Fat tire ebikes are perfect for heavy riders because their wide tires distribute weight evenly, provide excellent stability and traction, and enhance comfort on diverse terrains. Featuring reinforced frames and powerful motors, these bikes support higher weight capacities, ensuring safer, smoother rides for heavier individuals.

What Are the Key Benefits of Fat Tire Ebikes for Heavy Riders?

Fat tire ebikes offer enhanced stability and better weight distribution, crucial for heavy riders. Their wide tires provide superior traction on varied terrains, improving safety and control. The robust frame and suspension absorb shocks effectively, ensuring a comfortable ride. Additionally, fat tire ebikes often come with powerful motors capable of supporting heavier loads without performance loss, making them reliable for daily use and challenging conditions.

Fat tire ebikes offer heavy riders multiple advantages:

- Wide tires distribute weight evenly, reducing pressure points and increasing comfort.

- Large tire contact improves traction on slippery or uneven surfaces.

- Enhanced stability from a lower center of gravity and wider base.

- Strong frames and high-torque motors built to handle heavier weights.

- Suspension systems that absorb shocks for a smoother ride.

These combined features make fat tire ebikes an excellent choice for heavy riders seeking reliable performance and comfort.

Chart: Fat Tire Ebike Benefits for Heavy Riders

| Feature | Benefit |

|---|---|

| Wide Tires | Even weight distribution, superior traction |

| Reinforced Frame | Supports heavy loads, prevents bending |

| Powerful Motor | Provides torque for hills and speed |

| Suspension Fork | Absorbs shocks, enhances comfort |

| Low Tire Pressure | Improves grip and shock absorption |

How Do Fat Tire Ebikes Improve Stability and Safety for Heavy Riders?

Fat tire ebikes increase stability by spreading the rider’s weight over a larger surface area, which reduces tipping risks and improves balance. Their wide tires grip firmly on loose or uneven ground like sand, snow, or gravel, essential for heavier riders who need secure control. The sturdy frame and low center of gravity further enhance safe handling and reduce wobbling.

Which Features Should Heavy Riders Look for in a Fat Tire Ebike?

Heavy riders should prioritize strong frame construction, wide fat tires, and a high-capacity motor for reliable power. A sturdy suspension system is essential for shock absorption and comfort. Look for models with reinforced wheels and high weight limits. Comfortable seating and adjustable handlebars also enhance the ride experience. Battery capacity should support extended rides despite heavier loads, ensuring consistent power and durability.

Heavy riders should prioritize:

- Durable frame materials such as aluminum or chromoly steel.

- Motors with at least 750W power for sufficient torque.

- Tires 4 inches or wider for better weight distribution and traction.

- Suspension forks designed to absorb bumps.

- High-capacity batteries (15Ah or more) for longer rides.

These features ensure the bike can support heavier riders comfortably and efficiently.

Why Are Fat Tire Ebikes Suitable for Off-Road and All-Terrain Riding by Heavy Riders?

Fat tire ebikes excel off-road due to their oversized tires that maintain grip and balance on challenging surfaces like mud, sand, snow, and rocks. Running at lower tire pressures increases shock absorption, reducing impact on rough terrain. Powerful motors help heavy riders conserve energy climbing hills or covering long distances. Suspension forks and an upright riding position improve control and comfort, making fat tire ebikes ideal for adventurous heavy riders.

