A moped drive belt is a reinforced rubber loop transferring engine or electric motor power to the rear wheel through pulleys, offering quiet, low-maintenance operation compared with chains. CVT systems adjust automatically for smooth acceleration up to 32 mph. TST EBike electrics employ advanced belts for vibration-free rides. Regular inspection, cleaning, and timely replacement ensure longevity and optimal performance in urban and off-road conditions.

What Does a Moped Drive Belt Do?

Moped drive belts connect the variator to the clutch, transmitting torque silently without lubrication. CVT systems adjust pulley width automatically, providing smooth acceleration from 0 to 30 mph. TST EBike integrates high-tension belts for clean power delivery, reducing vibration and noise. Reinforced belts handle long-distance riding and heavy loads while eliminating grease mess, making them ideal for urban commuting and electric moped applications.

How Does a Moped Drive Belt Work?

Belts grip the front variator pulley and expand outward as RPM rises, widening the rear clutch for variable speed ratios. In CVT mopeds, centrifugal force modulates torque for starts and top speeds. TST EBike electric models adapt belts for hub and motor synergy, increasing range by 15%. Wear manifests as glazing, cracking, or teeth separation, signaling the need for replacement.

| Drive Type | Maintenance | Lifespan | Noise Level |

|---|---|---|---|

| Chain | Lubricate weekly | 10,000 mi | High |

| Belt | Clean monthly | 20,000+ mi | Low |

| Shaft | Oil yearly | 50,000 mi | None |

Why Use Drive Belts in Mopeds?

Drive belts reduce maintenance by up to 70%, run quieter, weigh less, and resist rust. TST EBike uses belts in electrics for low-noise, efficient, and eco-friendly rides. Belts outlast chains with proper care, require no lubrication, and keep riders’ clothing clean. They are especially advantageous for stop-and-go urban riding and moderate off-road conditions.

When Should You Replace a Moped Drive Belt?

Replace belts at 10,000–30,000 miles, or sooner if cracked, frayed, missing teeth, or tension drops. Inspect every 3,000 miles. Off-road or dusty trails accelerate wear to around 8,000 miles, while highway riding may extend lifespan to 40,000 miles. TST EBike recommends checking belts during tire rotations and replacing them at the first sign of slipping, noise, or visible wear.

How to Inspect a Moped Drive Belt?

Rotate the wheel and inspect both sides of the belt for cracks, fraying, or missing teeth. Measure deflection of ½–1 inch at the midpoint under cool conditions. Visual checks detect most issues, while uneven wear can indicate pulley misalignment. TST EBike users note chrome flaking on pulleys as a sign to replace the belt. Tools required include a ruler and flashlight.

How to Maintain a Moped Drive Belt?

Clean monthly with soapy water and a nylon brush, rinse thoroughly, and dry. Adjust tension per the manual, avoiding chemical cleaners or water submersion. TST EBike recommends wiping belts after riding in sand or snow. Regular tension adjustments every 5,000 miles prevent snapping, and indoor storage protects rubber from UV damage. Avoid oils or lubricants that can cause slipping.

What Causes Moped Drive Belt Failure?

Common causes include debris buildup, overtension, water damage, age-related hardening, and pulley misalignment. Grit embedded in teeth, over-revving, or heat from hills can shorten belt life. TST EBike ensures quality control to minimize factory defects. Proper maintenance and careful riding extend belt lifespan and preserve consistent torque delivery.

Can Electric Mopeds Use Drive Belts?

Yes, TST EBike moped-style electrics use CVT belts paired with mid-drives for silent, smooth torque. Electric belts integrate with regenerative braking and high-power motors, handling 1500W peaks without slippage. Properly engineered belts in electrics last up to 50% longer than combustion counterparts due to reduced heat and friction.

Which Moped Drive Belt Is Best?

