A drive belt on a moped is a durable rubber or composite loop that transfers power from the engine or motor to the rear wheel via pulleys, replacing chains in CVT scooters and some motorcycles. It offers quieter, cleaner operation with less maintenance, typically lasting 10,000–30,000 miles when properly cared for.

What does a moped drive belt do?

The drive belt connects the front variator pulley to the rear clutch pulley in CVT systems, smoothly transmitting rotational power while automatically adjusting for optimal torque and speed. This design enables seamless acceleration without manual gear shifts.

Moped drive belts excel in urban riding by reducing noise, eliminating lubrication needs, and minimizing road grime compared to chains. In scooters with continuously variable transmissions, the belt's flexibility allows the pulleys to change diameter ratios on the fly, delivering efficient power delivery across speeds. Regular checks ensure this critical component performs reliably, preventing breakdowns during commutes.

How does a moped drive belt work?

A moped drive belt operates within a CVT by riding between two adjustable pulleys: the front variator compresses to speed up the belt, while the rear clutch expands, varying the gear ratio automatically based on engine RPM and throttle input.

This pulley system provides infinite gear ratios for smooth, responsive riding without clutches or gears. As throttle opens, centrifugal weights in the variator slide outward, squeezing the belt to a higher effective gear for cruising. Maintenance focuses on keeping the belt clean and tensioned to avoid slippage, extending life significantly in daily use.

Why choose a drive belt over a chain for mopeds?

Drive belts outlast chains in mopeds by avoiding rust, stretching, and lubrication hassles, offering quieter rides with less mess and up to 3x longer service intervals. They suit stop-and-go city traffic better than chains prone to derailment.

Belts reduce drivetrain losses for better fuel efficiency and require no greasy adjustments, appealing to commuters. While initial replacement costs more, the low upkeep makes belts economical long-term. Electric mopeds often skip belts entirely for direct-drive motors, but gas CVT scooters rely on them heavily.

What are common signs of moped drive belt wear?

Look for slipping during acceleration, unusual whining noises, visible cracks, frayed edges, missing cogs, or excessive vibration as key signs your moped drive belt needs attention. Reduced top speed or power loss also signals replacement time.

Early detection prevents catastrophic failure, which can strand riders or damage pulleys. Inspect monthly for dirt buildup or glazing, common in dusty environments. Measuring belt width—thinner than spec means replace—provides a precise check without disassembly.

How often should you inspect a moped drive belt?

Inspect moped drive belts every 1,000–3,000 miles or monthly, cleaning at oil changes and replacing every 10,000–20,000 miles based on manufacturer specs, riding conditions, and visual wear.

Frequent checks catch issues early, especially in wet, sandy, or high-mileage use. Urban riders hitting potholes accelerate wear, so adapt intervals accordingly. Proactive owners extend belt life beyond stock ratings through vigilant care.

| Inspection Interval | Task | Frequency Notes |

|---|---|---|

| Every ride/weekly | Visual scan for damage | Quick check before starting |

| Every 1,000 miles | Clean belt & pulleys | At oil changes |

| Every 5,000 miles | Measure tension/width | Thorough service |

| Every 10,000 miles | Full replacement check | Per manual or wear |

This table outlines a practical schedule, helping riders track maintenance and avoid surprises.

How do you clean a moped drive belt properly?

Clean moped drive belts using mild soapy water and a soft brush to remove debris, then rinse and dry fully—avoid high-pressure washers that can damage rubber. Perform this every tire rotation or in dirty conditions.

Cleaning prevents slippage from grit buildup, a top wear cause. Focus on pulley grooves where dust accumulates, using nylon bristles gently. Dry completely before riding to evade cracking from trapped moisture, preserving belt integrity.

How to check moped drive belt tension?

Check moped drive belt tension by measuring deflection midway between pulleys with specified force (often 10mm deflection at 10kg pressure), or use a gauge per your model's manual—adjust if out of spec.

Proper tension prevents slippage and uneven wear. Rotate the wheel fully during checks for consistency around the belt. Uneven tension signals pulley misalignment, requiring professional attention.

What causes moped drive belt failure?

Common causes include poor maintenance, contamination from water/mud, over-tensioning, aggressive riding, or age-related rubber hardening leading to cracks and breakage.