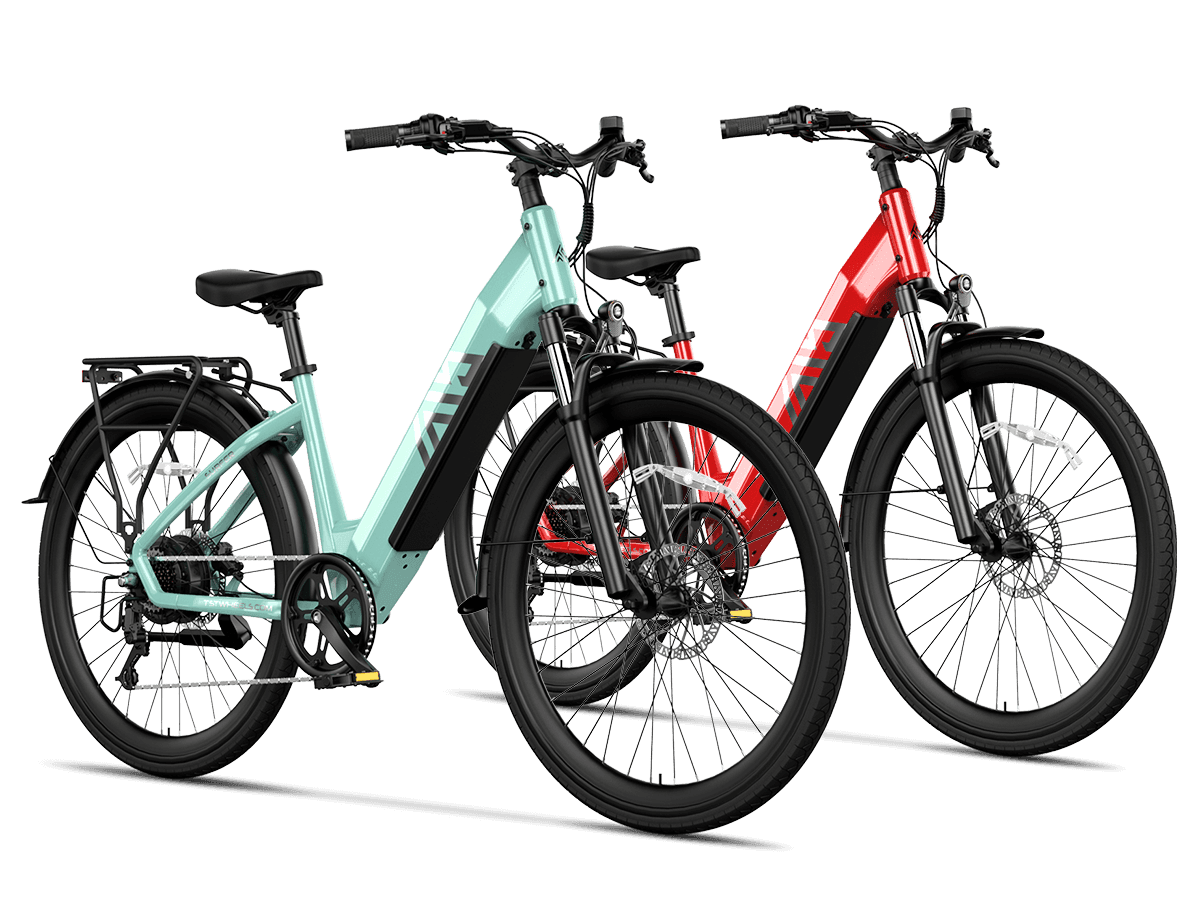

How Does TST EBike Cater to Heavy Riders with Fat Tire Models?

