Hydraulic brakes on a fat tire ebike provide superior stopping power, precise control, and reliable performance in all weather conditions. Their smooth modulation reduces hand fatigue during long rides, while their sealed system resists dirt and moisture, making them low maintenance and highly durable—essential qualities for the heavy loads and diverse terrains fat tire ebikes encounter.

How Do Hydraulic Brakes Enhance Stopping Power on Fat Tire Ebikes?

Hydraulic brakes use fluid pressure to amplify braking force, delivering stronger and more consistent stopping power compared to mechanical brakes. This is critical for fat tire ebikes, which are heavier and often ridden at higher speeds. The increased braking efficiency allows riders to stop quickly and safely, even on steep descents or slippery surfaces like snow and mud.

Chart: Hydraulic vs Mechanical Brakes - Stopping Power Comparison

| Brake Type | Stopping Power | Effort Required | Performance in Wet Conditions |

|---|---|---|---|

| Hydraulic Brakes | Superior | Low | Excellent |

| Mechanical Brakes | Moderate | Higher | Reduced |

What Makes Hydraulic Brakes More Precise and Comfortable?

Hydraulic systems provide smooth and precise modulation, allowing riders to finely control braking force. This improved modulation helps maintain traction and prevents wheel lockup, especially important on loose or uneven terrain common for fat tire ebikes. Additionally, hydraulic brake levers require less hand effort, reducing fatigue during long rides or frequent braking.

Why Are Hydraulic Brakes More Reliable in All Weather Conditions?

Unlike mechanical brakes, hydraulic brakes are sealed systems that keep out dirt, water, and debris. This protects the internal components from contamination, ensuring consistent braking performance in rain, mud, snow, or dust. Their reliability in adverse conditions enhances rider safety and confidence regardless of the environment.

How Do Hydraulic Brakes Reduce Maintenance and Increase Durability?

Hydraulic brakes have fewer exposed moving parts and self-adjust automatically as brake pads wear, minimizing the need for frequent tuning or cable replacements. Their sealed fluid system resists corrosion and contamination, extending component lifespan. This durability is especially beneficial for fat tire ebikes, which often face rugged terrain and heavy use.