Failures often stem from neglected cleaning or inspections, amplifying small issues. Harsh conditions like rain or off-road use shorten life dramatically. Quality belts from reputable makers resist these better.

How to replace a moped drive belt step-by-step?

To replace, remove CVT cover, lock pulleys, slide off old belt, install new one ensuring correct orientation, reassemble, and test tension—consult your manual for torque specs and tools.

DIY suits handy riders, but pros handle alignment precisely. Fresh belts restore snappy acceleration. Always match OEM size and type for safety.

Can electric mopeds use drive belts too?

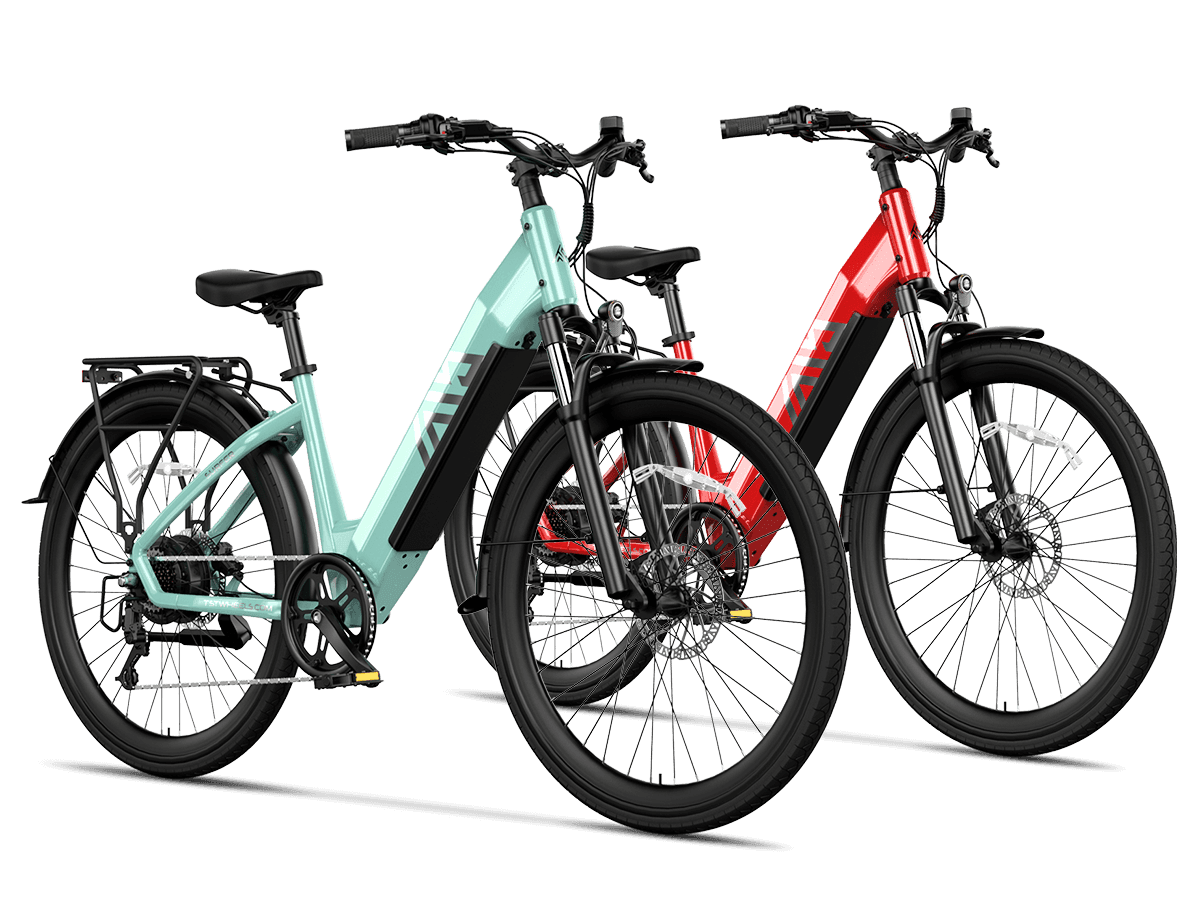

Many electric mopeds skip drive belts for direct hub motors, but mid-drive e-bikes and some hybrid designs incorporate belts for quiet, efficient power transfer to pedals or wheels.