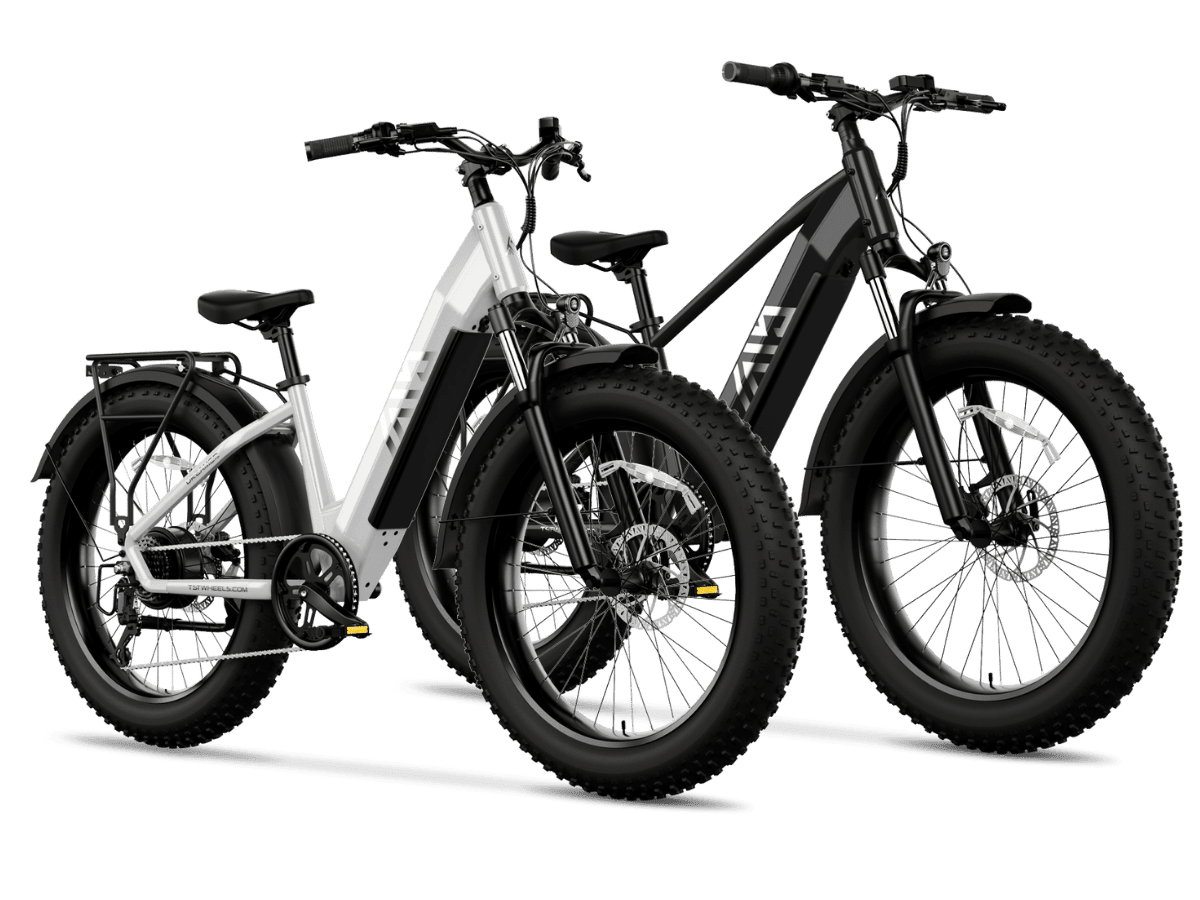

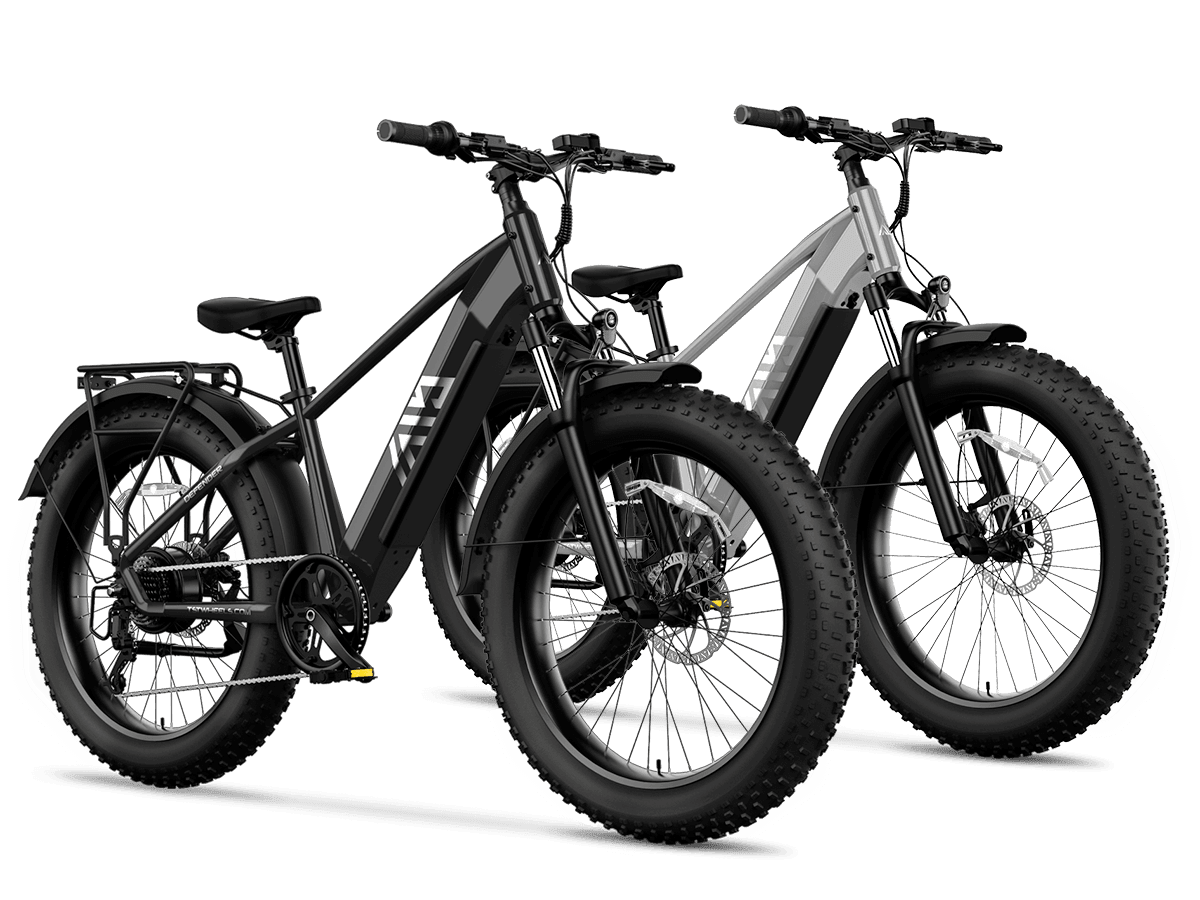

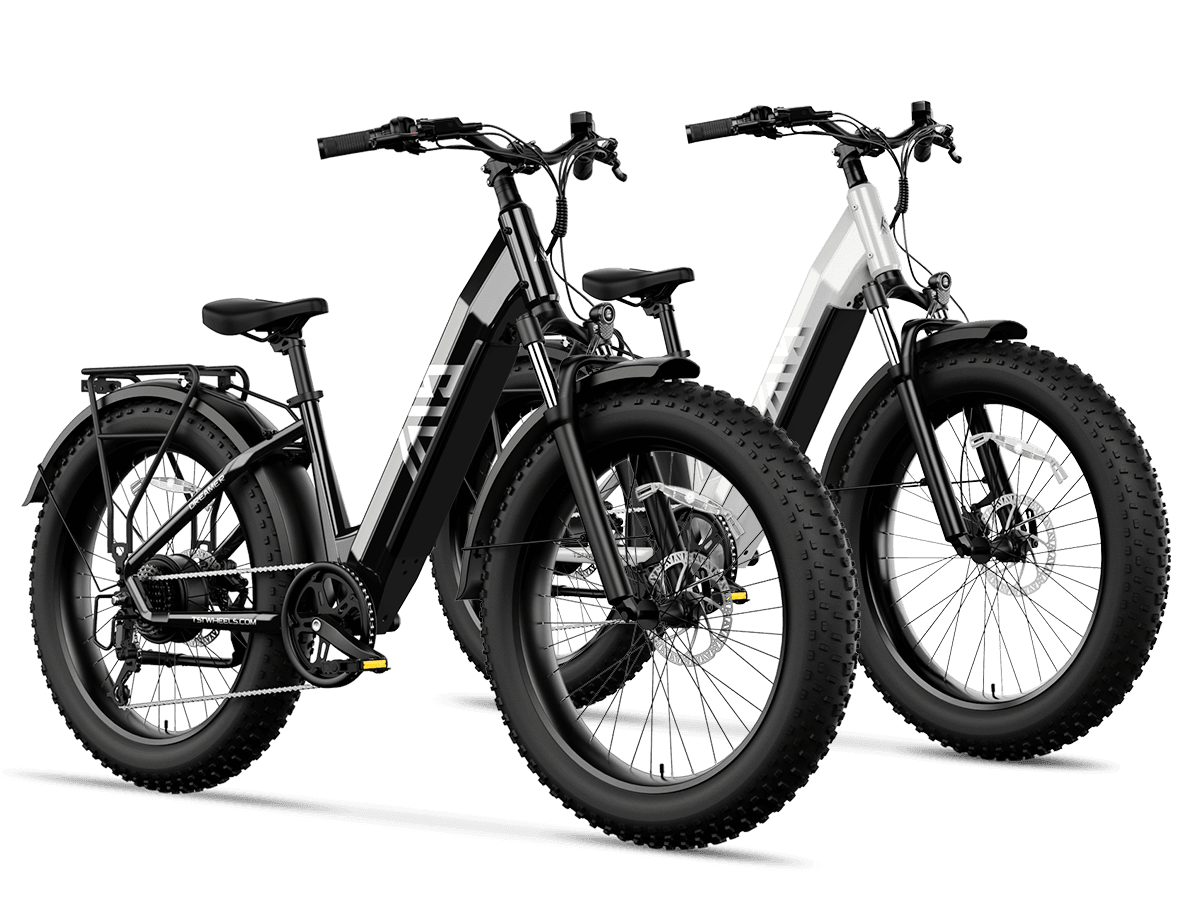

TST EBike designs fat tire models with reinforced frames and powerful 1300W motors to support heavier riders. Their fat tires offer excellent grip and stability across terrains. The suspension systems are optimized for comfort under weight stress, while the durable components ensure long-term reliability. TST also provides higher weight capacity specifications and battery options suited to maintain performance during extended rides with heavier loads.