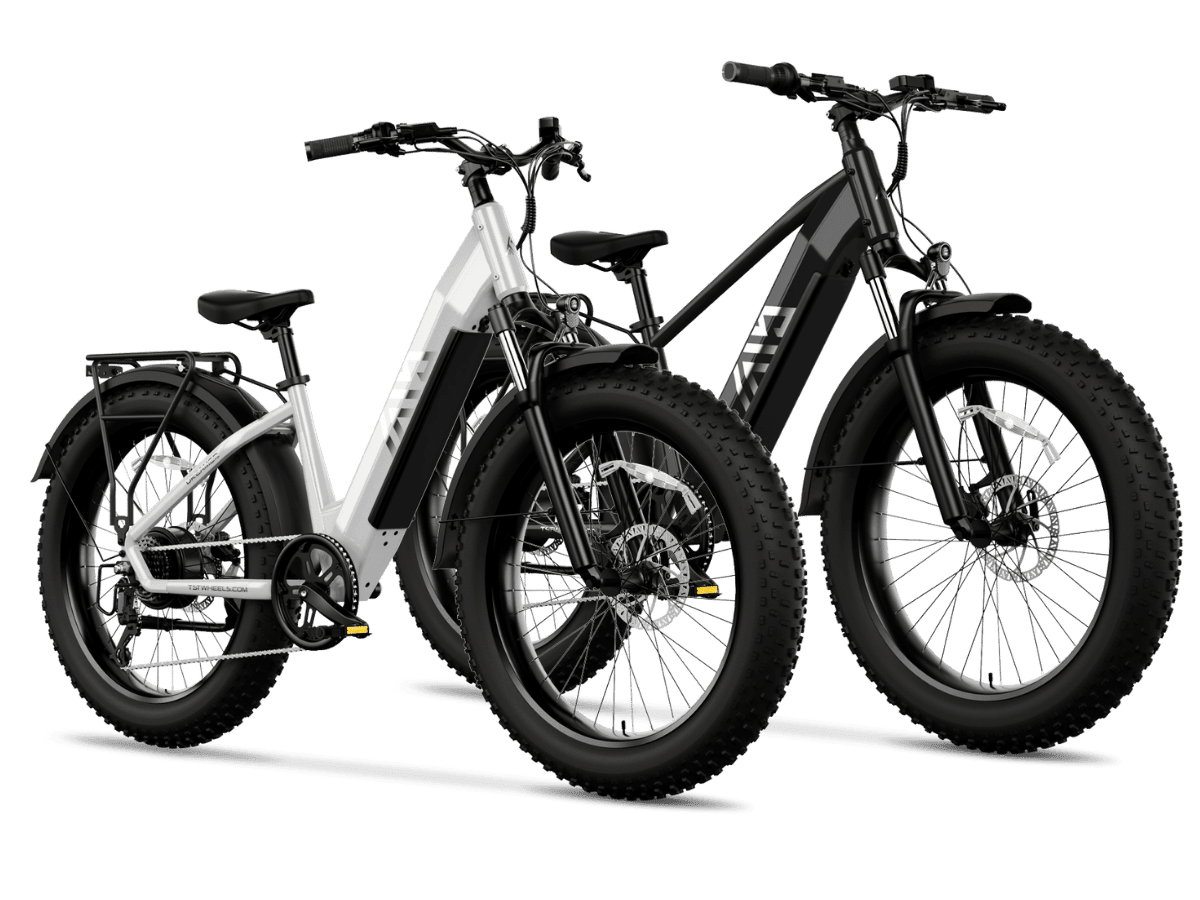

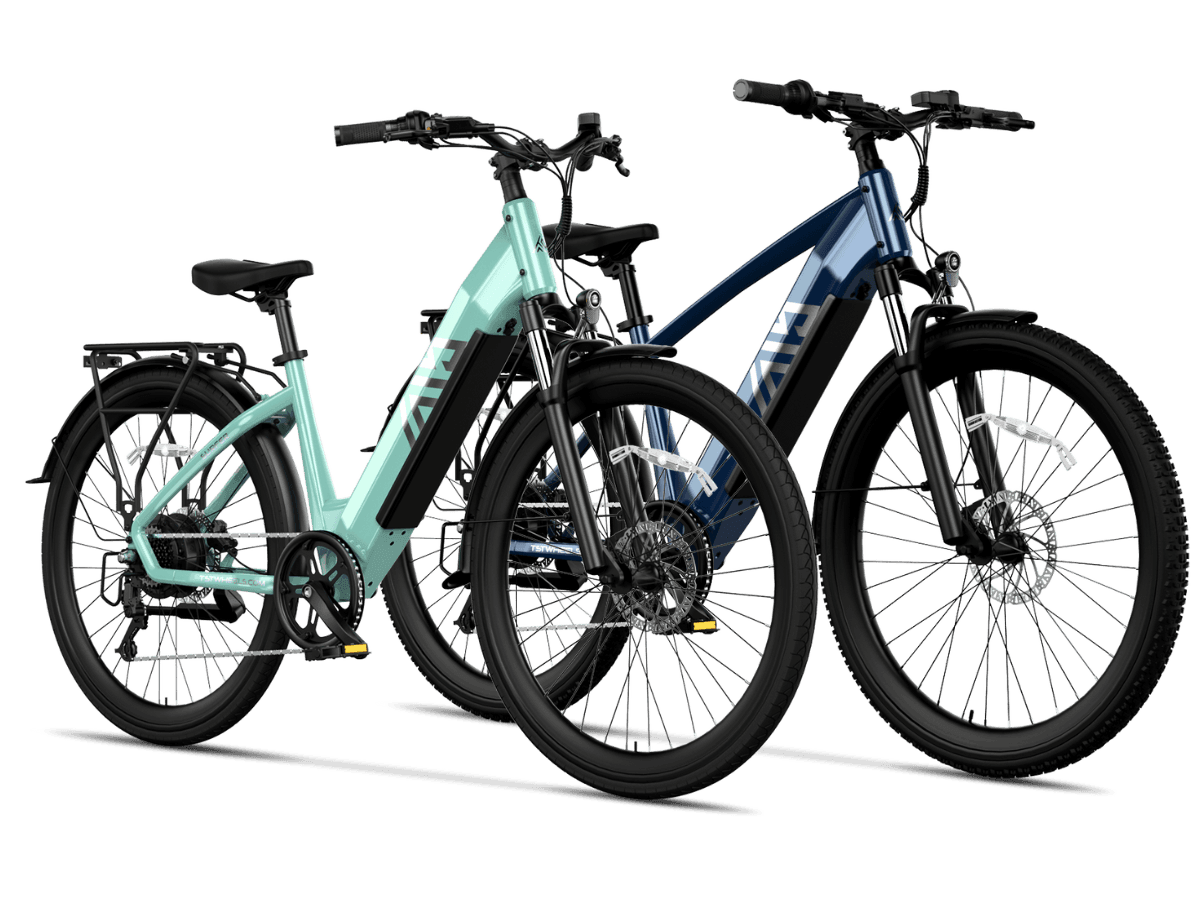

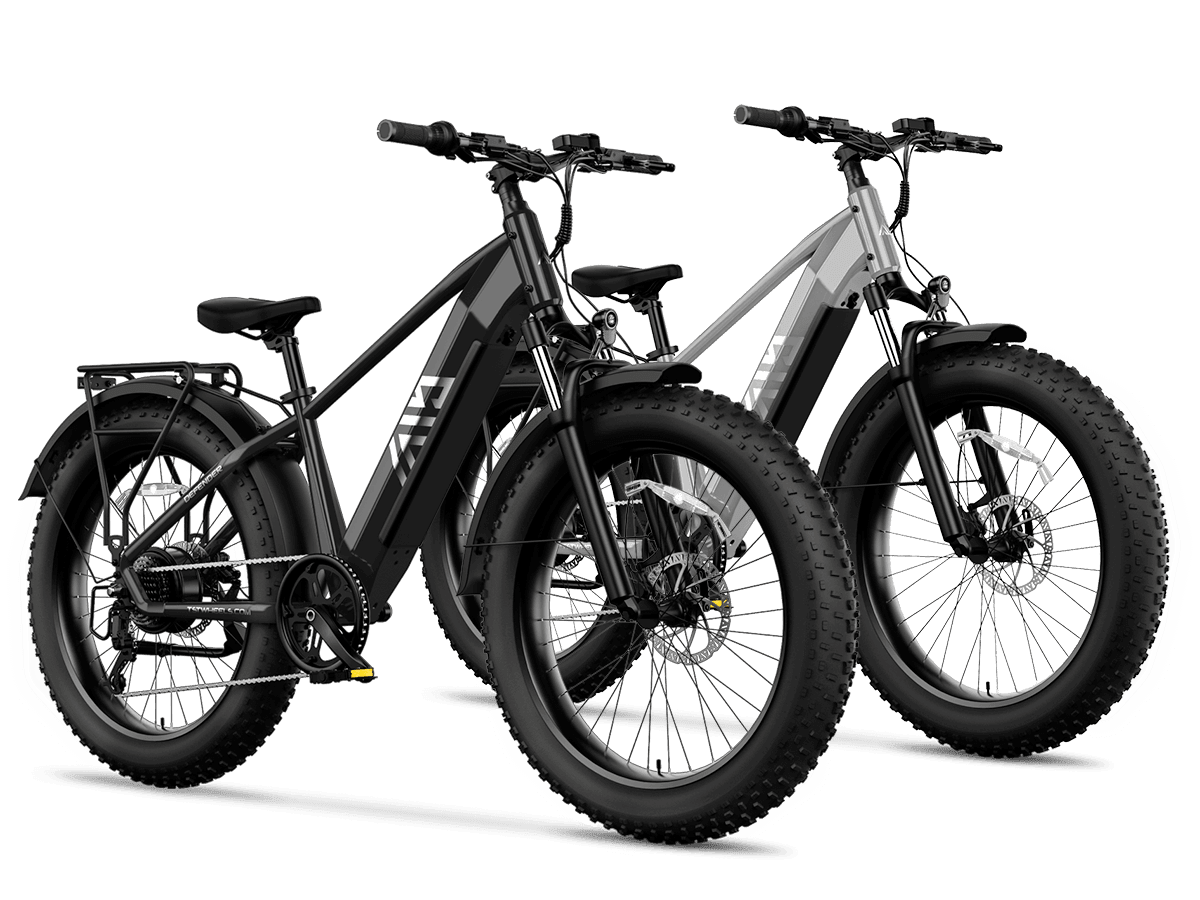

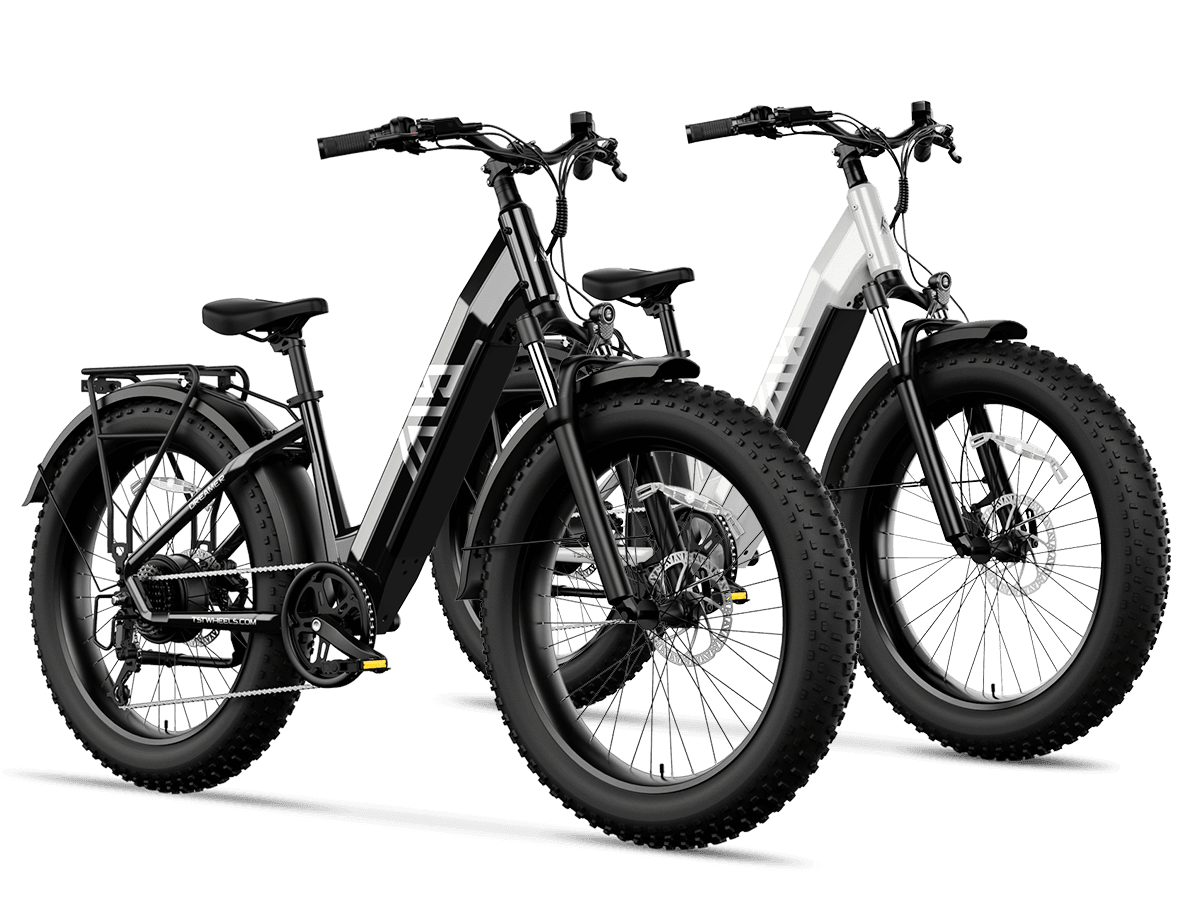

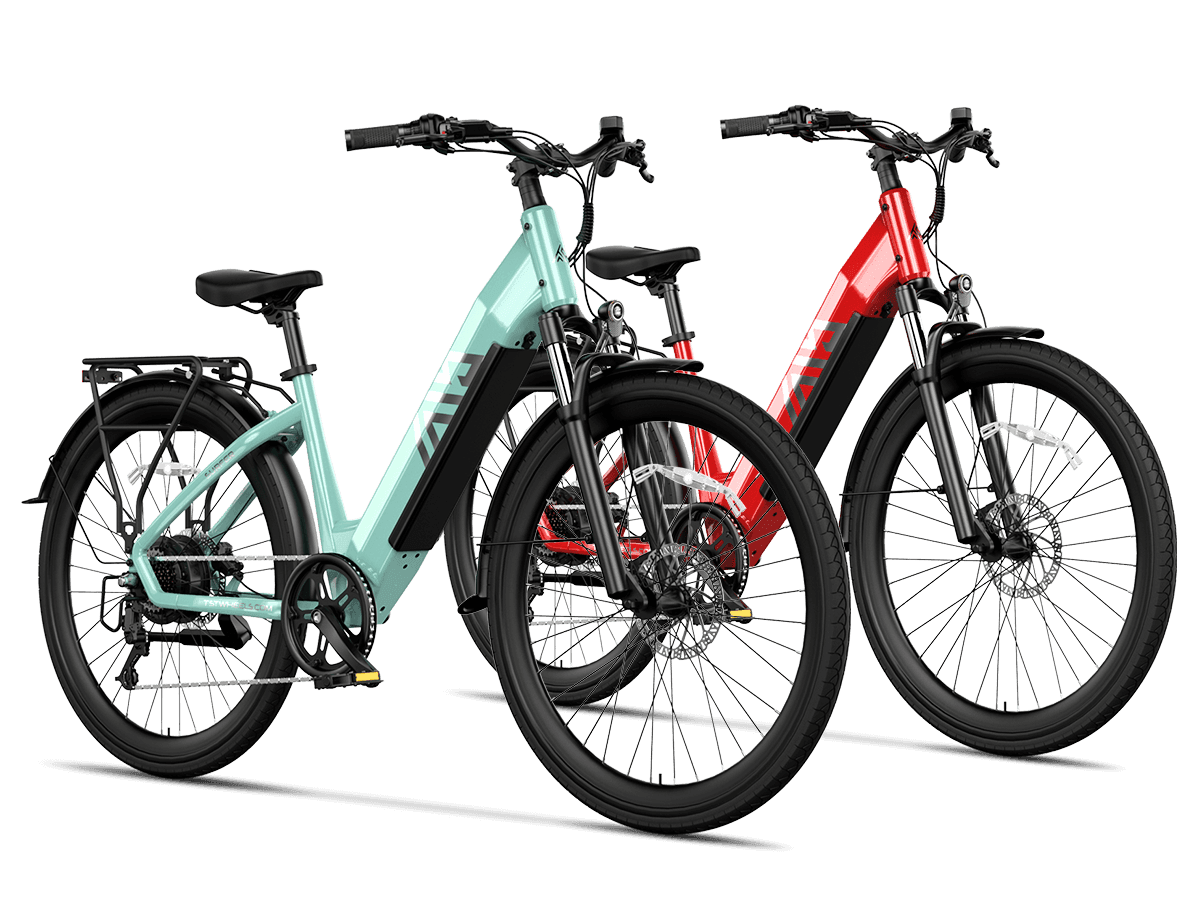

Why Are Hydraulic Brakes Essential for High-Performance Fat Tire Ebikes Like TST EBike?

TST EBike equips its fat tire models with hydraulic disc brakes to match the power and weight of their 1300W motors and wide tires. These brakes provide the stopping power and modulation needed for safe, confident riding on snow, sand, and mountain trails. Combined with durable frames and high-capacity batteries, hydraulic brakes help TST EBike deliver reliable, high-performance ebikes suited for demanding conditions.