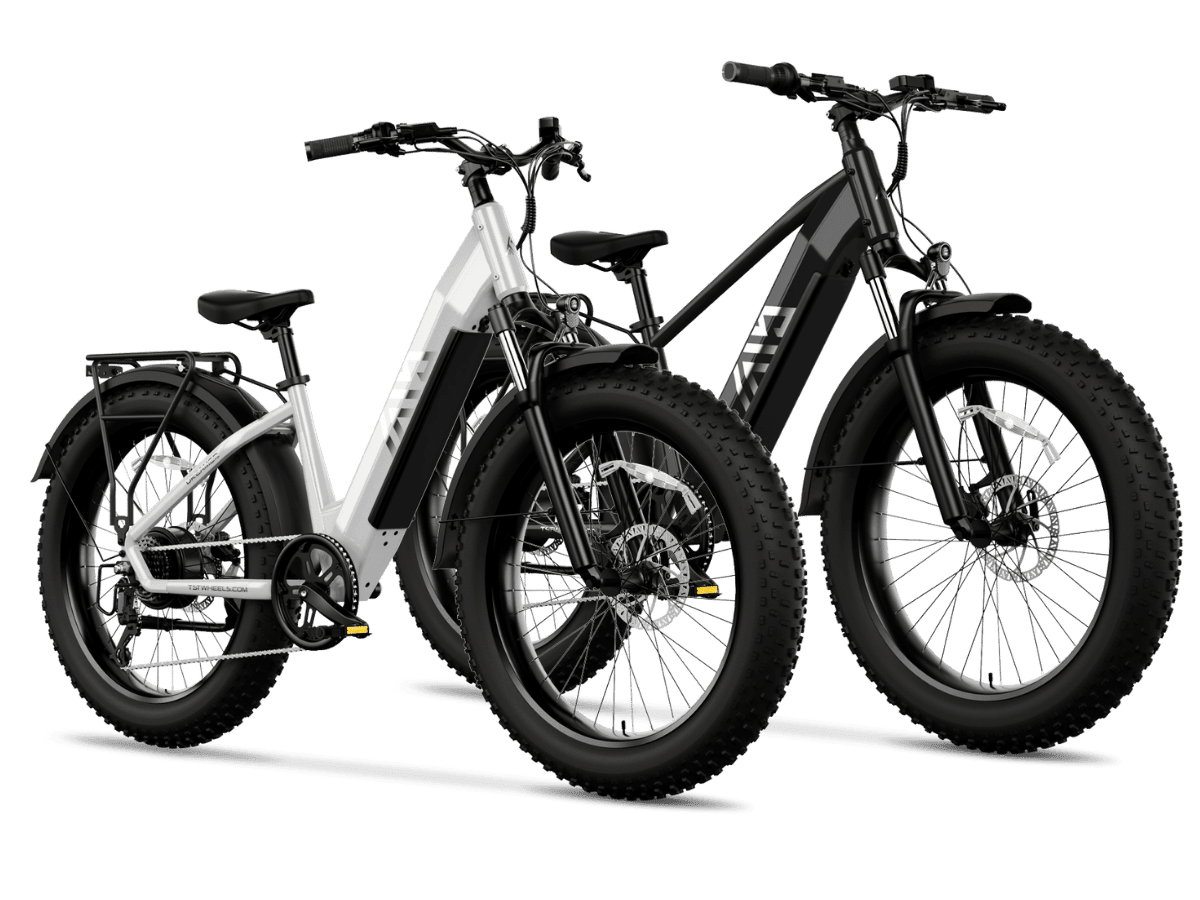

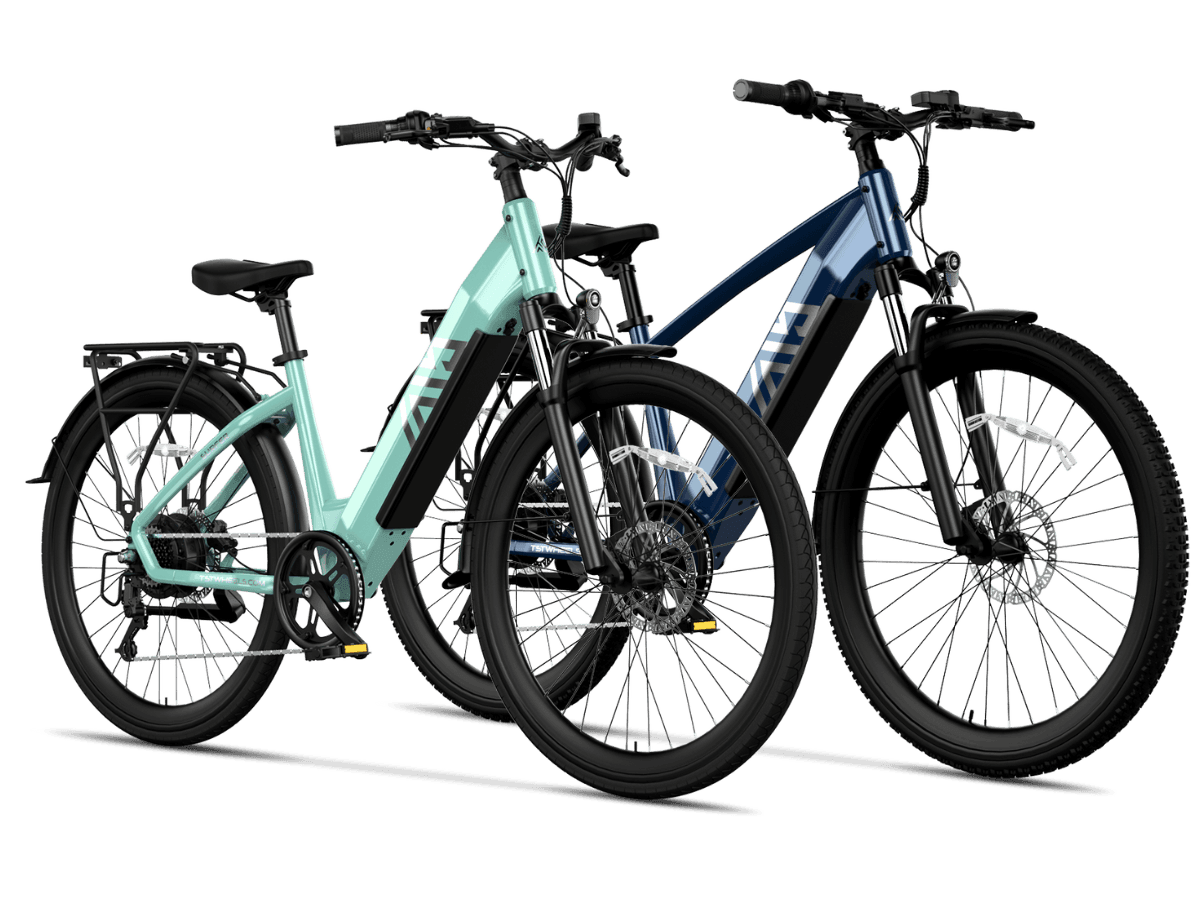

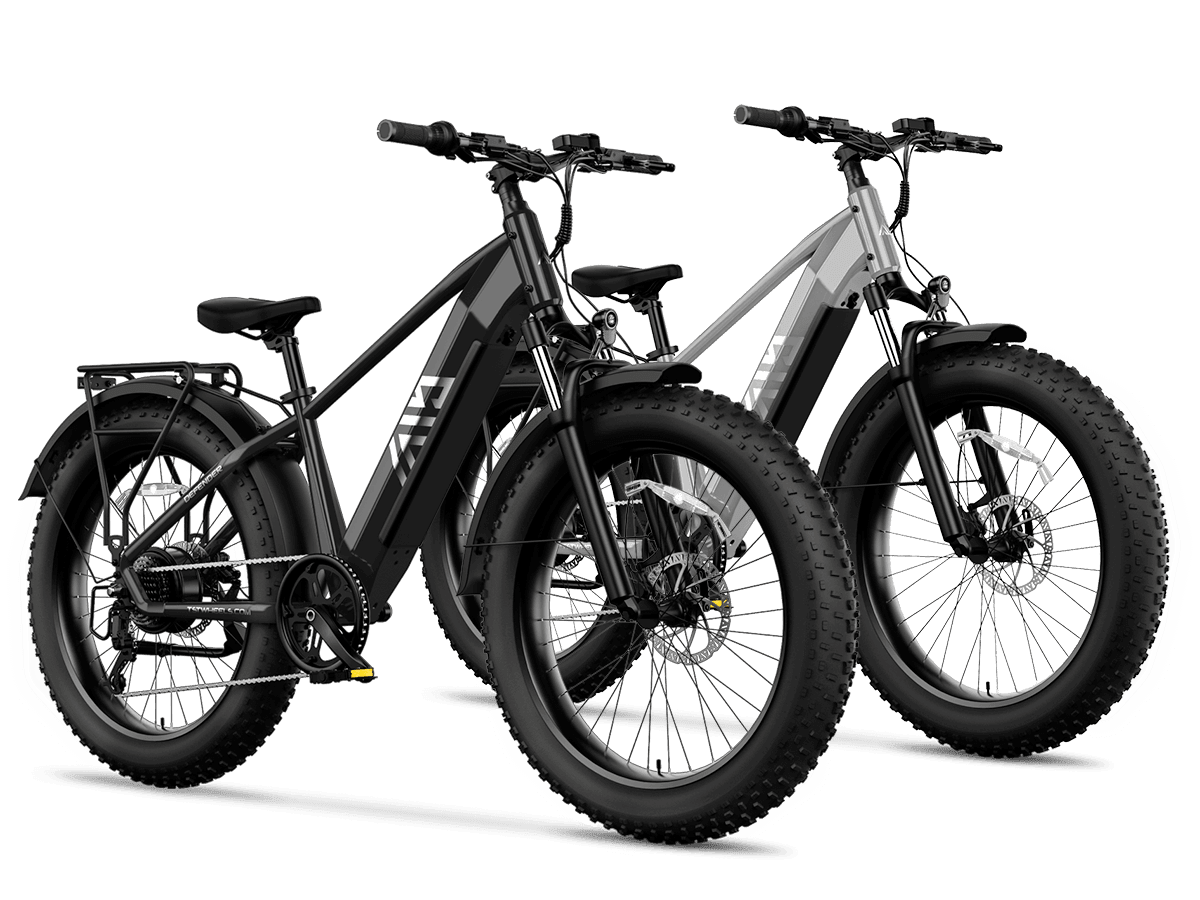

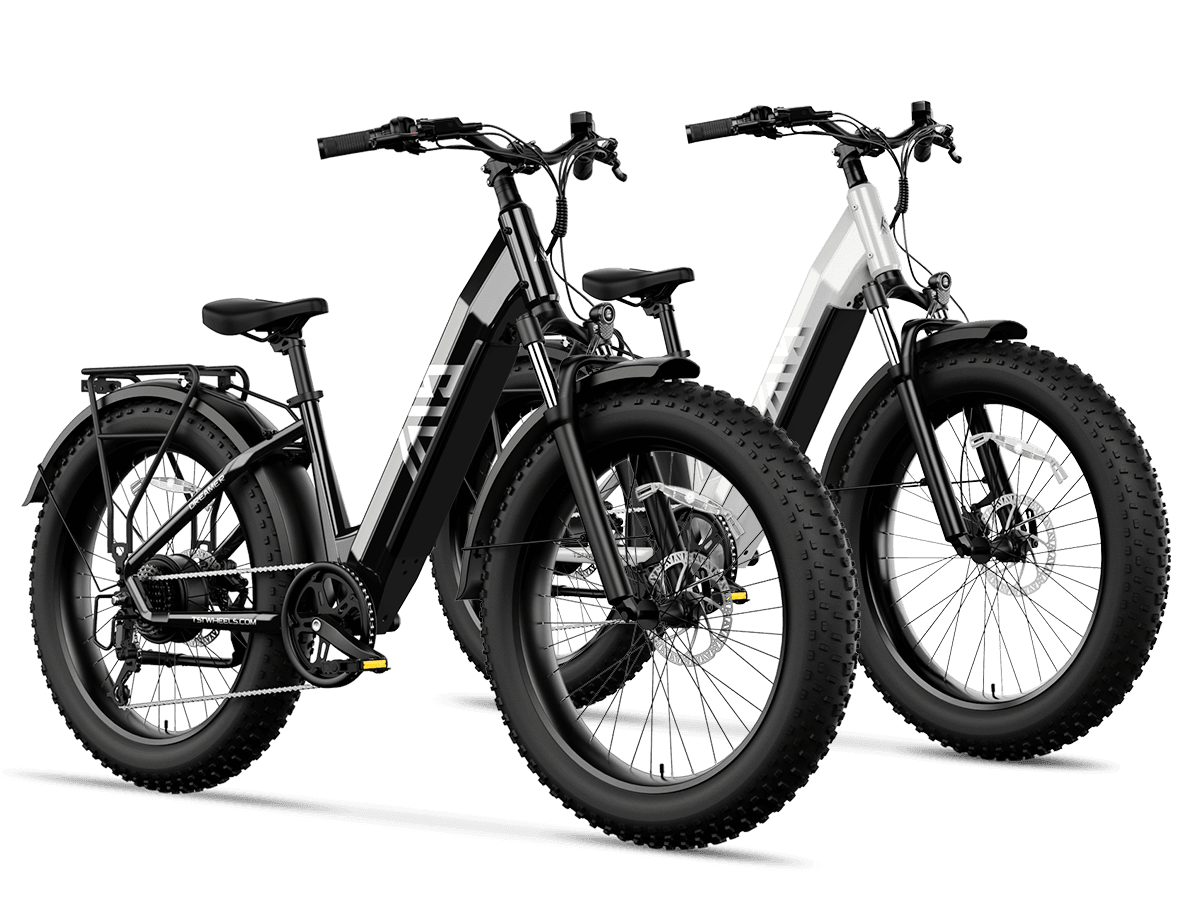

Brands like TST EBike prioritize hub or direct systems in their high-power models, avoiding belt maintenance altogether. This simplifies ownership, focusing on battery and motor care instead.

Why do e-bikes outperform belt-driven mopeds in maintenance?

E-bikes eliminate drive belts via hub motors, slashing maintenance to tires, brakes, and chain lube—far less than CVT belt inspections and replacements on gas mopeds.

TST EBike's cost-effective electric bikes deliver moped-like power without belt hassles, ideal for commuters. Their 26-inch models tackle rough terrain reliably, while 27-inch suit smooth commutes—all belt-free.