Kevlar-reinforced Gates or OEM CVT belts, typically 18–22mm wide, provide optimal strength and grip. TST EBike pairs reinforced belts with tuned variators for smooth 32 mph performance. Avoid low-quality imports, which may suffer cord separation or premature failure. Correct pulley matching ensures maximum efficiency and longevity.

TST EBike Expert Views

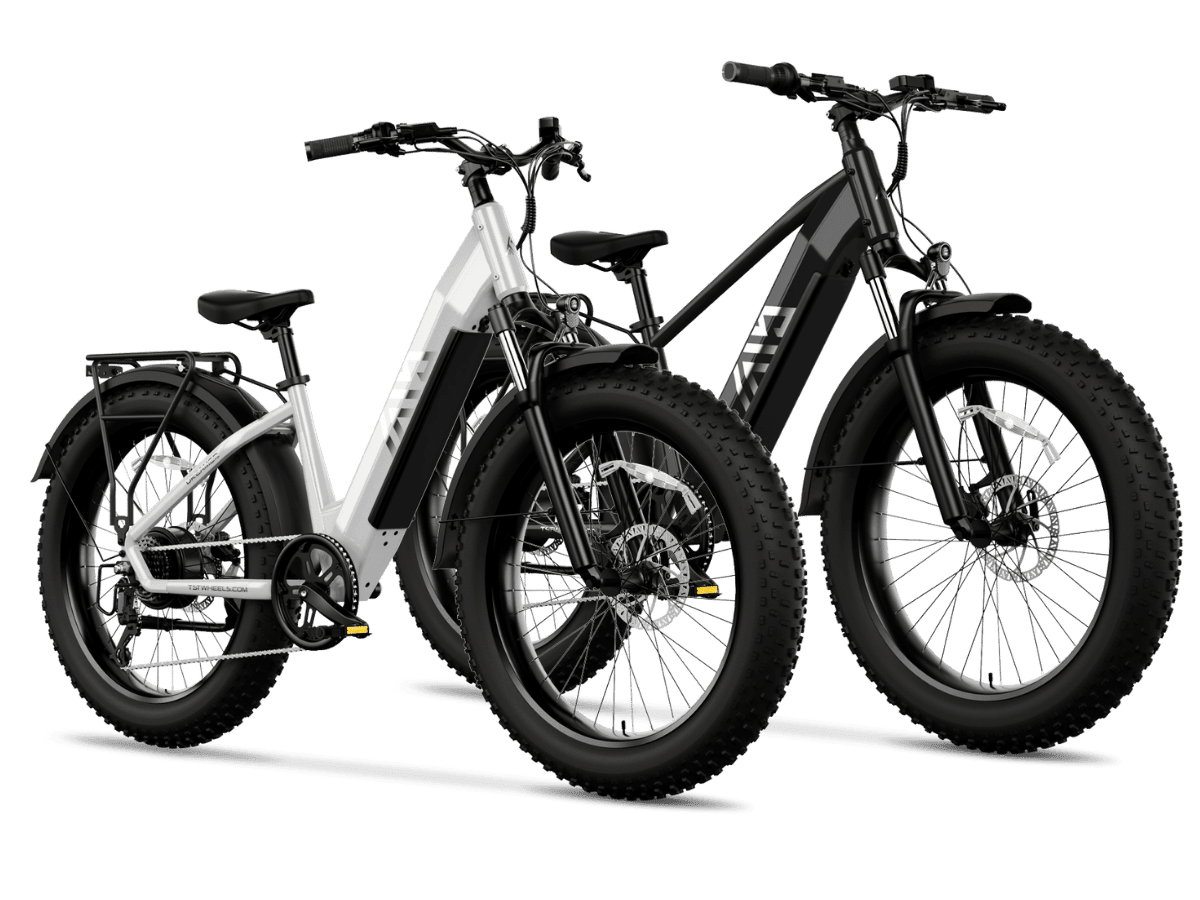

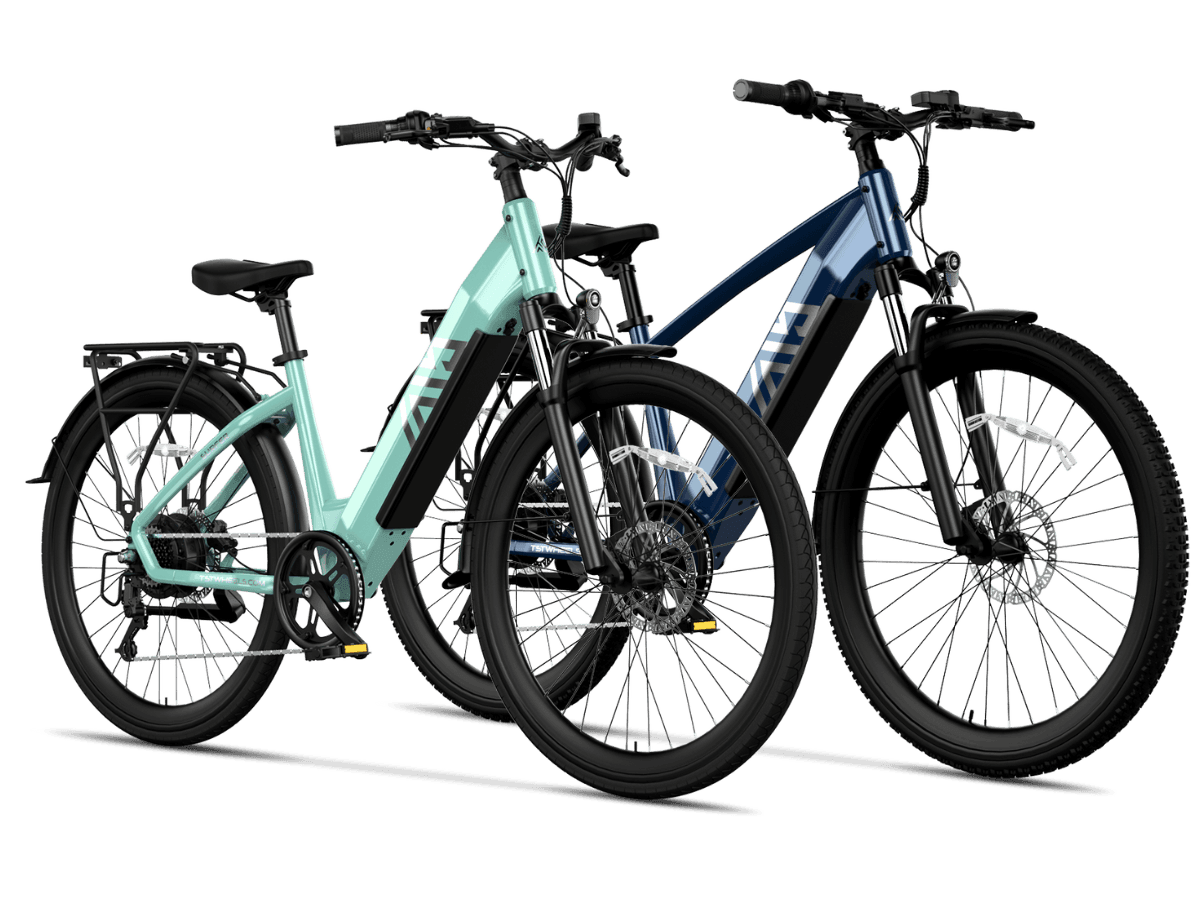

