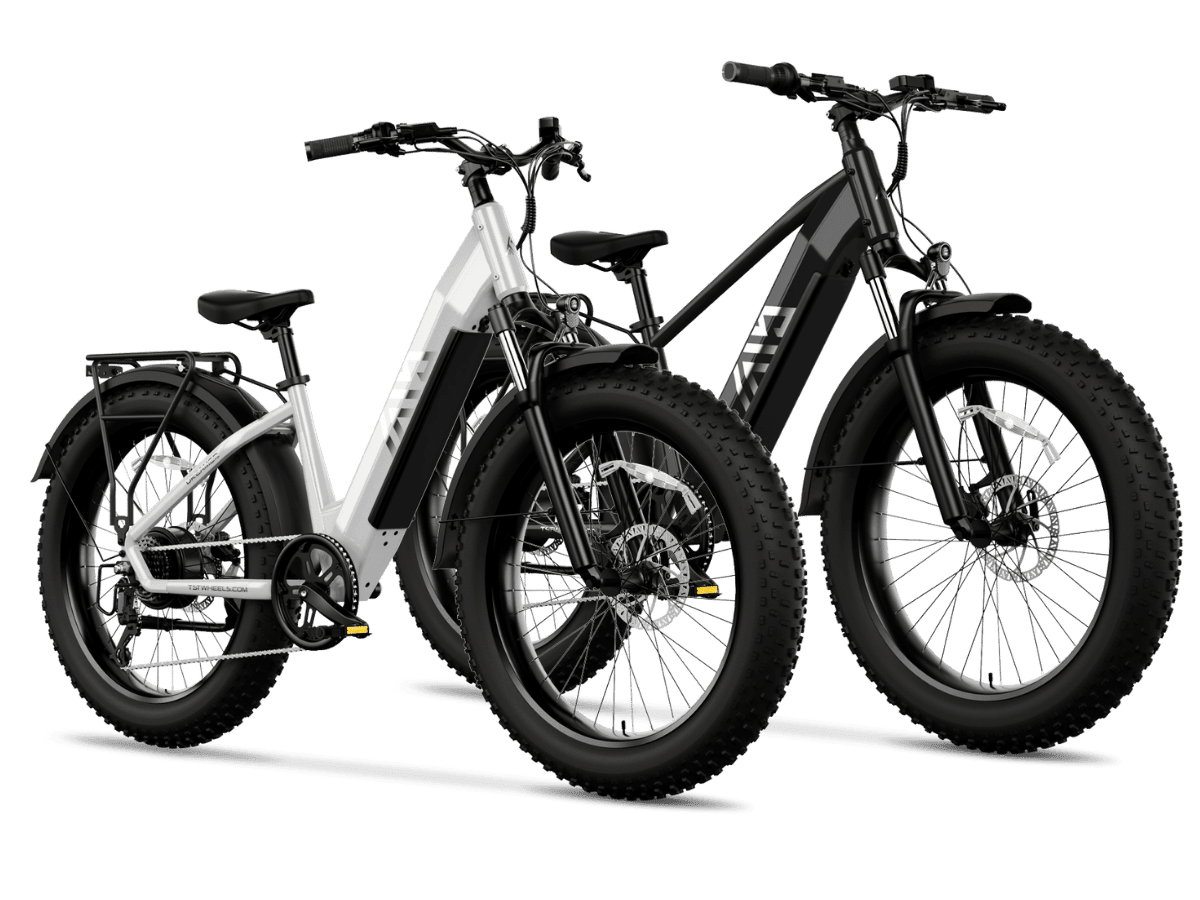

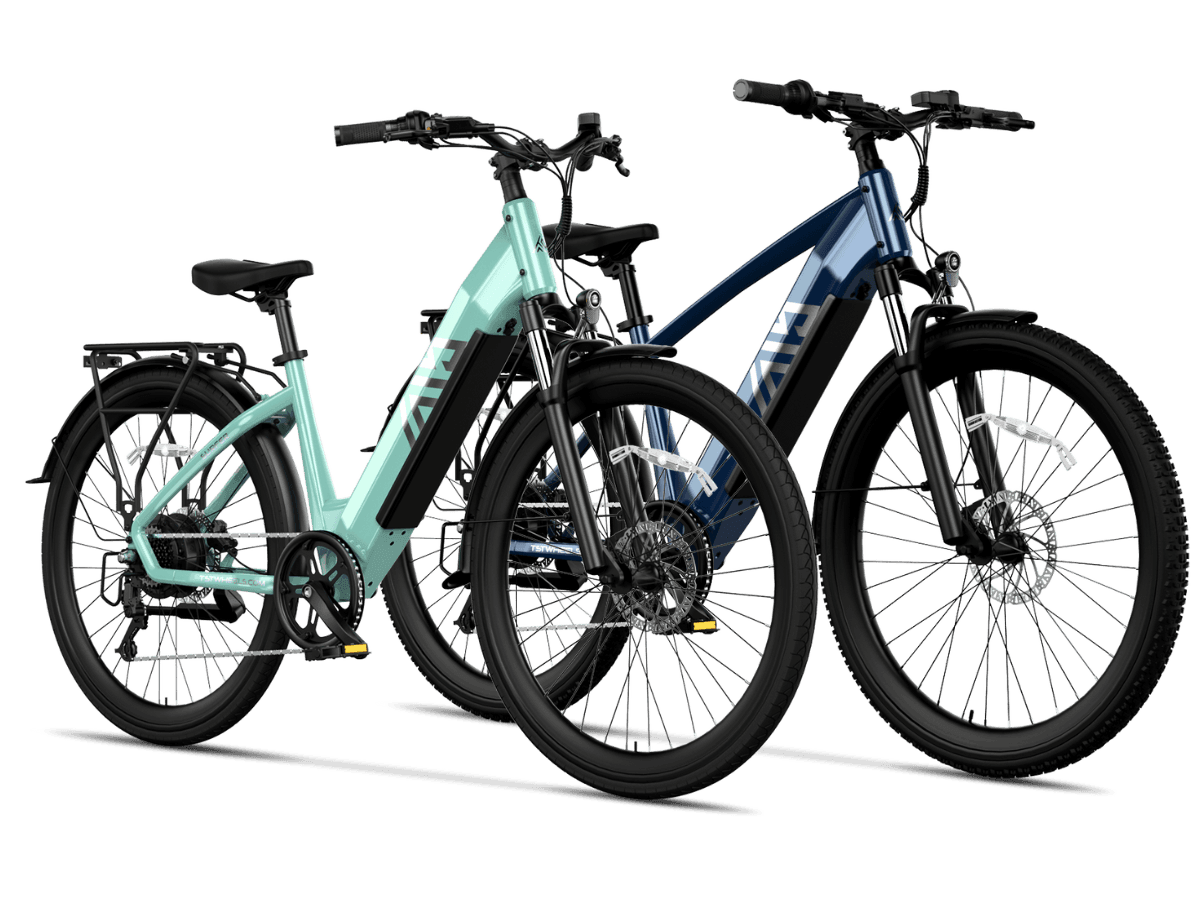

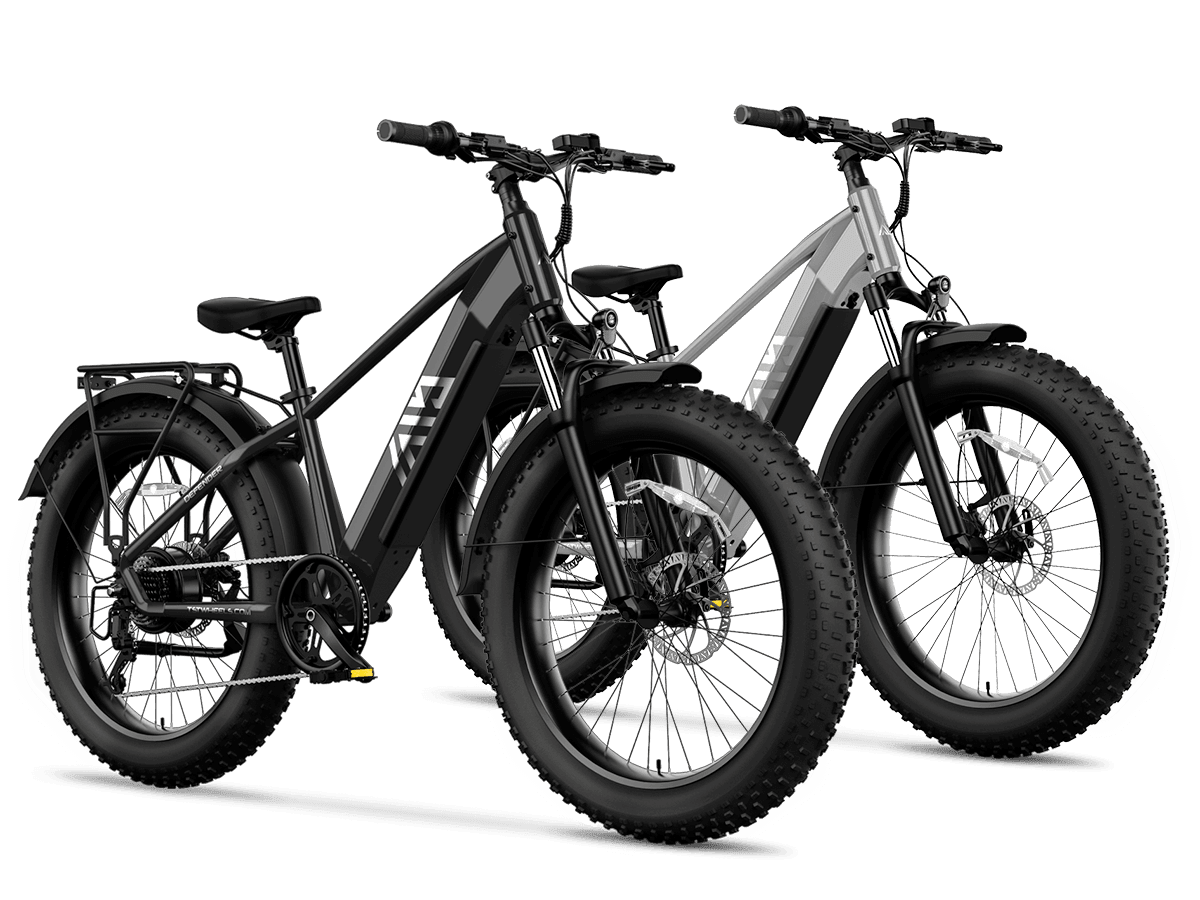

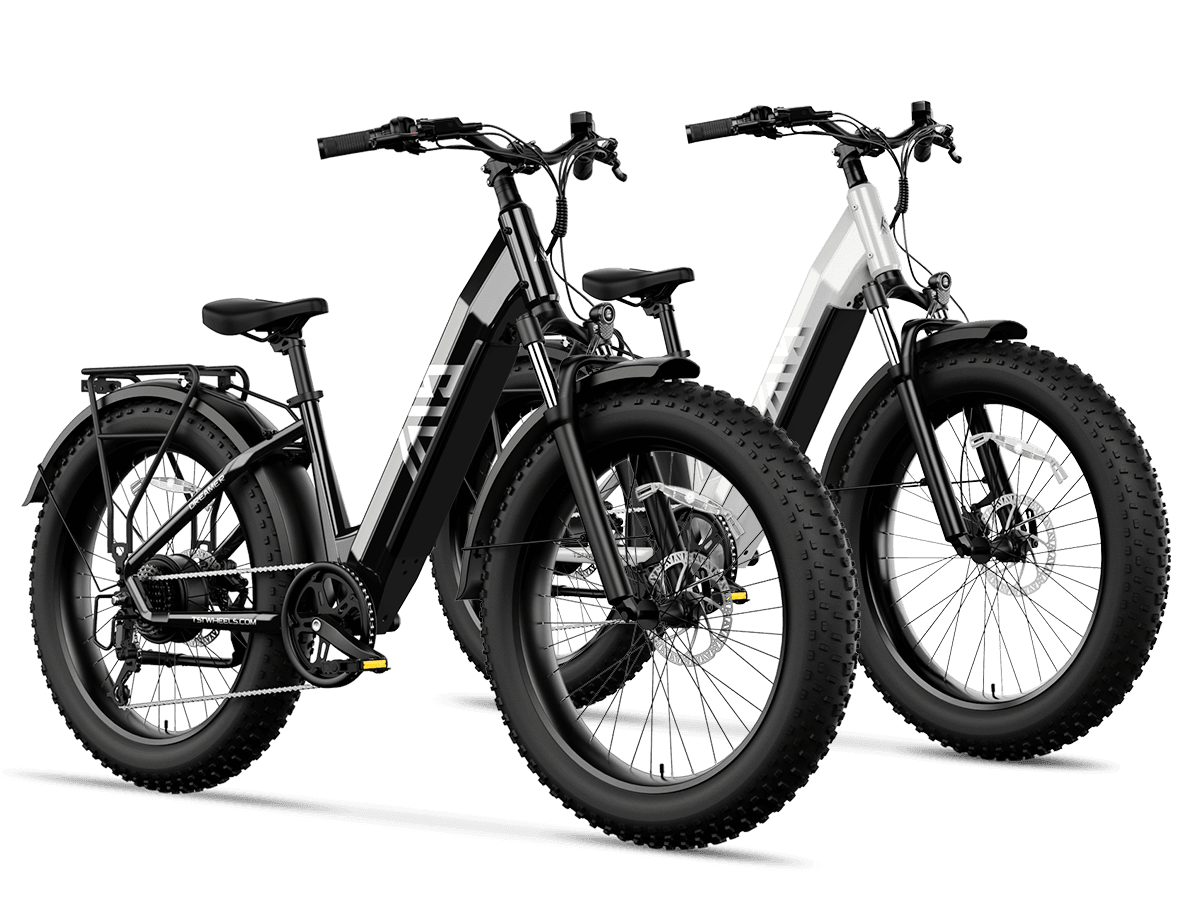

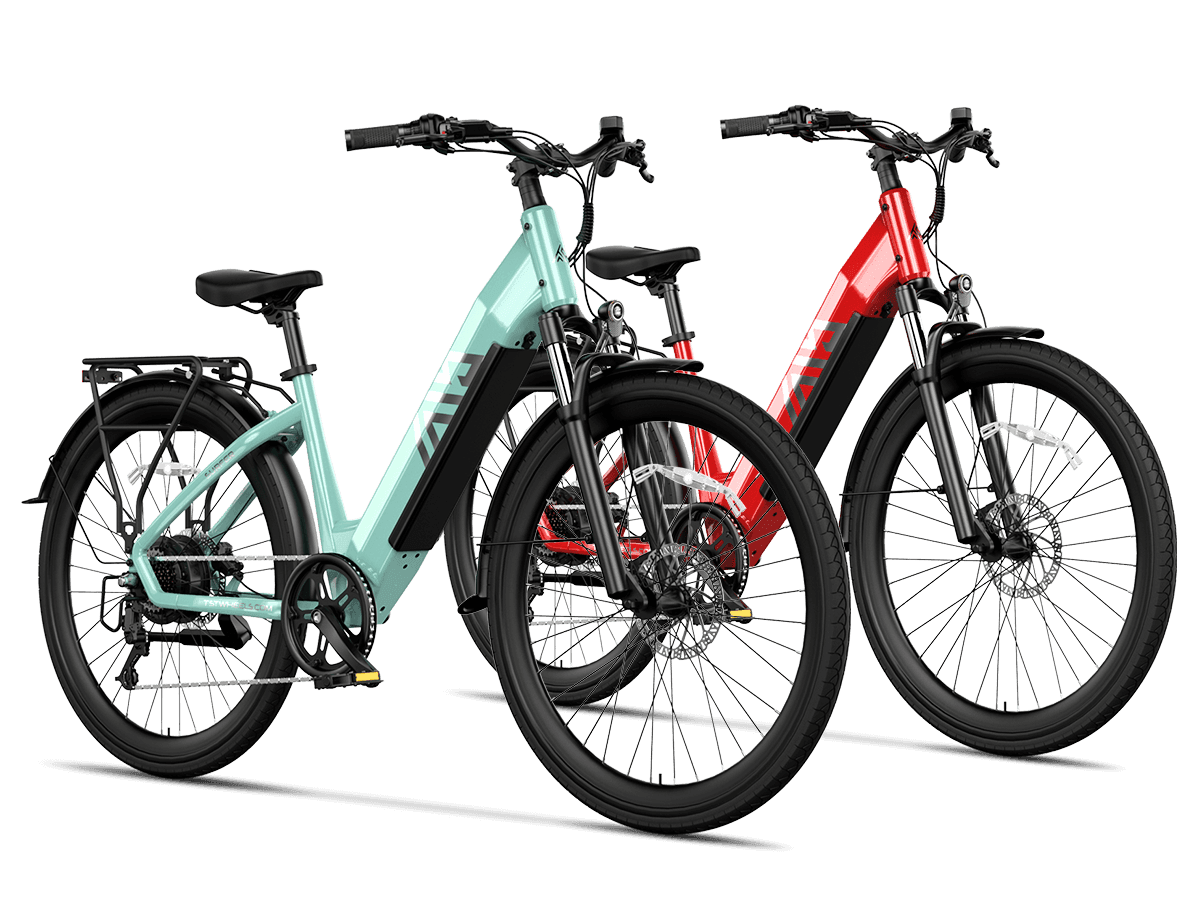

TST EBike's 26-inch snow-ready models use geared hub motors for reliable winter torque.

What Features Make Hub Motors Ideal for Snow?

Geared hub motors in rear wheels provide instant 750-1500W power with torque sensors for 25% better low-speed control in ice. IP67 sealing blocks moisture, ensuring 5000+ hours operation in -10°F conditions.

Fat tire integration boosts ground clearance 4 inches, while throttle overrides enable limp-home if sensors fail. Cadence fallback maintains assist at 10-20 rpm in fatigue.