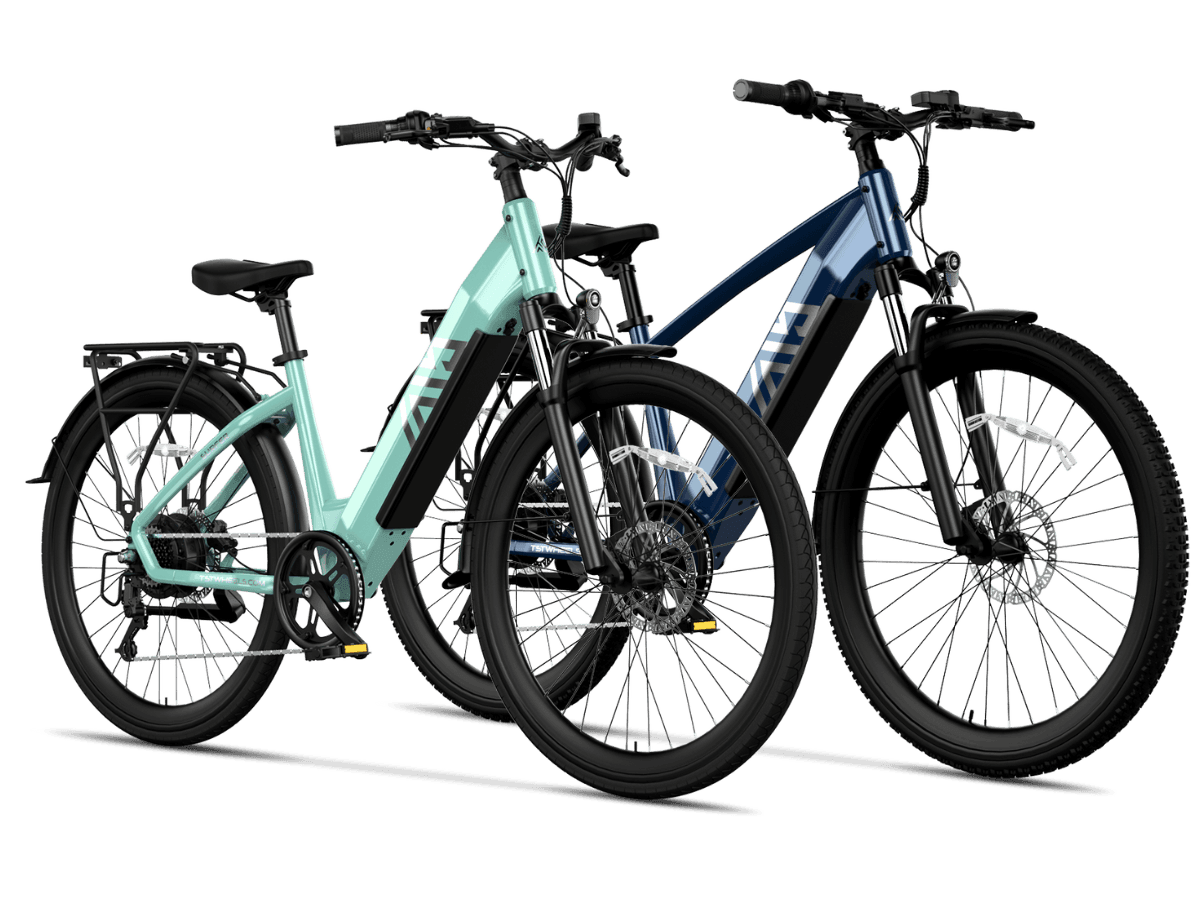

TST EBike designs fat tire ebikes with consumer feedback to meet heavy riders’ needs. Their models feature:

- High-power motors and reinforced frames for durability.

- 26-inch fat tire models for rough terrains like snow and sand.

- 27-inch fat tire models for daily commuting and mountain biking.

- Affordable pricing combined with strict quality control.

TST EBike offers high-quality, cost-effective fat tire ebikes that deliver durability and versatility for heavy riders.

Buying Tips

When buying a fat tire ebike for heavy riders, keep these points in mind:

- Confirm the bike’s maximum weight capacity (aim for 400 lbs+).

- Choose a reinforced frame made of aluminum or chromoly steel.

- Select a motor with at least 750W power for adequate torque.

- Opt for wide tires (4 inches or more) and suspension forks for comfort and stability.

- Ensure the battery capacity supports longer rides without frequent charging.

- Test ride to check comfort, handling, and fit.

Following these tips will help you find a fat tire ebike that supports your weight safely while providing a smooth, stable ride.

TST EBike Expert Views

“TST EBike’s fat tire models are crafted for heavier riders, combining robust frames and powerful motors with wide tires that improve traction and comfort. Our 26-inch and 27-inch models cover everything from rugged terrain to everyday commuting, offering a reliable and affordable ride designed around the needs of heavier users.” – TST EBike Product Specialist

FAQ

Can fat tire ebikes support riders over 350 lbs?

Yes, many fat tire ebikes have reinforced frames and wide tires designed to safely support weights up to 400-500 lbs.

Do heavy riders use more battery power on fat tire ebikes?

Heavier riders may drain batteries faster, especially on hills or rough terrain, so choosing a high-capacity battery is advisable.

Are fat tire ebikes harder to pedal without electric assist?

Fat tires increase rolling resistance, making pedaling harder without assist; however, the motor compensates for this effort.

What terrains can fat tire ebikes handle for heavy riders?

They perform well on sand, snow, mud, gravel, and rocky trails, providing stability and traction where standard tires struggle.

Fat tire ebikes are an excellent choice for heavy riders seeking stability, comfort, and durability on various terrains. With models like those from TST EBike, heavy riders can enjoy safer, more enjoyable cycling experiences tailored to their needs.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.