Buying Tips

When choosing hydraulic brakes for a fat tire ebike, consider:

- Opt for models with 4-piston calipers for stronger braking power.

- Check for compatibility with your bike’s tire size and frame.

- Look for brands with good heat dissipation to prevent brake fade.

- Ensure the system uses quality mineral or DOT brake fluid.

- Consider ease of maintenance and availability of replacement parts.

- Test brake modulation and lever comfort during a test ride.

These tips help you select hydraulic brakes that offer safety, comfort, and durability for your fat tire ebike.

TST EBike Expert Views

“Hydraulic brakes are critical for fat tire ebikes, providing the powerful, consistent stopping force needed to control heavier bikes on challenging terrain. Our models use advanced hydraulic systems paired with wide tires and strong motors to ensure riders experience smooth modulation, reduced hand fatigue, and reliable braking in all conditions.” – TST EBike Product Specialist

FAQ

Are hydraulic brakes better than mechanical brakes on fat tire ebikes?

Yes, hydraulic brakes offer stronger, smoother, and more reliable stopping power with less maintenance.

Do hydraulic brakes work well in wet or muddy conditions?

Absolutely, their sealed system keeps contaminants out, maintaining braking performance in all weather.

Are hydraulic brakes harder to maintain?

They require less frequent adjustment but may need occasional fluid bleeding, which is straightforward with proper tools.

Can hydraulic brakes reduce hand fatigue on long rides?

Yes, they require less lever force, making braking more comfortable over extended periods.

Hydraulic brakes uniquely combine power, precision, and durability, making them the ideal braking system for fat tire ebikes. With models like those from TST EBike, riders gain enhanced safety and control across all terrains and conditions.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.