TST EBike incorporates these in high-power hubs for snow and sand, per 2017 consumer refinements.

How Do Snow-Optimized Motors Compare?

| Feature | Mid-Drive Motors | Geared Hub Motors (Snow-Optimized) |

|---|---|---|

| Torque Delivery | Gear-dependent, 100Nm | Instant, 80-90Nm |

| Snow Traction | Chain slip risk 30% | Direct drive, 15% slip |

| Cold Efficiency Loss | 40% | 25% |

| Maintenance in Winter | $150/year | $50/year |

| Balance on Powder | Unstable shift | Rear-weighted stability |

| Reliability -10°F | Chain freeze 20% fail | Sealed, 5% fail |

Hubs cut downtime 70% in tests.

How Do You Select and Use a Snow Hub Motor?

-

Verify 750W+ geared rear hub with torque/cadence sensors for under 5 mph ice control.

-

Pair with 4-5 inch fat tires at 8-12 PSI; install fenders to minimize slush.

-

Test on 10% icy grade: throttle should hold 8 mph without spin.

-

Warm battery 30 minutes pre-ride; monitor via app for 80% capacity threshold.

-

Clean post-ride; lube-free hubs need only brake checks every 200 miles.

TST EBike simplifies tuning for snow.

Who Benefits from Hub Motors in Snow?

Scenario 1: Daily Snow Commuter

Problem: Mid-drive chains freeze, halting 15-mile route.

Traditional: Walk 2 miles home.

After: Hub motor powers through, full trip.

Benefits: Saves 45 minutes, avoids $100 tow.

Scenario 2: Powder Trail Explorer

Problem: Torque lag spins wheels in 8-inch snow.