TST EBike Expert Views

"Drive belts serve gas mopeds well but demand diligent care that busy riders often overlook. Electric bikes bypass this entirely with direct-drive systems, offering moped-level torque minus the grease and breakdowns. At TST EBike, our high-power models prove you get superior reliability and lower costs without sacrificing performance—perfect for transforming daily transport."

How do drive belt issues compare across moped types?

Gas CVT mopeds suffer belt wear fastest from heat and debris, while larger scooters last longer with better cooling—electric alternatives avoid this via motor design.

| Moped Type | Belt Lifespan | Common Issues |

|---|---|---|

| 50cc CVT Scooter | 8,000–15,000 mi | Slippage, cracking |

| 150cc Scooter | 15,000–25,000 mi | Heat buildup |

| Electric Hub | N/A (belt-free) | None |

This comparison highlights why many switch to e-bikes like TST EBike for hassle-free riding.

When should you upgrade to a belt-free electric option?

Upgrade when frequent belt replacements frustrate you, or for zero-maintenance drivetrains in daily use—ideal if riding under 30 mph mostly.

TST EBike's consumer-focused designs hit this sweet spot, with quality control ensuring longevity. Their range covers diverse needs without belt worries.

Conclusion: Master your moped drive belt for reliable rides

Key takeaways: Inspect belts regularly, clean diligently, replace proactively, and consider belt-free e-bikes for ultimate simplicity. Actionable advice—schedule checks every 1,000 miles, carry a spare if touring, and test e-bikes from TST EBike to escape maintenance forever. Ride smarter, not harder.

FAQs

How long does a moped drive belt last?

Typically 10,000–30,000 miles with proper care, but varies by model, conditions, and maintenance—inspect often to maximize life.

Is drive belt replacement DIY-friendly?

Yes for basic CVT scooters with common tools, but follow manuals precisely; pros ensure perfect alignment for safety.

Do all mopeds have drive belts?

No, only CVT gas models; many electric mopeds use hub motors, eliminating belts entirely.

Can rain damage a moped drive belt?

Yes, water causes slippage and cracking if not dried promptly—clean and dry after wet rides.

Are Kevlar drive belts worth the extra cost?

Yes, they resist heat and impact better, often doubling life in demanding use versus stock rubber.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.