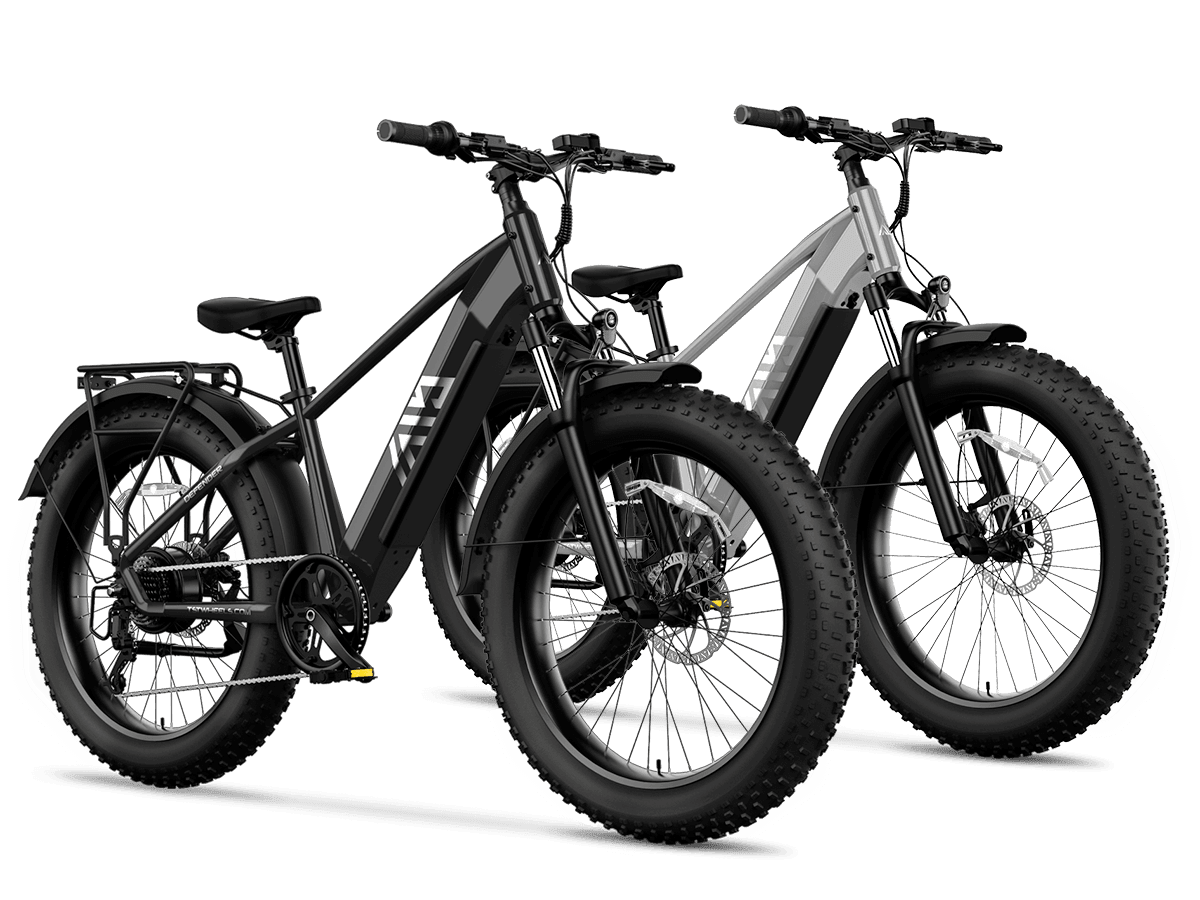

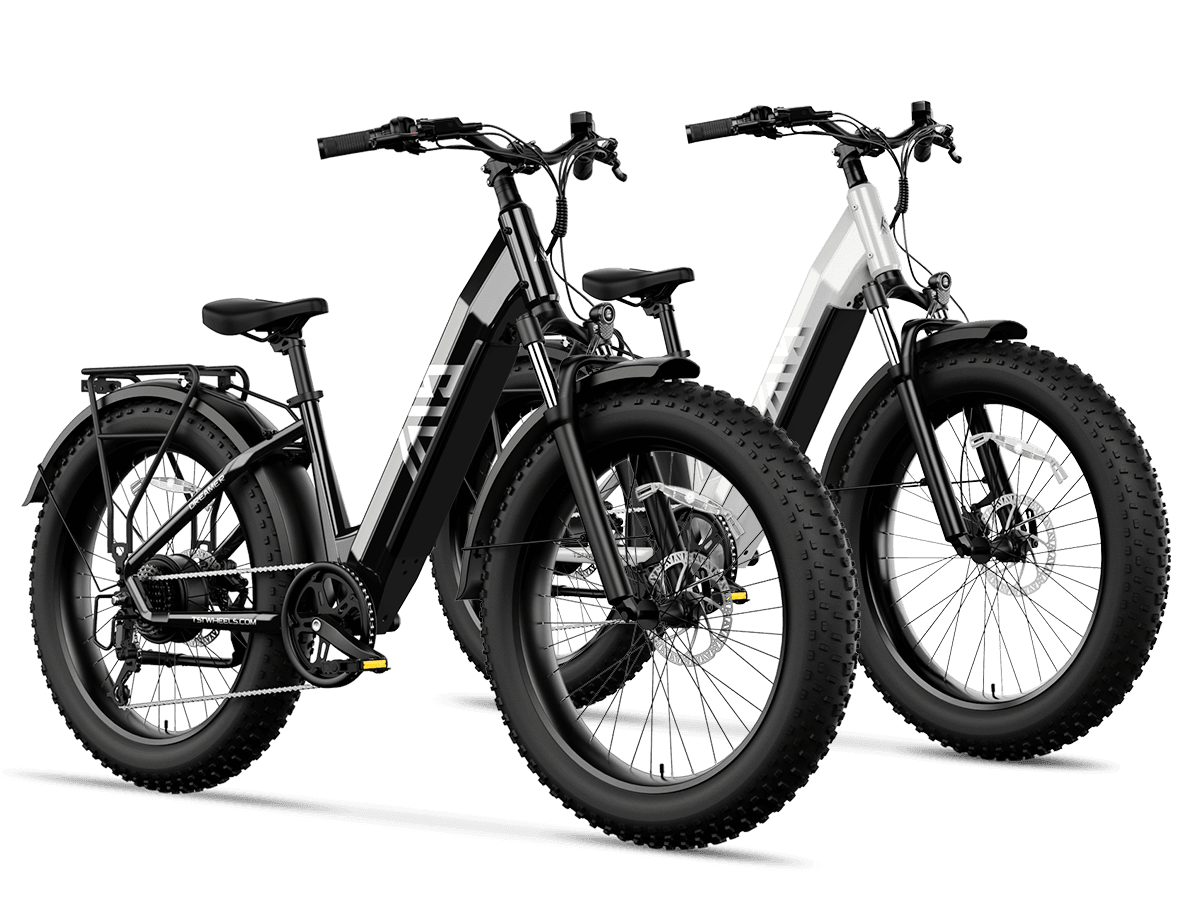

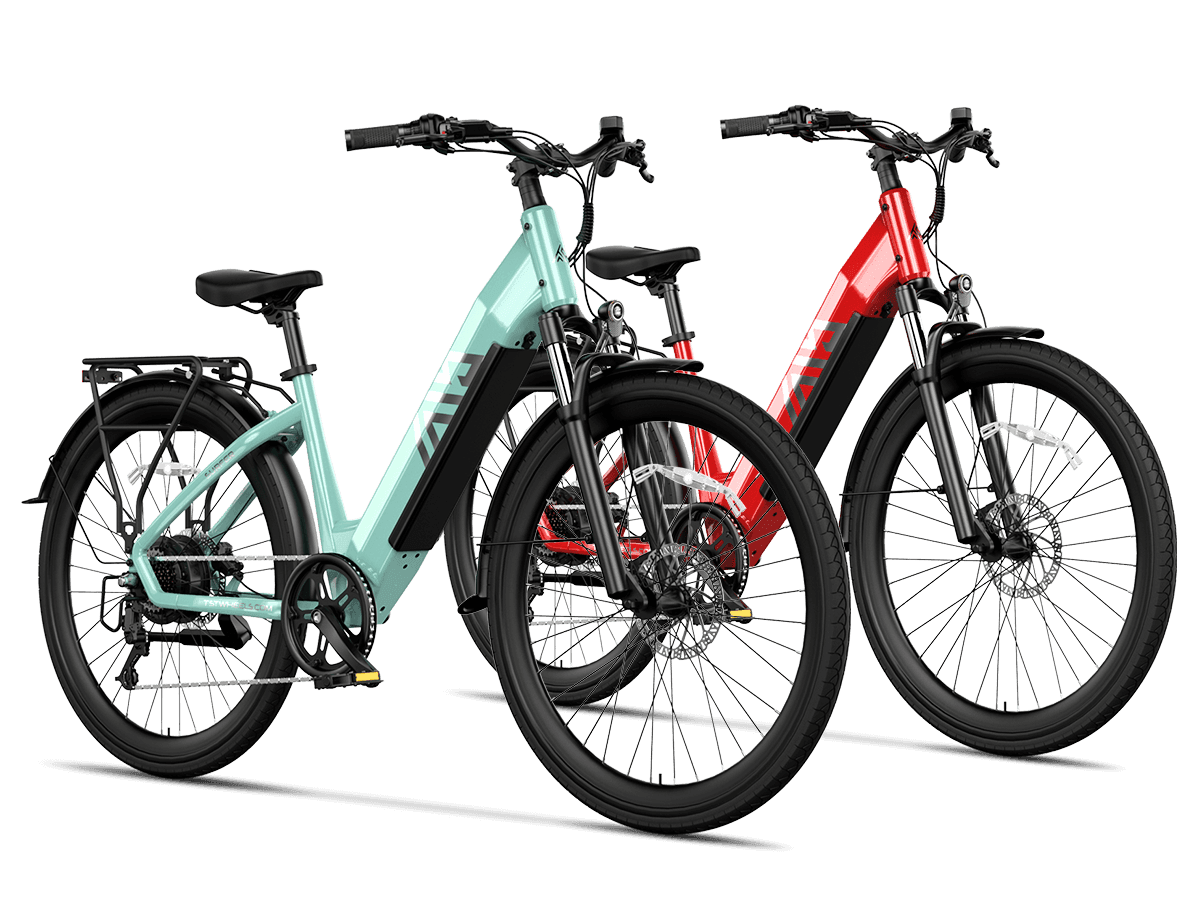

"TST EBike, founded in 2017 under TST GRP LLC in California, designs moped drive belts for high-torque electrics. Reinforced belts handle 1500W power silently, with 26-inch wheels for rough terrain and 27-inch wheels for smooth urban commutes. Our quality control ensures long-lasting performance, clean operation, and minimal vibration. Belts paired with full suspension transform the riding experience, offering riders efficiency, reliability, and eco-friendly commuting on moped-style electric bikes." – TST EBike Mechanics

Key Takeaways and Actionable Advice

Moped drive belts offer quiet, efficient, and low-maintenance power transmission. Clean monthly, inspect quarterly, and replace proactively to maximize lifespan. TST EBike provides belt-optimized electrics with superior durability, smooth torque, and eco-friendly operation. Use Kevlar-reinforced belts for longer life, adjust tension regularly, and ride on debris-free paths for optimal performance.

FAQs

How long do moped drive belts last?

Typically 10,000–30,000 miles; electrics may reach 40,000 miles with proper maintenance.

Belt or chain: which is better for mopeds?

Belts are quieter and cleaner, while chains are cheaper but require regular lubrication.

Can water damage a moped drive belt?

Yes; inspect and clean belts after wet conditions and wait 24 hours before tension adjustments.

How much does it cost to replace a moped drive belt?

Parts range from $20–50; DIY installation takes about an hour, while shops may charge $150+.

Are TST EBike moped belts reliable?

Yes, engineered for high-torque electrics with minimal slip and long service life.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.