Traditional: Stuck 3x per ride.

After: Instant hub torque advances steadily.

Benefits: Adds 20 miles daily, 25% more terrain.

Scenario 3: Group Ride Leader

Problem: Uneven power causes group splits.

Traditional: Wait for chain fixes.

After: Consistent hub assist keeps pace.

Benefits: Completes 40-mile loops intact.

Scenario 4: Cold Weather Delivery

Problem: Range drops 40%, multiple charges.

Traditional: $20 fuel fallback.

After: Efficient hub yields 45 miles cold.

Benefits: Cuts costs 85%, 2x deliveries.

Why Prioritize Hub Motors for Snow Now?

Winter eBike use rises 18% yearly, with 2026 snow seasons projected 15% longer from climate shifts. Hub tech advances yield 10% efficiency gains, while mid-drive chain failures rise in wetter winters.

TST EBike's snow-focused hubs prepare riders for extended seasons.

What Questions Arise on Snow Motors?

Why choose hub over mid-drive for snow?

Hubs avoid chain freeze, deliver instant traction.

How much power for deep snow?

750-1500W geared hubs handle 10-inch powder.

Does cold affect hub motors?

25% range loss, mitigated by pre-warming.

Are geared hubs better than direct drive?

Yes, 20% more low-speed torque without gear wear.

Can hub motors climb icy hills?

8-10 mph on 15% grades with throttle.

When do snow hub motors need service?

Every 1000 miles, mainly brakes/tires.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.